JUNGHEINRICH EFG 320 Electric Forklifts Truck 50 Hours/ Weekly

The JUNGHEINRICH EFG 320 Electric Forklifts Truck 50 Hours/ Weekly inspects all components of the forklift. Ensure that all measures are correctly implemented. From the maintenance to the disposal of batteries.

JUNGHEINRICH EFG 320 Electric Forklifts Truck 50 Hours/ Weekly

The JUNGHEINRICH EFG 320 Electric Forklifts Truck 50 Hours/ Weekly inspects all components of the forklift. Ensure that all measures are correctly implemented. From the maintenance to the disposal of batteries.

Chassis/ superstructure

Daily inspections of the condition and operatability of the safety belt should be carried out by the driver before using the industrial truck. A malfunction can only be detected at an early stage by regular inspection.

Wheels

Steering

Grease all bearings of the steering axle

according to the lubrication schedule with a conventional grease gun at least after 500 hours.

Electric System

Battery

9.2 Check acid density, acid level and cell voltage

Servicing staff

Fire protection measures

Servicing of batteries

Disposal of the battery

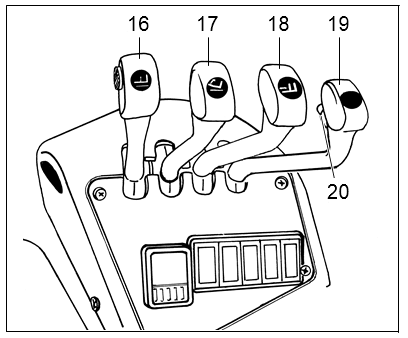

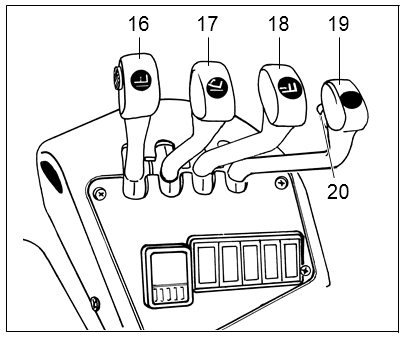

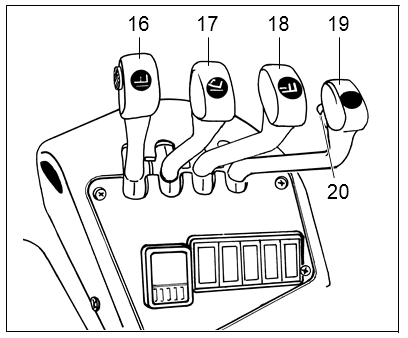

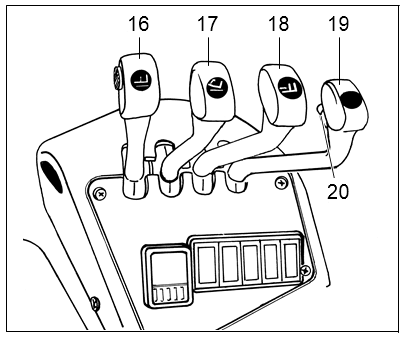

Hoist frame

10.1 Apply grease to running paths and side run areas of idler pulleys in the hoist frame profiles.

10.2 Apply grease to all greasing points of the idler pulleys of the hoist frame and the fork carrier.

10.4 Lubricate lifting chains and chain guides.

Source: Jungheinrich