WALINGA AGRI-VAC UNIT 6614 DAILY/8 HOURS A DAY MAINTENANCE

WALINGA AGRI-VAC UNIT 6614 DAILY/8 HOURS A DAY MAINTENANCE

Maintenance Safety

Follow good shop practices

5.1 SERVICE

5.1.1 FLUIDS AND LUBRICANTS

Grease:

Use Walinga Blower oil (part# 98-13813-6)

Storing Lubricants:

5.1.2 GREASING

Refer to Section 5.1.1 for recommended grease. Use the Service Record checklist provided to keep a record of all scheduled servicing.

Fig. 5-1 PTO Shaft Lubrication Points.

Fig. 5-2 Drive Belts.

Fig. 5-3 Blower Reservoir Schematics.

Fig. 5-4 Blower Reservoirs (Front)

Fig. 5-5 Blower Reservoirs (Rear)

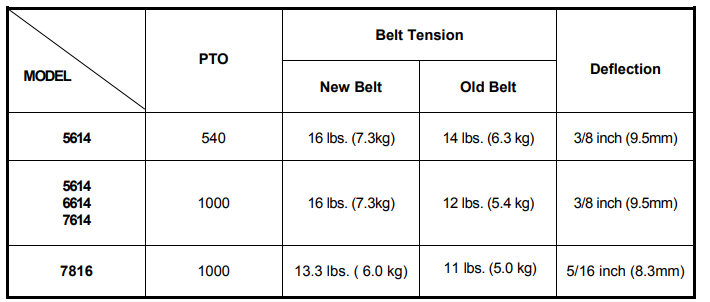

5.2.1 BELT TENSION AND ALIGNMENT

Follow this procedure when checking and adjusting the belt tension and the pulley alignment.

Fig. 5-16 Belt Deflection

Fig. 5-17 Belt Deflection.

Adjusting Tension:

Fig. 5-18 Adjusting Bolts.

Machine is shown with guard remove for illustrative purposes only. Do not operate machine with guard removed.

Pulley Alignment:

Machine is shown with guard removed for illustrative purposes only . Do not operate machine with guard removed.

Fig. 5-19 Pulleys

Fig. 5-20 Misalignment

Fig. 5-21 Adjusting Bolts At Input Shaft.

Machine is shown with guard removed for illustrative purposes only . Do not operate machine with guard removed.

Fig. 5-22 Adjusting Anchor Bolts At Bearing Housing Assembly

5.2.2 BLOWER OIL CHANGING AND BREATHER CLEANING

The gears that drive and time the blower lobes run in an oil bath for lubrication. Maintaining the correct level in the reservoirs and changing every 100 hours will insure proper lubrication.

When maintaining the blower, follow this procedure:

Fig. 5-23 Blower Schematics.

Checking Oil Level:

IMPORTANT Check the oil level only when the oil is cold and the machine is level.

Fig. 5-24 Blower (Rear)

IMPORTANT: It is necessary to maintain the recommended oil level in the reservoir. A low level causes heating from lack of lubrication and rapid gear and bearing wear. Too much oil causes heating from oil churning and can cause seal and breather leaks.

Fig. 5-25 Blower (Front)

5.2.2 BLOWER OIL CHANGING AND BREATHER CLEANING

Changing Oil:

IMPORTANT : Condensation forms and collects inside the reservoirs during machine operation. Changing oil removes this water and prevents it from damaging the gears and bearings

Fig. 5-26 Blower Schematics.

Cleaning Breathers:

Fig. 5-27 Breathers

Source: Walinga