2019 CLARK S30L IC Pneumatic 50-250 hours Daily Maintenance

The 2019 CLARK S30L IC Pneumatic 50-250 hours Daily Maintenance form helps you check your truck for obvious damage and leaks. The form gives you a list of what and which components to check and what to look out for. Ensure your equipment gives quality performance by doing this preventive maintenance daily.

2019 CLARK S30L IC Pneumatic 50-250 hours Daily Maintenance

The 2019 CLARK S30L IC Pneumatic 50-250 hours Daily Maintenance form helps you check your truck for obvious damage and leaks. The form gives you a list of what and which components to check and what to look out for. Ensure your equipment gives quality performance by doing this preventive maintenance daily.

Check truck for obvious damage and leaks.

First, perform a visual inspection of the truck and its major components:

Check fuel system for leaks, etc

When changing liquefied petroleum gas (LPG), tanks follow these basic rules:

Check capacity, warning plates and decals.

Check condition of tires and wheels. Remove embedded objects. Check air pressure.

Disassembling the Split Rim Wheel

Check for missing or loose wheel lugs nuts.

Check engine oil level.

It is recommended to:

Check engine coolant level (radiator and recovery tank)

check the coolant system for leaks.

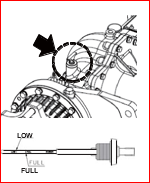

Check trans axle fluid level

Check hydraulic sump oil level.

Check warning lights and hour meter.

Hour Meter

Indicator Lights

Check overhead guard condition and bolts.

Be sure that the driver's overhead guard and any safety devices are in :

Check horn operation and other warning devices.

Check steering operation.

Check directional and speed controls operation.

Be sure that the travel area is clear in front of the truck.

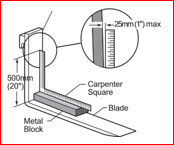

Check upright, lift chains and fasteners.

Upright and Tilt Cylinder Lubrication

Lift Chains

Critical items include:

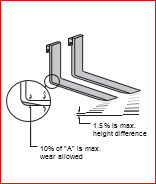

Check carriage or attachments and forks.

Check carriage or attachments and forks.

If the fork blade at the heel is worn down by more than 10%, the load capacity is reduced and the fork must be replaced.

Source: Clark