Lavatec Dryer Annual PM 443

Routine inspections are your way of ensuring that you’re able to detect any issues before they become full-blown crises. Regular inspections ensure that your compressed air dryer is keeping up with the stringent standards required in these sectors.

Lavatec Dryer Annual PM 443

Routine inspections are your way of ensuring that you’re able to detect any issues before they become full-blown crises. Regular inspections ensure that your compressed air dryer is keeping up with the stringent standards required in these sectors.

*** LOTO Confirmation Statement - DO NOT EDIT/REMOVE ***-

All hazardous energy has been isolated using LOTO procedures?

All potential stored or residual energy has been relieved, disconnected, restrained, lowered, and/or otherwise rendered safe?

Lock Out Tag Out

LOTO Performed

Food Safety Pre-Check

ENERGY CONTROL PROGRAM - Utilize the Cintas ENERGY CONTROL PROGRAM Checklist when applying LOTO.

Dryer Monthly PM - Perform dryer monthly PM in preparation for the annual PM. Manually generate this PM in eMaint if necessary.

Burner Inspection and Safety Checks - Verify burner firing rate. Perform gas valve leakage test. Inspect/test gas train safeties. Inspect burner and diffuser plate integrity. Check diffuser plate and wings for chipping, cracking and debris build-up. Orifices/ports should be uniform and clean of debris. Insert outside contractor report.

Add or drag pictures

Change Gearbox Oil - Drain and replace oil in both drive shaft gearboxes using ISO 680 gear oil.

Moisture Inhibitor - Verify that a moisture inhibitor/desiccant is present and in good condition in the electrical cabinet.

Clean Up - Clean up all tools, parts, and debris from the work area.

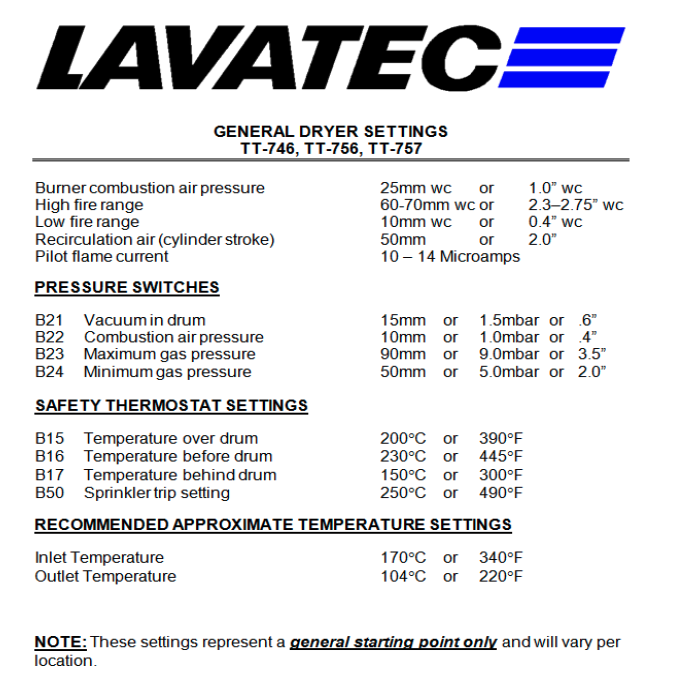

All Lavatec OEM Switch and pressure settings are included below

Food Safety Post-Check

Source: 443 Fox Valley WI (Community Member)