Skipper Monthly PM

If your equipment is well maintained, it's less likely to breakdown, which leads to increased uptime, more working hours for the equipment, fewer repair costs, and therefore increased revenue.

Skipper Monthly PM

If your equipment is well maintained, it's less likely to breakdown, which leads to increased uptime, more working hours for the equipment, fewer repair costs, and therefore increased revenue.

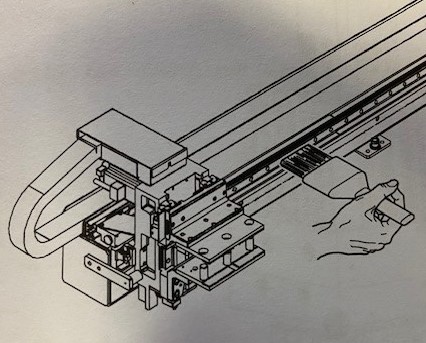

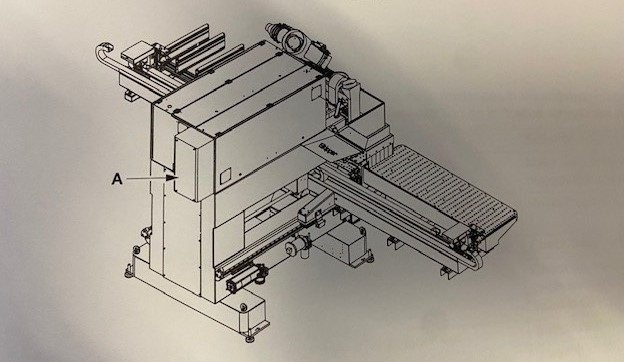

Cleaning the guides and racks

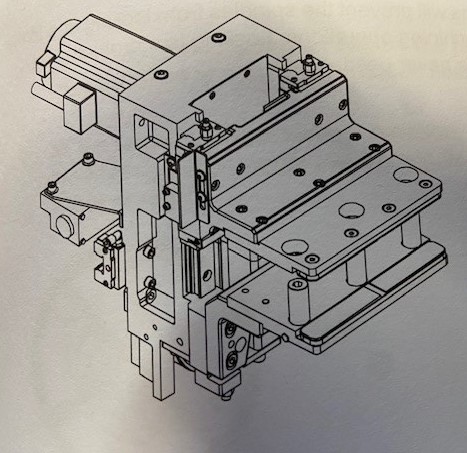

Cleaning the clamps

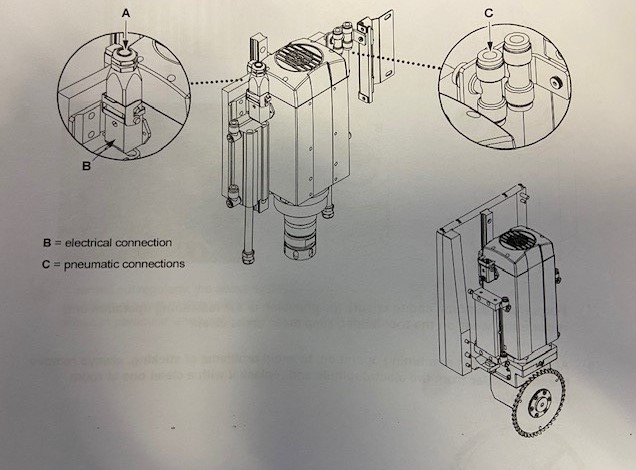

Checking the pneumatic devices

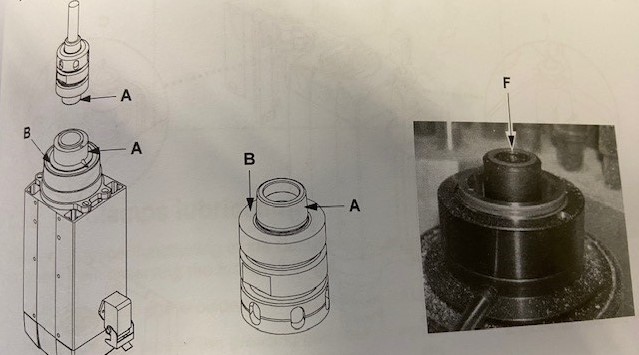

Checking and cleaning the electrospindle and the tool holder

Checking the electrospindle connections

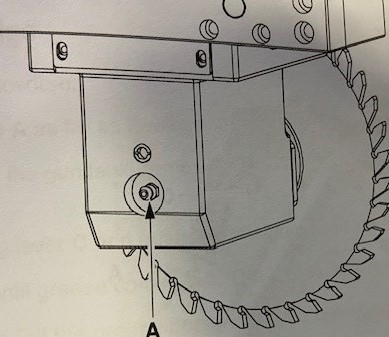

Lubricating the blade unit

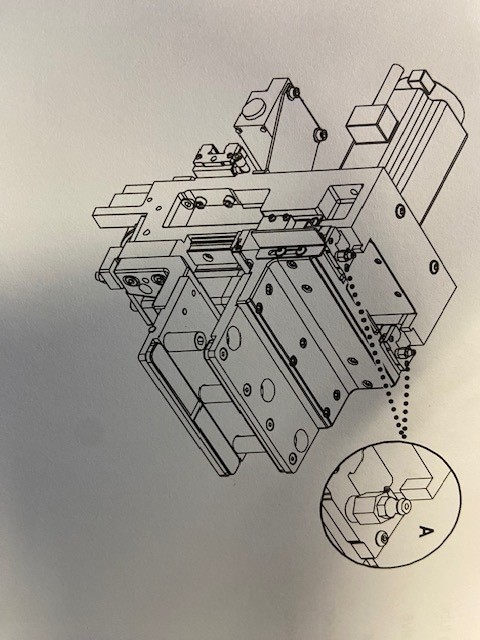

Clamp lubrication

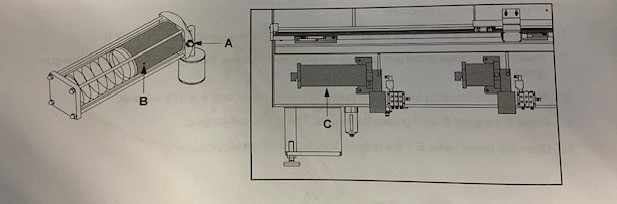

