Doosan D15S-5 Pneumatic Forklift 2500 Hours/ 15 Months

The Doosan D15S-5 Pneumatic Forklift 2500 Hours/ 15 Months is a preventive maintenance form that keeps your forklift in prime working condition. Maximize your forklifts capabilities by consistently performing maintenance.

Doosan D15S-5 Pneumatic Forklift 2500 Hours/ 15 Months

The Doosan D15S-5 Pneumatic Forklift 2500 Hours/ 15 Months is a preventive maintenance form that keeps your forklift in prime working condition. Maximize your forklifts capabilities by consistently performing maintenance.

You must read and understand the warnings and instructions contained in the Safety section of this manual, before performing any operation or maintenance procedures.

Hydraulic Oil - Change, Check, Clean

WARNING: Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Park the lift truck level with the forks lowered, park- ing brake engaged, transmission in NEUTRAL and the engine stopped.

Inspect Battery System

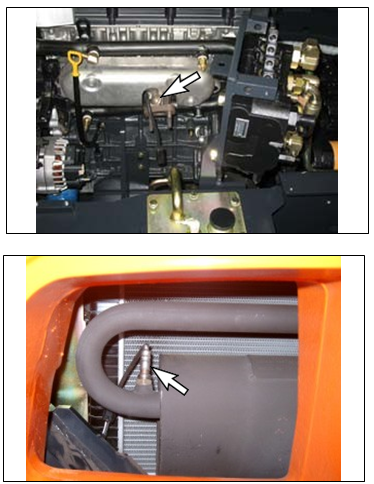

Replace Oxygen Sensor (G420F(E) Engine Only)

When indicated by MIL, replace oxygen seasor on the exhaust manifold and oxygen sensor on muffler assembly.

WARNING: When assembling the filters, check the arrow mark on the filter surface. The arrow mark position is same as fuel flow direction.

Checking the TMAP Sensor (G420F(E) Engine Only)

Inspect for Intake Leaks (G420F(E) Engine Only)

Replace PCV Valve and breather element (LP-Gas, Gasoline and Dual Fuel Engines) - Change

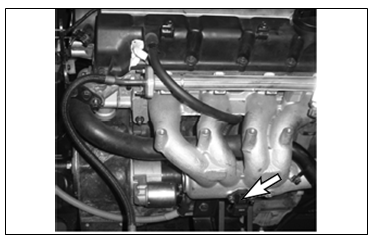

Replace Spark Plugs (G420F(E) Engine Only)

WARNING: DO NOT OVER TIGHTEN THE SPARK PLUGS.

(1) Ignition wiring harness (2) Ignition Coil Assy (3) Spark plug

Source: Doosan