JUNGHEINRICH EFG 113 Forklift Trucks 500 Hours /3 Months

The JUNGHEINRICH EFG 113 Forklift Trucks 500 Hours /3 Months keeps your forklift in prime working condition. This procedure allows quick identification of parts that need repair or replacement.

JUNGHEINRICH EFG 113 Forklift Trucks 500 Hours /3 Months

The JUNGHEINRICH EFG 113 Forklift Trucks 500 Hours /3 Months keeps your forklift in prime working condition. This procedure allows quick identification of parts that need repair or replacement.

Chassis/ superstructurer

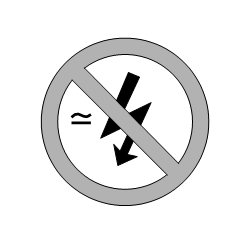

1.7 Check if labels are:

Drive unit

2.1 Check the transmission for noises and leakage

The electronic drive controller allows the drive motor speed to be continuously regulated and thus ensures

2.2 Check the transmission oil level

Gear oil must not run into the ground. To prevent this, put an oil pan underneath the gear box.

Let off oil

Refill oil

Wheels:

Steering:

Brake system

5.1 Check for correct function and adjustment

There are four possibilities available to decelerate the truck:

Service brake:

Coasting brake:

Reverse brake (single-pedal):

Depending on the truck type, the driving direction switch can be located

Reversing brake (dual-pedal) o

Locking brake:

5.2 Check the brake:

5.3 Check the brake lines, connections and brake fluid level

Hydraulic Sytem

6.3 Check the oil level

6.4 Check

Electric System

7.2 Check all cables for secure connection and damage

Electric motors:

Battery:

9.4 Clean battery connections, check for tight fit

In order to prepare the truck for work following delivery or transportation, the following operations must be performed:

Hoist frame

10.2 Check lift chains and chain guide for:

10.6 Check fork tines and fork carrier for :

10.7 Visual check of :

General Measurements

Demonstration

Source: Jungheinrich