Precedent® (TSC036G - TSC060G, TSC072H - TSC120H, THC036E - THC072E, THC037E - THC067E, THC048F - THC120F)Rooftop Units: Periodic Maintenance

This procedure is for the periodic maintenance of your equipment. It focuses on Fan Belt Adjustments.

Precedent® (TSC036G - TSC060G, TSC072H - TSC120H, THC036E - THC072E, THC037E - THC067E, THC048F - THC120F)Rooftop Units: Periodic Maintenance

This procedure is for the periodic maintenance of your equipment. It focuses on Fan Belt Adjustments.

Maintenance

! WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on the tags, stickers, and labels could result in death or serious injury.

Technicians, in order to protect themselves from potential electrical, mechanical, and chemical hazards, MUST follow precautions in this manual and on the tags, stickers, and labels, as well as the following instructions: Unless specified otherwise, disconnect all electrical power including remote disconnect and discharge all energy storing devices such as capacitors before servicing.

Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized. When necessary to work with live electrical components, have a qualified licensed electrician or other individual who has been trained in handling live electrical components perform these tasks.

Fan Belt Adjustment - Belt Drive Units

! WARNING

Live Electrical Components!

Failure to follow all electrical safety precautions when exposed to live electrical components could result in death or serious injury. When necessary to work with live electrical components, have a qualified licensed electrician or other individual who has been properly trained in handling live electrical components perform these tasks.

! WARNING

Rotating Components!

Failure to follow all safety precautions below could result in rotating components cutting and slashing technician which could result in death or serious injury.

During installation, testing, servicing and troubleshooting of this product it may be necessary to work with live and exposed rotating components. Have a qualified or licensed service individual who has been properly trained in handling exposed rotating components, perform these tasks.

The fan belts must be inspected periodically to assure proper unit operation.

Replacement is necessary if the belts appear frayed or worn. Units with dual belts require a matched set of belts to ensure equal belt length.

When removing or installing the new belts, do not stretch them over the sheaves. Loosen the belts using the belt tension adjustment bolts on the motor mounting base.

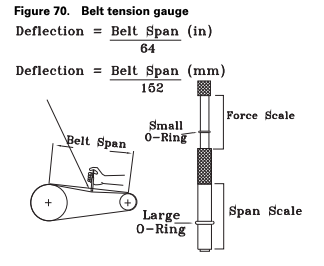

Once the new belts are installed, using a Browning or Gates tension gauge (or equivalent) illustrated in Figure 70, p. 66; adjust the belt tension as follows:

Table 19. Belt tension measurement and deflection

Source: Trane (www.trane.com)