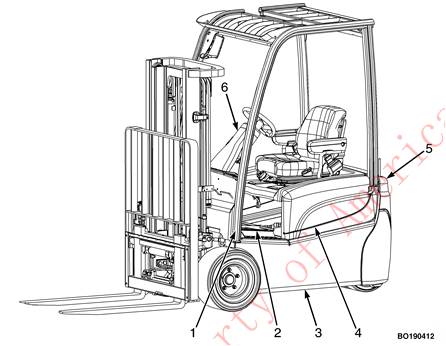

2015 HYSTER J35XNT Wheeled Electric Forklift Daily Maintenance Check

The 2015 HYSTER J35XNT Wheeled Electric Forklift Daily Maintenance Check inspects all components of your forklift to ensure that it is kept in quality working condition.

2015 HYSTER J35XNT Wheeled Electric Forklift Daily Maintenance Check

The 2015 HYSTER J35XNT Wheeled Electric Forklift Daily Maintenance Check inspects all components of your forklift to ensure that it is kept in quality working condition.

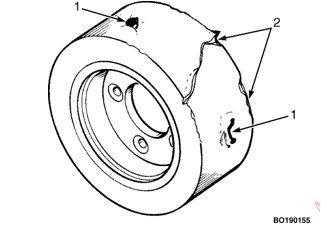

Drive Tire and Wheel Assemblies

Tire and Wheel

Figure 25. Tire Check

Safety labels are installed on the lift truck to provide information about possible hazards. It is important that all safety labels are installed on the lift truck and can be read.

Check Operation. Repair as Required.

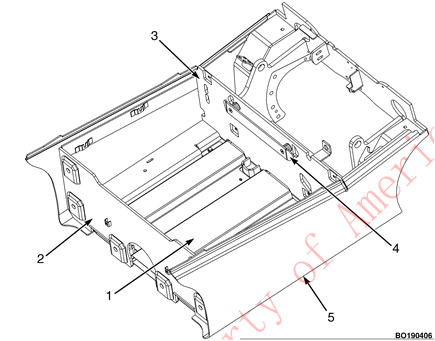

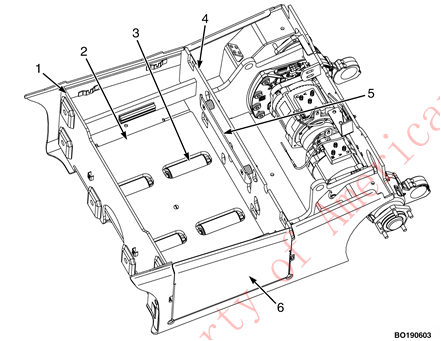

Frames, Covers, and Floor Plates

The frame is a single weldment with mounts for the

Check the condition of the

Figure 26. Frame and Covers Check

Hydraulic System

WARNING: At operating temperature the hydraulic oil is HOT. DO NOT permit the oil to contact the skin and cause a burn.

WARNING: Always wear the proper protective equipment including eye protection and petroleum-resistant gloves when handling hydraulic oil. Thoroughly wash oil from exposed areas of skin as soon as possible.

CAUTION: DO NOT permit dirt to enter the hydraulic system when the oil level is checked or the filter is changed.

Never operate the pump without oil in the hydraulic system. The operation of the hydraulic pump without oil will damage the pump.

Some parts of the mast move at different speeds during raising and lowering.

Hydraulic Hoses, Hose Fittings, and Clamps

Inspection of Mast, Carriage, Header Hoses, Lift Chains, and Attachments

WARNING :Lower the lift mechanism completely. Never allow any person under a raised carriage.

DO NOT put any part of your body in or through the lift mechanism unless all parts of the mast are completely lowered and the lift truck motor is OFF.

WARNING : Always wear the proper protective equipment including eye protection and petroleum-resistant gloves when handling hydraulic oil.

Thoroughly wash oil from exposed areas of skin as soon as possible.

WARNING :Never check for leaks by putting hands on hydraulic lines or components under pressure.

Hydraulic oil under pressure can be injected into the skin.

Visually inspect hoses/fittings for hydraulic leaks

hose covers for cuts

cracks

exposed reinforcement

defective/broken clamping devices or sheaves

proper tracking during operation

NOTE: Chain anchor pins MUST be replaced any time chains are replaced.

