Sennebogen Blank Inspection Form

Maintenance inspections can identify minor issues before they turn into costly repairs. Inspections ensure machines are working correctly and helps prevent equipment downtime. Just about every plant or facility must conduct regular inspections as part of its overall maintenance program.

Sennebogen Blank Inspection Form

Maintenance inspections can identify minor issues before they turn into costly repairs. Inspections ensure machines are working correctly and helps prevent equipment downtime. Just about every plant or facility must conduct regular inspections as part of its overall maintenance program.

Customer Information

Contact Person

Title

Street

City

State

code

Country

Office Phone

Cell Phone

Company

Dealer Information

Location

Contact Person

Company

Machine Information

Main Electric Panel Hour Meter Reading (electric mach.)

Analog Hour Meter Reading (diesel machine)

Machine Serial No

SENNEBOGEN Inspector

Signature

Click here to sign

Date

Name (please print)

Pre-Inspection

Pressure washed

upper carriage

lower carriage

boom

stick

Man lift provided

Safety

Fire Extinguishers

cab/charged

tool box undercarriage/charged (if equipped)

upper carriage charged (if equipped)

Comments

Lights

working lights (if equipped)

beacon light (if equipped)

brake lights

flashers

indicator lights

Comments

Limitation

boom down operable (if equipped)

boom up operable (if equipped)

stick in operable (if equipped)

stick out operable (if equipped)

Comments

Lights Steps, ladders & handrails Fire Extinguishers

under carriage steps ( if equipped)

access ladder for upper carriage

steps inside pylon (if equipped)

pedestal access ladder (if equipped)

r/h hand rails ( if equipped)

l/h hand rails ( if equipped)

Comments

Cab exterior

catwalk ( if equipped)

cab riser and hoses

wiper arms / blades

travel alarm

Comments

windows / skylight and guards

Cab interior

pedals

switches / buttons

indicators / icons

safety lever

horn

air unit

cab filter(s)

Comments

joysticks

Fluid levels

hydraulic oil

swing motor oil

swing bearing lube

coolant

autogreaser

engine oil

Engine

starting

engine mounts

air filters

fuel lines

water separator

a/c compressor

pre heater

Comments

performance

Hydraulic system

Hydraulic system

performance

main pump

gear pumps

oil cooler

hoses

radiator fan

control valve

pre heater ( if equipped)

hydroclean

cut off valve

oil - clear / dirty looking

breather

Comments

Hydraulic pressures

stand-by

pressure cut off

swing left

swing right

grapple open

grapple close

pilot

Comments

Electrical system

battery cables

battery cover

starter / alternator cables

alternator

electrical slip ring (if equipped)

Comments

batteries

Swing system

lubrication

swing bearing

swing gear

swing bearing deflection (max 3mm)

actual reading

Meter name

Unit

Comments

performance

Magnet system

generator

controller

pulley / belt

contact tips

Comments

performance

Lubrication system

lower carriage grease lines

upper carriage grease lines

boom and stick grease lines

Comments

grease pump

Undercarriage

Axles & drive system

performance

transmission

drive shafts

travel motor

travel brake

parking brake

osc. cylinders

osc. cylinders unlock

differential

axle pin lock

brake hoses

grease lines

Comments

Tires / rims

tires

rims

lug nuts

intermediate rings

Comments

Outriggers

performance

cylinders

cylinder guards

individual control

Comments

Tracks

track pads

track links

track rollers / guides

track hoses

Comments

Boom

safety valves

pins

hoses

lubrication

Comments

cylinders

Stick

safety valves

pins

hoses

lubrication

magnet plug

tubing

Comments

cylinders

Counterweight (Visual only)

All stop bolts against rear of counterweight and undamaged

Bottom stop bolts tight and undamaged

Upper right and left stopper plates against side of counterweight

All jamb nuts tight

Center bolt tight and undamaged

Has counterweight been struck

Are factory shim plates installed

Comments

Counterweight against stop on upper carriage

Attachment

Manufacturer

Model

Volume / Size

scrap grapple

scrap maggrapple

log grapple

contractor grapple

clamshell

magnet

shims tight

pins

cylinders

hoses

speed

Comments

Cab / Compartment Cleanliness

engine compartment

pump compartment

sound insulation / exhaust insulation

upper / lower carriage

Comments

operator cab

Structural, stick

stick cylinder pin bosses (2)

stick tip (3)

right side plate

left side plate

top plate

bottom plate

Comments

heel section (1)

