AERO® Semi-Custom Central Station Air Handler 39M: Filter Maintenance

This annual procedure focuses on different kinds of your equipment's filters and in-track baffles. This will help ensure that your unit performs at it's peak for a long period of time.

AERO® Semi-Custom Central Station Air Handler 39M: Filter Maintenance

This annual procedure focuses on different kinds of your equipment's filters and in-track baffles. This will help ensure that your unit performs at it's peak for a long period of time.

Filters

Air filters should be inspected regularly and changed when dirty. Filter life can vary greatly from one unit to another, depending upon the application and the amount of contaminants in the return and ventilation air entering the air handler. Each job should be evaluated and maintenance schedules established accordingly. At a minimum, the filters should be changed at the beginning of the cooling and heating seasons.

Although not a direct part of the air handler, outdoor air inlet screens and/or grilles that may be present should also be checked regularly and cleaned as necessary. They can easily become plugged with debris, grease, or other contaminants, depending

upon their location. This reduces the availability of ventilation air, which can contribute to indoor air quality problems.

All filter sections use adjustable blank-off plates to close off any airway area not filled with filter media. Check blank-off plates to prevent unfiltered air from bypassing the filters. Blank-off plates must be on door side of unit.

BAG-CARTRIDGE FILTERS

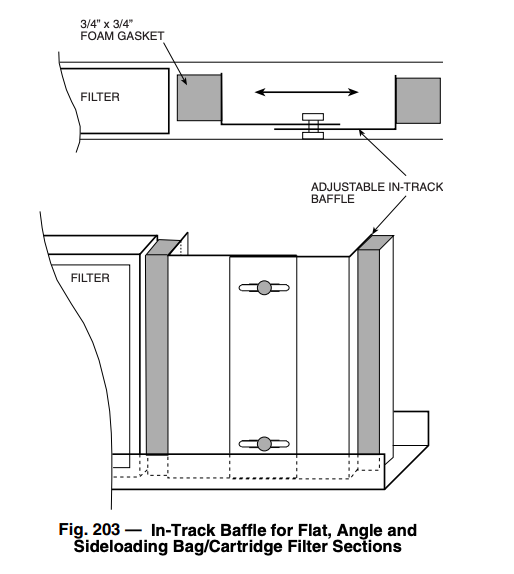

IN-TRACK BAFFLES

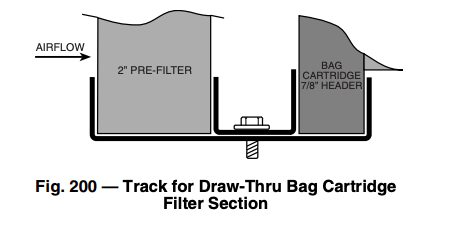

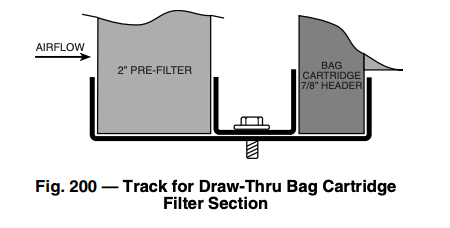

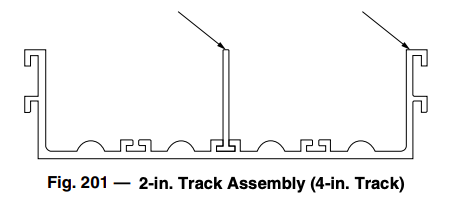

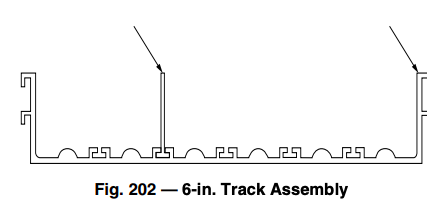

Filter sections are shipped with adjustable in-track baffles. When installed properly as shown in Fig. 201 and 202, the baffles close off empty space in the track preventing air from bypassing the fil- ters.

FLAT FILTERS

ANGLE FILTERS

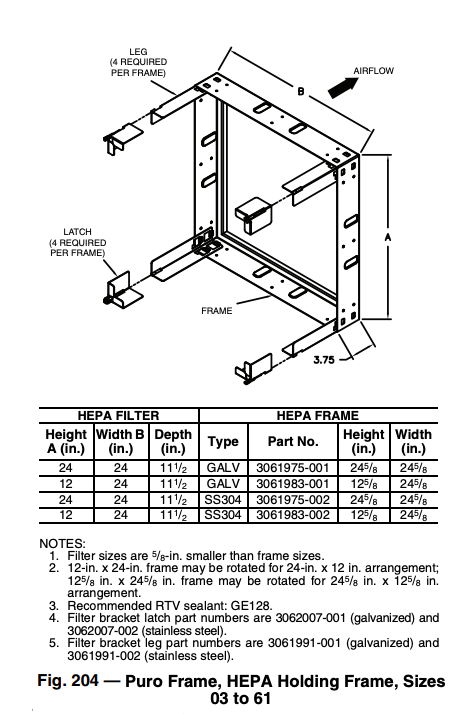

HEPA FILTERS

Filter arrangements are shown in Fig. 206-210.

Source: Carrier (www.shareddocs.com)