Ski Lift Inspection Requirements, Frequency, and Methods - Annual

Ski resorts are required to follow state inspection requirements and those mandated by their insurance companies.

Ski Lift Inspection Requirements, Frequency, and Methods - Annual

Ski resorts are required to follow state inspection requirements and those mandated by their insurance companies.

Reference document: https://catsr.vse.gmu.edu/SYST490/495_2018_SkiLift/SkiLift_Final_Report.pdf - Page 10 Section 1.5

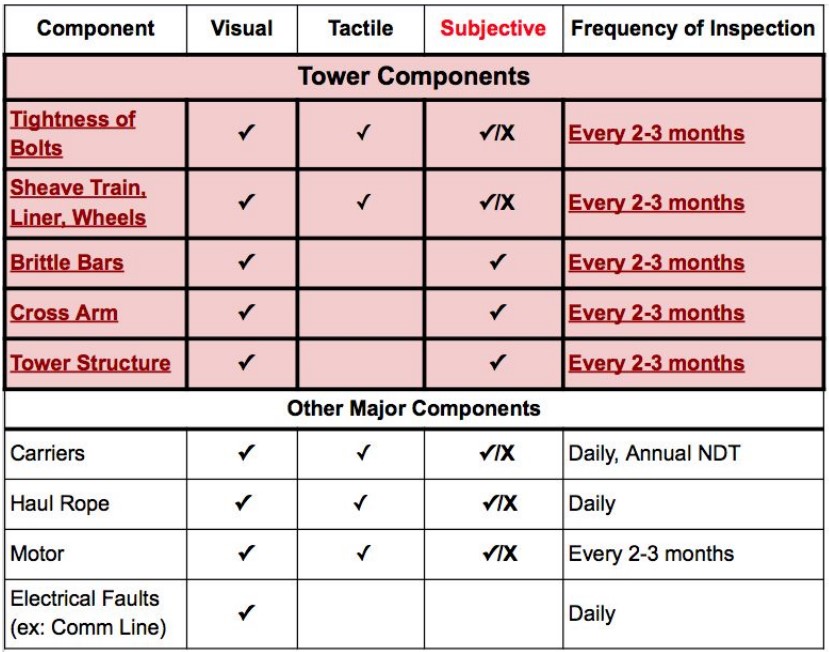

In terms of inspection difficulty, 82% of the ski lift components listed below can be visually inspected without removing any shields. The communication line and the ski lift tower base require special inspection procedures. The comm line is held in a watertight enclosure that is checked every 3-5 years. However, electric faults in the comm line are indicated in the terminal’s control system which is checked daily. The ski lift tower base is examined for cracks using X-ray imaging every 5-10 years at Bryce

The scope of the system’s capabilities exclude components that can be inspected from fault indications or in the terminal, components that require the removal of covers, or tactile inspections. The red underlined components in the table below indicate which components are within scope for visual inspection. Gaps in system capabilities for the tactile inspection of these components can be performed during regular tower maintenance, such as greasing.

Table 4: Visual versus Tactile Inspections

For comparison, the current inspection procedures for Bryce Resort and system capabilities are summarized below.

Sheave Train

Current Inspection Method

Climb up tower and check for misalignment or cracks visually

System Capabilities

Sheave Wheels/Liner

Current Inspection Method

Climb up tower and check for misalignment, debris/ice, and liner wear visually

System Capabilities

Brittle Bars

Current Inspection Method

Climb up tower and check for debris/ice, corrosion

Check for electrical fault in terminal

System Capabilities

Connections and Welds

Current Inspection Method

Climb up tower and check for cracks visually

Physically check tightness of bolts

System Capabilities

Cross Arm

Current Inspection Method

Climb up tower and check for cracks, corrosion

System Capabilities

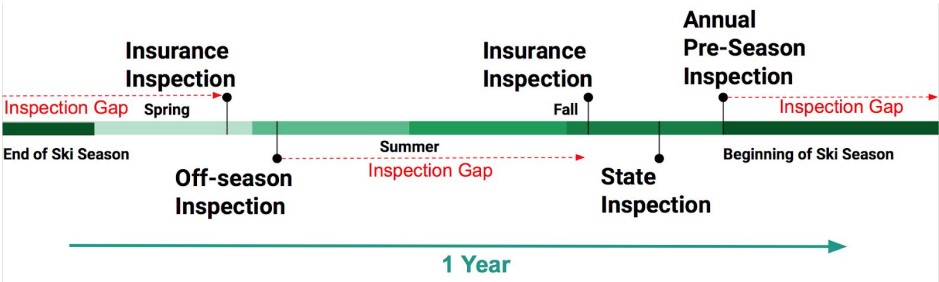

Due to the safety-critical structural support that ski lift towers provide and the frequency of component failures related to the tower, the tower is the most crucial part of ski lift inspections. The difficulty and risk associated with climbing the tower limit the frequency at which ski lift towers can be inspected. In general, there are five inspections performed annually for ski lift tower components, which have gaps of two to three months between them in which component failures can go unnoticed. The ti

Figure 6: A yearly timeline for full-system inspections performed at Bryce Resort (tower inspections).

Source: MaintainX (Community Member)