Hydraulic Oil

WARNING :At operating temperature the hydraulic oil is HOT. DO NOT permit the oil to contact the skin and cause a burn.

WARNING: Always wear the proper protective equipment including eye protection and petroleum-resistant gloves when handling hydraulic oil.

Thoroughly wash oil from exposed areas of skin as soon as possible.

CAUTION: DO NOT permit dirt to enter the hydraulic system when the oil level is checked or the filter is changed.

Never operate the pump without oil in the hydraulic system. The operation of the hydraulic pump without oil will damage the pump.

Hydraulic Oil Standard Truck (Total Capacity)

Hydraulic Oil Cooler/Freezer Truck (Total Capacity)

Hydraulic Oil Sub-Zero Construction (Total Capacity)

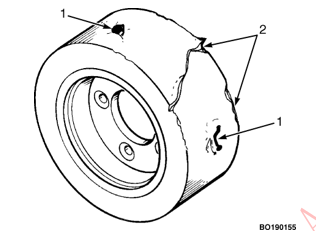

Steering Tire and Wheel Assemblies

Tire and Wheel

Figure 25. Tire Check

Battery

WARNING: Never put tools or other metal on the battery. Metal on the battery can cause a short circuit and possible dam- age or injury.

The acid in the electrolyte can cause injury. If the elec- trolyte is spilled, use water to flush the area.

Make the acid neutral with a solution of sodium bicarbonate (soda). Acid in the eyes must be flushed with water immediately.

Batteries generate explosive fumes. Keep the vents in the caps clean. Keep sparks or open flames away from the battery area. DO NOT make a spark from the battery connections.

Disconnect the battery when doing maintenance.

There can be one of two types of batteries. One type has removable cell caps. The other type has sealed cells.

The sealed batteries require a different charger, the electrolyte level or specific gravity cannot be checked and water cannot be added to the electrolyte.

See Battery Specifications to check for correct battery dimensions.

Battery Restraint

Figure 36. Standard Battery Restraint System

Figure 37. Optional Battery Restraint System With Side Rollers

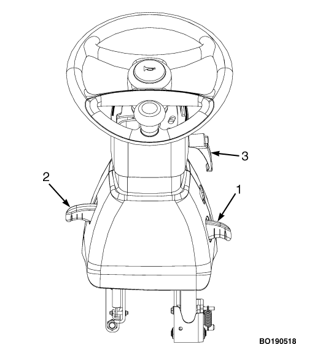

Steering System

Automatic Parking Brake

Service Brake

Sliding Surfaces

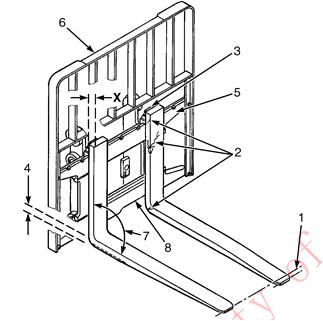

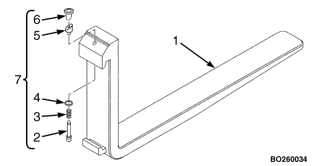

Forks

Figure 29. Forks Check

Fork Tip Alignment

Fork Guides and Pins

WARNING: DO NOT try to move a fork without a lifting device. The forks can weigh 45 to 115 kg (99 to 254 lb).

Figure 31. Fork Lock Pin Assembly

Electric Circuits

Horn

Lights

Alarms

Seat Switch

Direction and Speed Control Pedals

Safety Labels and Operating Manual

Safety labels are installed on the lift truck to provide information about possible hazards. It is important that all safety labels are installed on the lift truck and can be read.

Steering Column Tilt Memory Lever

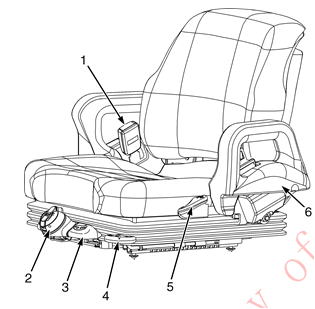

Seat Belt and Seat Rails

Operator Presence System Check

Source: Hyster