Doosan D33S-5 Pneumatic Forklift 500 Hours /3 Months

The Doosan D33S-5 Pneumatic Forklift 500 Hours /3 Months ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Doosan D33S-5 Pneumatic Forklift 500 Hours /3 Months

The Doosan D33S-5 Pneumatic Forklift 500 Hours /3 Months ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

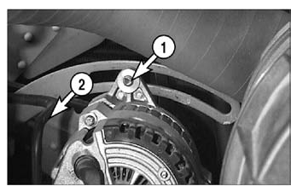

Belts - Check, Adjust

NOTICE Failure to loosen the alternator mounting bolt (2) will cause excessive stress and break the alternator mounting ear.

Mast Hinge Pin – Lubricate

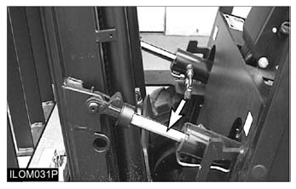

Tilt Cylinders - Check, Adjust, Lubricate

Chassis Pivot Eye bolts-Lubricate

Mast Pivot Eyes-Lubricate

Cylinder Rod Extension-Adjust

NOTE: The following description is for forward tilt. For cylinder rod back tilt, the collar should be stationary by the tilt eye. If it is not, the O-ring inside the collar may need to be replaced. To adjust back tilt, spacers must be added or removed.

Crosshead Rollers - Inspect

Check Operation

Operate the mast through a lift cycle. Watch the chains move over the crosshead rollers. Make sure the chain is tracking over the rollers properly.

Transmission Oil Filter – Change

WARNING:Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Park the lift truck level, with the forks lowered, parking brake engaged, direction control lever in NEUTRAL and the engine stopped.

Overhead Guard – Inspect

Drive Axle Oil & Strainer - Change, Clean

Park the lift truck level, with the forks lowered, parking brake engaged, transmission in NEUTRAL and engine stopped.

Steer Suspension – Inspect

Parking Brake - Test, Adjust

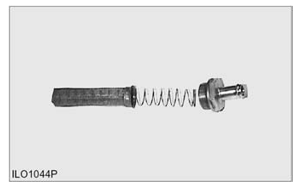

Inching & Braking Control Shaft - Lubricate

Horn and Lights (If Equipped) - Check

Source: Doosan