JUNGHEINRICH ESC 316 Reach Truck FORMS (Daily Maintenance)

The JUNGHEINRICH ESC 316 Reach Truck FORMS (Daily Maintenance) maintains your stacker in prime working condition. Keep your Reach Truck in the best quality by regularly performing maintenance and inspections.

JUNGHEINRICH ESC 316 Reach Truck FORMS (Daily Maintenance)

The JUNGHEINRICH ESC 316 Reach Truck FORMS (Daily Maintenance) maintains your stacker in prime working condition. Keep your Reach Truck in the best quality by regularly performing maintenance and inspections.

3 Preparing the Truck for Operation

WARNING! Risk of accident due to damage to or other defects in the truck and optional features

If damage or other truck or attachment (optional equipment) defects are discovered during the following checks, the truck must be taken out of service until it has been repaired.

Procedure

3.2 Preparing the truck for operation

Switching on the truck

Procedure

The truck is ready for operation.

3.3 Checks and operations to be carried out when the truck is operational

WARNING!Risk of accident due to damage to or other defects in the truck and optional features

If damage or other truck or attachment (optional equipment) defects are discovered during the following checks, the truck must be taken out of service until it has been repaired.

Procedure

Test the effectiveness of the brakes, see "Brakes" on page 66.

WARNING!Accident risk while braking

The truck’s braking response depends largely on the floor condition and the type of surface. The truck’s braking distance increases when the ground is wet or dirty.

The truck can brake in two ways:

CAUTION!

Braking with the service brake

Procedure

The truck decelerates regeneratively at the maximum rate until it comes to a halt. The parking brake then applies.

Regenerative braking

Procedure

The Multi-Pilot reverts to the neutral position. The truck brakes regeneratively to a halt. The parking brake then applies.

The brake force can be set by the manufacturer’s customer service department.

Test the steering, see "Steering" on page 65.

Procedure

Test the hydraulic system, see "Load handler raise/lower" on page 68.

WARNING! Accident risk when lifting and lowering

Other people can be injured in the truck's hazardous area. The hazardous area is defined as the area in which people are at risk from the movement of the truck including the load handler, etc.

This also includes areas which can be reached by falling loads, operating equipment, etc. Apart from the driver (in the normal operating position) there should be no other people in the truck's hazardous area.

Test travel operations, see "Travel" on page 63.

WARNING!Collision hazard when operating the truck

Collisions with personnel and equipment can result if the truck is operated with open panels.

Procedure

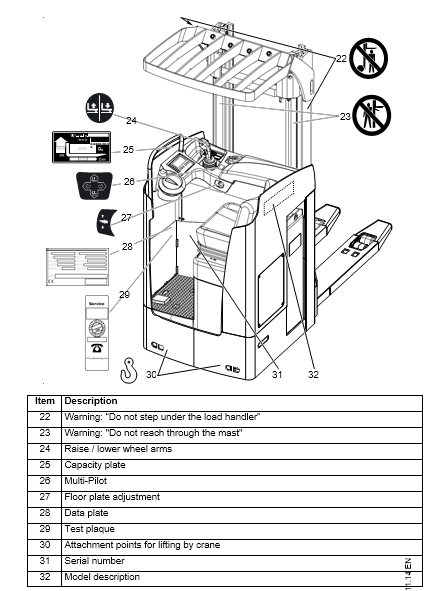

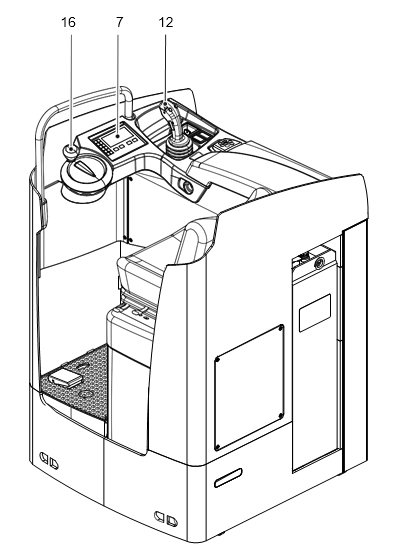

Test the controls and displays and check for damage, see "Displays and Controls" on page 45.

Control/Display

3.4 Parking the truck securely

WARNING!An unsecured truck can cause accidents

Parking the truck on an incline, without the brakes applied or with a raised load or load handler is dangerous and is strictly prohibited.

Parking the truck securely

Procedure

Switch off the truck, to do this:

The truck is parked.

3.5 Entry and exit

Requirements

Procedure

Always enter and exit the truck facing the load direction.

CAUTION!No more than one person may operate the truck at a time.

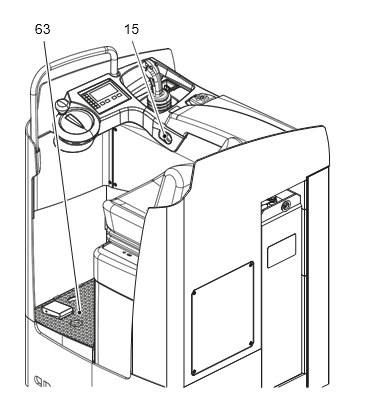

3.6 Adjusting the floor plate height

Procedure

3.7 Adjusting the driver’s seat

CAUTION! An unsecured driver's seat can cause injury

An unsecured driver's seat can slide out of its guide during travel, resulting in accidents.

Adjusting the driver’s seat

Procedure

The driver's seat is now set in the correct position for the controls.

Source: Jungheinrich