Daikin Semi-Custom Outdoor Air Handler Skyline OAC/OAH: Every 2000 Hours Maintenance

This procedure if for your equipment's supply and return fans—Supply and return fan motors should have grease added after every 2000 hours of operation. This will help maintain your equipment's stability and high performance.

Daikin Semi-Custom Outdoor Air Handler Skyline OAC/OAH: Every 2000 Hours Maintenance

This procedure if for your equipment's supply and return fans—Supply and return fan motors should have grease added after every 2000 hours of operation. This will help maintain your equipment's stability and high performance.

Motor Bearings

Supply and return fans—Supply and return fan motors should have grease added after every 2000 hours of operation. Using the following procedure, re-lubricate the bearings while the motor is warm, but not running.

NOTE: Direct Drive Class II fans that are supplied with TECO motors have double shielded bearings on frame sizes 140T-280T. These bearings are pre-packed with a long life grease and are not re-greaseable. Larger frame size TECO motors are re-greaseable and follow the same lubrication recommendations as all other motors.

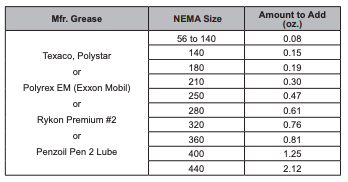

Use one of the greases shown in Table 32.

Fan Shaft Bearings

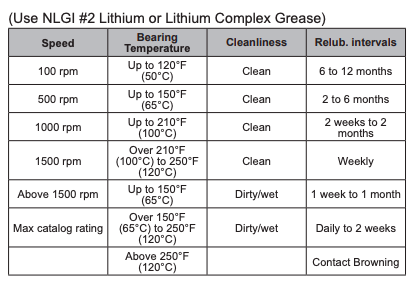

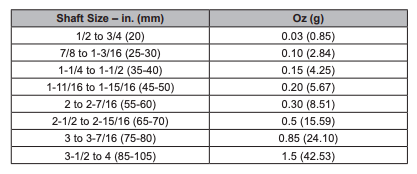

Any good quality lithium or lithium complex base grease, using mineral oil, conforming to NLGI grade 2 consistency, and an oil viscosity of 455-1135 SUS at 100°F (100-200 cSt at 40°C) may be used for re-lubrication.

Compatibility of grease is critical. Re-lubricatable bearings are supplied with grease fittings or zerks for ease of lubrication with hand or automatic grease guns. Always wipe the fitting and grease nozzle clean.

Source: Daikin (oslo.daikinapplied.com)