Rheem RH2T Air Handlers Unit Yearly Maintenance

The Rheem RH2T Air Handlers Unit Yearly Maintenance covers all major components of your machine. Before performing any service or maintenance procedures, see the “Safety Information” section at the front of this manual.

Rheem RH2T Air Handlers Unit Yearly Maintenance

The Rheem RH2T Air Handlers Unit Yearly Maintenance covers all major components of your machine. Before performing any service or maintenance procedures, see the “Safety Information” section at the front of this manual.

For continuing high performance, and to minimize possible equipment failure, it is essen- tial that periodic maintenance be performed on this equipment. Consult your local dealer as to the proper frequency of maintenance and the availability of a maintena

IMPORTANT: Before performing any service or maintenance procedures, see the “Safety Information” section at the front of this manual.

WARNING: Units with circuit breaker(s) meet requirements as a service disconnect switch, however, if access is required to the line side (covered) of the circuit breaker, this side of the breaker(s) will be energized with the breaker(s) de-energized. Cont

12.1 AIR FILTER (NOT FACTORY-INSTALLED)

Check the system filter every ninety days or as often as found to be necessary and if obstructed, clean or replace at once.

FILTER MAINTENANCE

IMPORTANT: Do not operate the system without a filter in place

12.2 INDOOR COIL - DRAIN PAN - DRAIN LINE

Inspect the indoor coil once each year for cleanliness and clean as necessary. In some cases, it may be necessary to remove the filter and check the return side of the coil with a mirror and flashlight.

IMPORTANT: Do not use caustic household drain cleaners, such as bleach, in the condensate pan or near the indoor coil. Drain cleaners will quickly damage the indoor coil.

12.3 BLOWER MOTOR AND WHEEL

Inspect the blower motor and wheel for cleanliness. It should be several years before it would become necessary to clean the blower motor and wheel.

12.4 LUBRICATION

12.5 BLOWER ASSEMBLY REMOVAL AND REPLACEMENT

WARNING: If removal of the blower assembly is required, all disconnect switches supplying power to the equipment must be de-energized and locked (if not in sight of unit) so the field power wires can be safely removed from the blower assembly. Failure to

12.6 MOTOR REPLACEMENT

With the blower assembly removed, the indoor blower motor can be removed and replaced using the following procedure:

WARNING: To avoid electrical shock which can result in personal injury or death, use only the screws furnished in the motor shell mounting holds. Screws are #8-18 x .25 in. long blunt nose thread forming. Screws longer than 1/4 in. may contact the motor w

12.7 BLOWER WHEEL REPLACEMENT

With the blower assembly removed and the motor assembly removed (see above instructions), remove the 4 screws holding the blower wrap (cutoff) to the blower sides.

13.0 REPLACEMENT PARTS

These parts include but are not limited to:

When ordering replacement parts, it is necessary to order by part number and include with the order the complete model number and serial number from the unit data plate. (See parts list for unit component part numbers).

14.0 ACCESSORIES-KITS-PARTS

NOTE: No jumper bar kit is available to convert three phase multiple two circuit units to a single supply circuit.

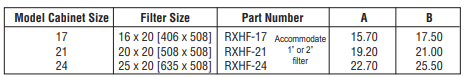

FIGURE 30 EXTERNAL FILTER BASE: RXHF

FIGURE 31 EXTERNAL FILTER RACK: RXHF- B17, B21, B2

Source: Rheem