AAON RQ Series Indirect Fired Heat Pump Yearly Maintenance

The AAON RQ Series Indirect Fired Heat Pump Yearly Maintenance is a standard procedure that checks the operation quality of the machines components. Be sure to follow the safety steps provided to avoid any accidents.

AAON RQ Series Indirect Fired Heat Pump Yearly Maintenance

The AAON RQ Series Indirect Fired Heat Pump Yearly Maintenance is a standard procedure that checks the operation quality of the machines components. Be sure to follow the safety steps provided to avoid any accidents.

At least once each year, a trained, qualified service technician should check out the unit. Fans, evaporator coils, and filters should be inspected at least monthly.

Gas Heating

WARNING! Once a year, before the unit is in operation for the heating season, a qualified service technician should inspect all flue product carrying areas of the furnace and main burners for continued safe operation.

DANGER! LEAK CHECK GAS PIPE The gas pipe in the unit should be checked for leaks before startup. Leak checking is the responsibility of the installing contractor. All connections should be checked for leaks annually after installation. Failure to leak che

Gas Heat Exchanger Removal

WARNING! Electric shock hazard. Shut off all electrical power to the unit to avoid shock hazard or injury from rotating parts.

DANGER! LEAK CHECK GAS PIPE The gas pipe in the unit should be checked for leaks before startup. Leak checking is the responsibility of the installing contractor. All connections should be checked for leaks annually after installation. Failure to leak che

Removal

Reinstallation

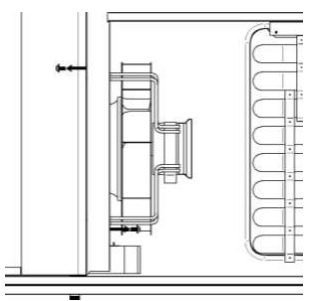

Figure 29 - Gas Heat Exchanger

DX Cooling

Condenser Fan

WARNING! Electric shock hazard. Shut off all electrical power to the unit to avoid shock hazard or injury from rotating parts.

WARNING! Improper installation, adjustment, alteration, service, or maintenance can cause property damage, personal injury, or loss of life. Startup and service must be performed by a Factory Trained Service Technician.

Removal

Figure 30 - Removal of a Condenser Fan Assembly

Reinstallation

Condensate Drain Pans

Evaporator Coil

WARNING! Electric shock hazard. Shut off all electrical power to the unit to avoid shock hazard or injury from rotating parts.

Removal

Figure 31 - Evaporator Coil Access

Reinstallation

E-Coated Coil Cleaning

WARNING! Electric shock hazard. Shut off all electrical power to the unit to avoid shock hazard or injury from rotating parts.

CAUTION! High velocity water from a pressure washer or compressed air should only be used at a very low pressure to prevent fin and/or coil damages. The force of the water or air jet may bend the fin edges and increase airside pressure drop. Reduced unit

CAUTION! Harsh chemicals, household bleach, or acid cleaners should not be used to clean outdoor or indoor e-coated coils. These cleaners can be very difficult to rinse out of the coil and can accelerate corrosion and attack the e-coating. If there is dir

Recommended Coil Cleaner

The following cleaning agent, assuming it is used in accordance with the manufacturer’s directions on the container for proper mixing and cleaning, has been approved for use on e-coated coils to remove

Enviro-Coil Concentrate, Part Number HEC01.

Recommended Chloride Remover

Remove Barrier

Apply CHLOR*RID DTS

Rinse

Microchannel Coil Cleaning

Allowed Chemical Cleaners and Procedures

WARNING! Electric shock hazard. Shut off all electrical power to the unit to avoid shock hazard or injury from rotating parts.

Simple Green

Simple Green is available from AAON Parts and Supply (Part# T10701) and is biodegradable with a neutral 6.5 pH. Recommendation is to use it at a 4 to 1 mix. Use the following procedure.

Water Flush

This procedure can be used when the only material to cause the coil to need cleaning is debris from plant material that has impinged the coil face.

CAUTION! Use pressurized clean water, with pressure not to exceed 140 psi. Nozzle should be 6” and 80° to 90° from coil face. Failure to do so could result in coil damage.

Application Examples

Other Coil Cleaners

Roofing

Supply Fan

WARNING! Electric shock hazard. Shut off all electrical power to the unit to avoid shock hazard or injury from rotating parts.

CAUTION! Blower wheels and bands must be inspected for excessive dust build up periodically and cleaned if required. Excessive dust build up on blower wheels may cause an unbalanced state; leading to vibration and/or component failure. Damages due to exce

Factory Lubrication

Note: Bearing lubrication only applies to belt driven fan motors such as the energy recovery wheel power exhaust fan motor.

Recommended greases are:

Removal

Figure 32 - 2-6 ton Supply Fan

Slide blower assembly

out of unit through blower access opening (see Figure 34).

Figure 34 - RQ Supply Fan Removal Slide

Phase and Brownout Protection Module

DPM Setup Procedure

Recommended Default Set-up

Source: Aaon