2015 HYSTER J35XNT DOWN Wheeled Electric Forklift 500 Hours /3 Months

The 2015 HYSTER J35XNT DOWN Wheeled Electric Forklift 500 Hours /3 Months inspects all components of your forklift to ensure that it is kept in quality working condition.

2015 HYSTER J35XNT DOWN Wheeled Electric Forklift 500 Hours /3 Months

The 2015 HYSTER J35XNT DOWN Wheeled Electric Forklift 500 Hours /3 Months inspects all components of your forklift to ensure that it is kept in quality working condition.

Drive Tire and Wheel Assemblies

Pedals, Seat Assembly, Hood, Hinges, and Hood Latch

Use Multipurpose Grease

Inspect for:

Breather Cap

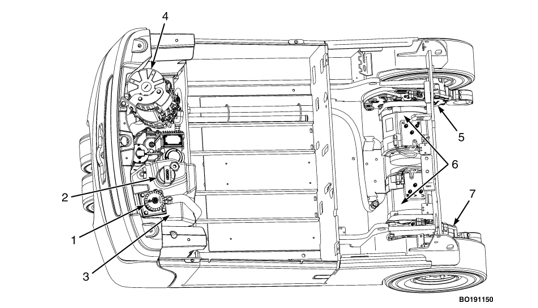

Figure 3. Motor Locations, Lift Trucks Manufactured

Manual Override Handle

Use Multipurpose Grease.

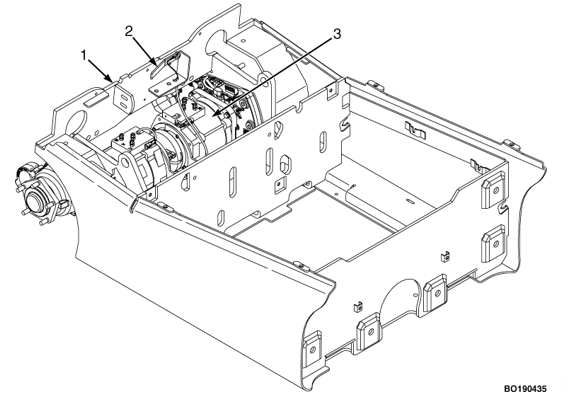

Figure 22. Automatic Parking Brake Override Handle

Silicone Spray Lubricant. Hyster P/N 328388.

Master Cylinder Reservoir

Visually check the :

Use Multipurpose Grease.

Mast Mounting Caps crews

Inspection of Mast, Carriage, Header Hoses, Lift Chains, and Attachments

Figure 32. Mast Lubrication

NOTE: MAST IS DIFFERENT, BUT LUBRICATION AREAS ARE THE SAME.

Lift Chains

Visually inspect hoses/fittings for

hydraulic leaks

hose covers for cuts

cracks

exposed reinforcement

defective/broken clamping devices or sheaves

proper tracking during operation

NOTE: Chain anchor pins MUST be replaced any time chains are replaced.

Figure 33. Check the Lift Chains

Adjustments or replacement of the lift chains must be done by authorized personnel.

Header Hoses, Hose Fittings, and Clamps

Inspect for :

Fork Guides and Pins

WARNING: DO NOT try to move a fork without a lifting device. The forks can weigh 45 to 115 kg (99 to 254 lb).

Figure 31. Fork Lock Pin Assembly

Transaxle

Direction and Speed Control Pedals (Use Silicone Spray Lubri- cant. Hyster P/N 328388)

Source: Hyster