Water-Cooled Helical Rotary Chiller Series R: Weekly Maintenance and Checks

This procedure is the recommended weekly maintenance procedure for your equipment. Performing all maintenance procedures and inspection at the recommended intervals will prolong the life of your chiller and minimize the possibility of malfunctions.

Water-Cooled Helical Rotary Chiller Series R: Weekly Maintenance and Checks

This procedure is the recommended weekly maintenance procedure for your equipment. Performing all maintenance procedures and inspection at the recommended intervals will prolong the life of your chiller and minimize the possibility of malfunctions.

Overview

An important aspect of the chiller maintenance program is the regular completion of operator logs. See “Log and Check Sheets,” p. 157 for an example. When filled out properly the completed logs can be reviewed to identify any developing trends in the chiller's operating conditions

This section describes preventative maintenance procedures and intervals. Use a periodic maintenance program to ensure optimal performance and efficiency of the Series R units.

Maintenance

! WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could result in death or serious injury. Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized.

! WARNING

Live Electrical Components!

Failure to follow all electrical safety precautions when exposed to live electrical components could result in death or serious injury. When necessary to work with live electrical components, have a qualified licensed electrician or other individual who has been properly trained in handling live electrical components perform these tasks.

Weekly Maintenance and Checks

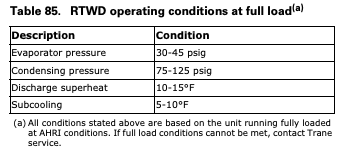

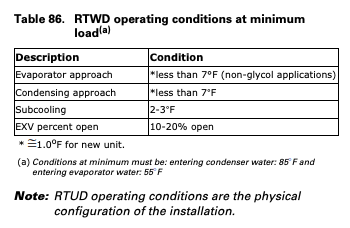

After the unit has operated for approximately 30 minutes and the system has stabilized, check the operating conditions and complete the procedures below:

Note: For RTWD units, optimum condenser pressure is dependent on condenser water temperature, and should equal the saturation pressure of the refrigerant at a temperature 2 to 5F above that of leaving condenser water at full load.

Source: Trane (www.trane.com)