Topping up the automatic lubrication system of the main machine axes

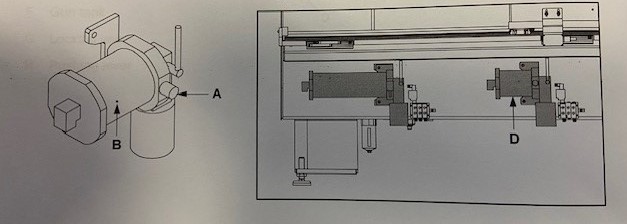

Topping up the automatic lubrication system of the boring units

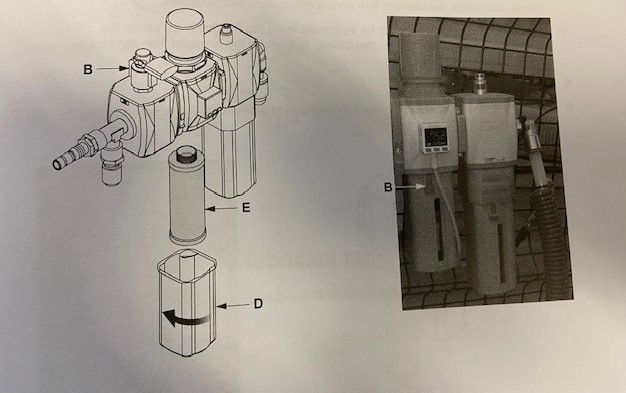

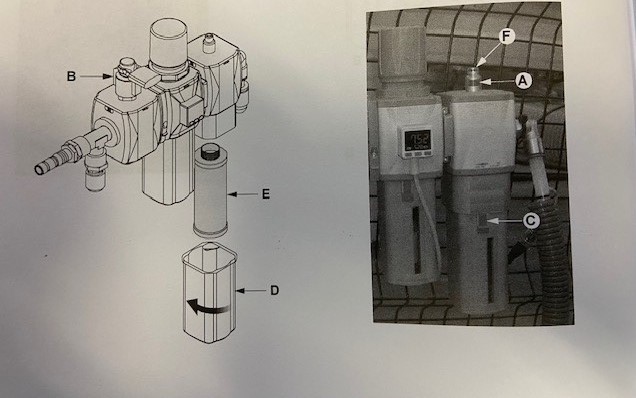

Draining the condensate from the FR unit

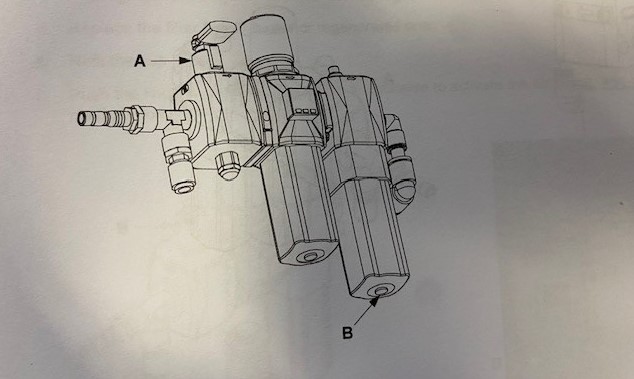

Adjusting the air pressure. The pressure level is adjusted during the test phase at 7-7.5 bar. if the value is different that the one set, check the reason of the pressure drop or increase and then if necessary adjust.

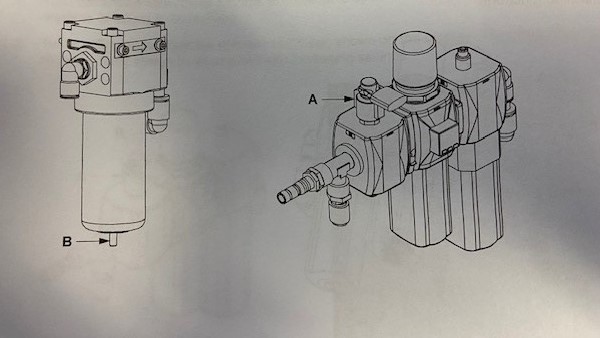

Draining the oil from the oil separator filter

Draining the condensate from the dryer

Cleaning and replacing the FR unit filter

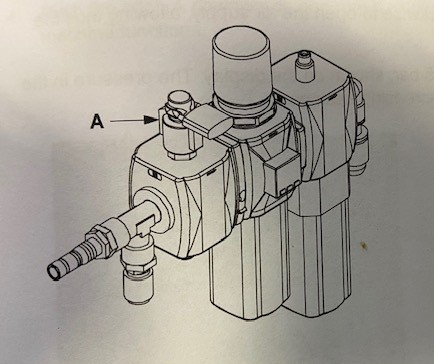

Replacing the oil separator filter. When the filter cartridge needs to be replaced, the service indicator A changes from green to red. Following the procedure below to replace the cartridge.

Cleaning the air condition

Source: Laminate Technologies-Tiffin, OH (Community Member)