HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT 350 Hours/ 2 Months

The HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT 350 Hours/ 2 Months keeps your forklift in prime working condition. Maximize your forklifts capabilities by consistently performing maintenance.

HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT 350 Hours/ 2 Months

The HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT 350 Hours/ 2 Months keeps your forklift in prime working condition. Maximize your forklifts capabilities by consistently performing maintenance.

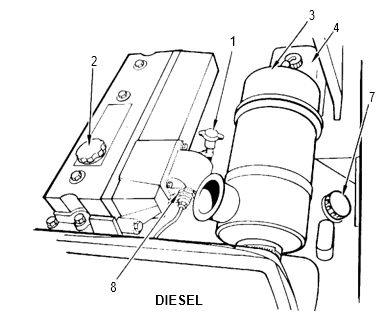

ENGINE OIL, DIESEL Perkins 4.2482

FIGURE 14. ENGINE MAINTENANCE POINTS

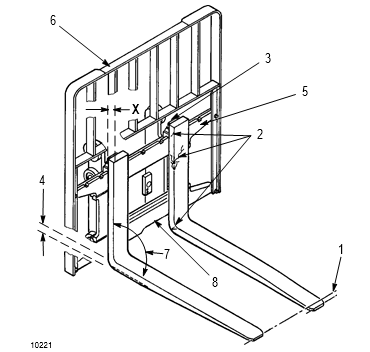

MAST, CARRIAGE, AND LIFT CHAINS

WARNING: Never work under a raised carriage or forks. Lower the carriage or use blocks and chains on the mast weld- ments and carriage so that they can not move. Make sure the moving parts are attached to a part that does not move.

Do not try to correct the alignment of the fork tips by bending the forks or adding shims. Replace damaged forks.

Never repair damaged forks by heating or welding. Forks are made of special steel using special procedures. Replace damaged forks.

FIGURE 21. CHECK THE FORKS

FORK TIP ALIGNMENT

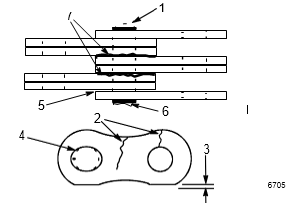

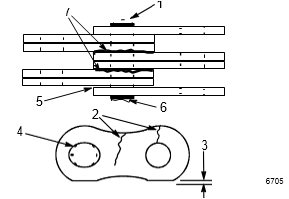

FIGURE 22. CHECK THE LIFT CHAINS

FORKS

FIGURE 22. CHECK THE LIFT CHAINS

AIR FILTER

WARNING: Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all person- nel. Wear protective goggles or a face shield to prevent injury to the eyes.

Adjust as Required

Clean

Check Torque

WHEEL NUTS DRIVE WHEELS

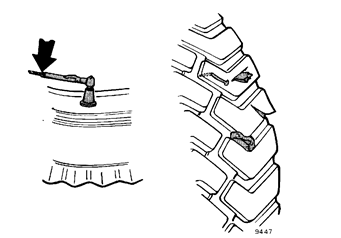

FIGURE 17. CHECK THE TIRES

Check all wheel nuts after 2 to 5 hours of operation:

Source: Hyster