2015 DOOSAN G20SC-5 Pneumatic Forklift 50-100 Hours/ Monthly

The 2015 DOOSAN G20SC-5 Pneumatic Forklift 50-100 Hours/ Monthly preventive maintenance form offers a complete list of inspection guidelines. This form contributes to a safer working environment and prevent costly lift truck repairs.

2015 DOOSAN G20SC-5 Pneumatic Forklift 50-100 Hours/ Monthly

The 2015 DOOSAN G20SC-5 Pneumatic Forklift 50-100 Hours/ Monthly preventive maintenance form offers a complete list of inspection guidelines. This form contributes to a safer working environment and prevent costly lift truck repairs.

You must read and understand the warnings and instructions contained in the Safety section of this manual, before performing any operation or maintenance procedures.

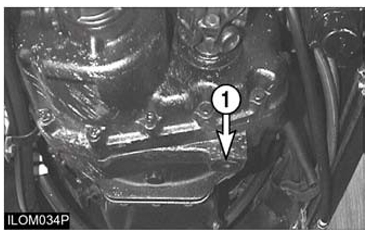

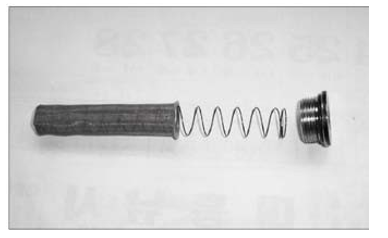

Engine Oil & Filter (Diesel Engine Only) - Change

Diesel Engine Crankcase

The percentage of sulfur in the fuel will affect the engine oil recommendations.

If the fuel has over 0.5% sulfur content, the CD engine oil have a TBN of 20 times the percentage of fuel sulfur (TBN as measured by the ASTM D-2896 method).

Your oil supplier should be able to furnish the correct oils.

WARNING;Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

NOTICE Servicing of the engine oil and oil filter element will largely affect on the engine performance as well as the engine life. Engine oil and filter ele- ment must be changed initially 50 hours.

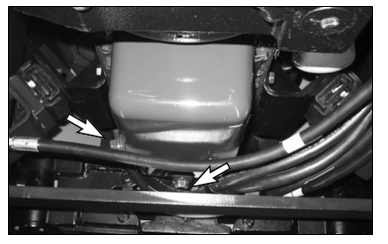

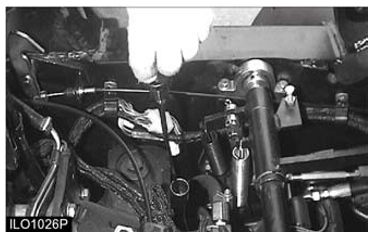

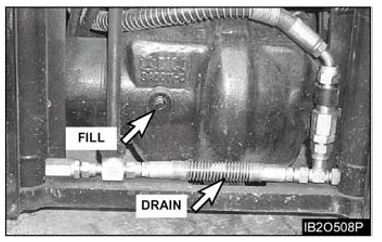

Transmission Oil, Oil Filter & Strainer - Check, Clean, Change

WARNING;Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Park the lift truck level, with the forks lowered, parking brake engaged, direction control lever in NEUTRAL and the engine stopped.

Drive Axle Oil - Change

Parking Brake - Test, Adjust

Parking Brake Testing

NOTICE OSHA requires the parking brake to hold the lift truck, with capacity load, on a 15% grade. Testing requires a test load equal to the capacity of the truck and a 15% grade.

If the maximum grade in the workplace is less than its capacity, use the Parking Brake inspection procedure covered in ‘Inspection from Operator’s Seat, Engine On’ in “Every 10 Service Hours or Daily” section.

WARNING; To prevent personal injury, the operator MUST be ready to use the service brake if the parking brake is not adjusted correctly and the lift truck starts to move.

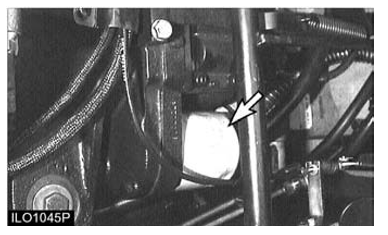

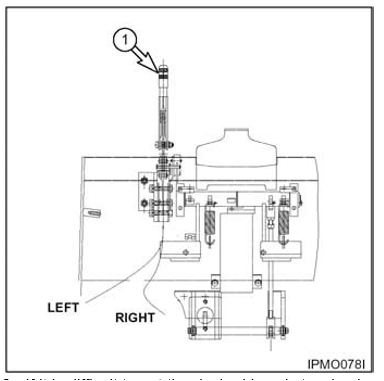

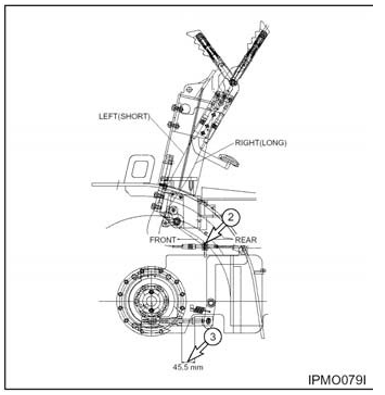

Parking Brake Adjusting

NOTICE Turn the adjustment screw (6) clockwise to tighten. Turning the screw (6) too far counterclockwise could allow parts to fall into the bottom of the transmission. The transmission would than require disassembly to remove the parts.

To Adjust (Oil Cooled Disc Brake Only)

Park the lift truck on the level, with forks lowered, transmission in NEUTRAL, the engine stopped and the wheels securely blocked.

Source: Doosan