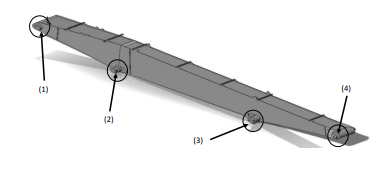

Structural, boom

boom cylinder pin bosses (2)

lower stick cylinder pin bosses (3)

boom tip (4)

right side plate

left top plate

top plate

bottom plate

Comments

heel section (1)

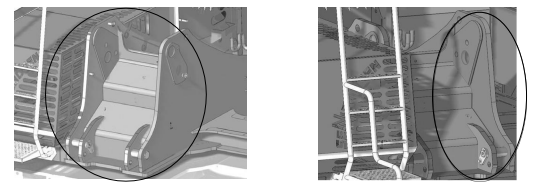

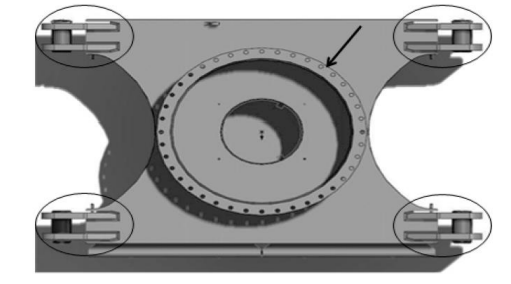

Structural upper carriage

boom mount plates to main frame

reinforcement plates

side plate welds to main frame

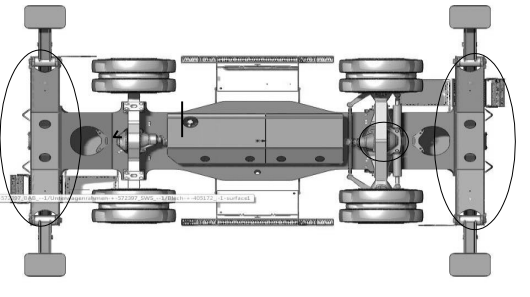

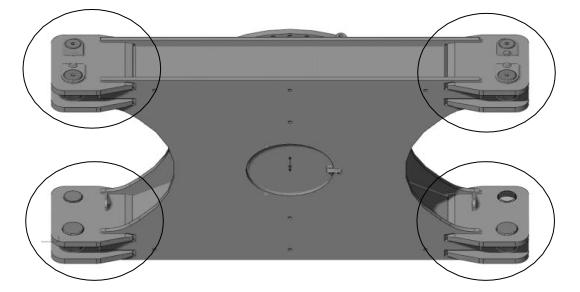

Structural - under carriage (mobile- top view )

swing bearing flange ring weldment weld

top plate welds

stabilizer box welds

Structural - under carriage (mobile- side view)

side plate welds

reinforcement plate welds

stabilizer box welds

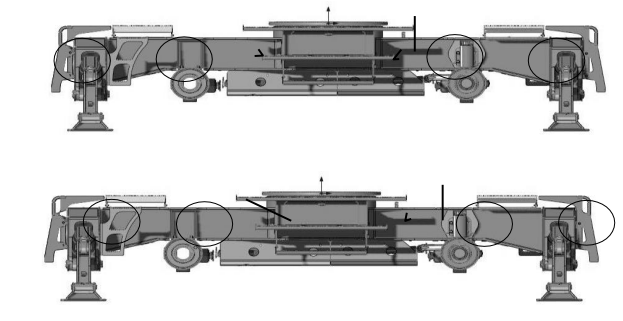

Structural - under carriage ( crawler-top view)

side frame weldment welds

swing bearing flange weldment ring

Structural - under carriage ( crawler-bottom view)

side frame weldment plates to bottom plates

side frame weldment plates

Source: MaintainX (Community Member)