Steam Tunnel Semi-Annual Efficiency & Safety Checks

The biannual inspections of the steam tunnel is to secure its safety and efficiency.

Steam Tunnel Semi-Annual Efficiency & Safety Checks

The biannual inspections of the steam tunnel is to secure its safety and efficiency. Benefits of regular safety checks include detection in advance structural or functional problems that might jeopardize the security or functionality of the tunnel, avoidance of higher costs of repair and disruptions due to late interventions and better forecast of future degradations or problems that might arise in the structure.

*** LOTO Confirmation Statement - DO NOT EDIT/REMOVE ***

All hazardous energy has been isolated using LOTO procedures?

All potential stored or residual energy has been relieved, disconnected, restrained, lowered, and/or otherwise rendered safe?

Lock Out Tag Out

Food Safety Pre-Check

LOTO Performed

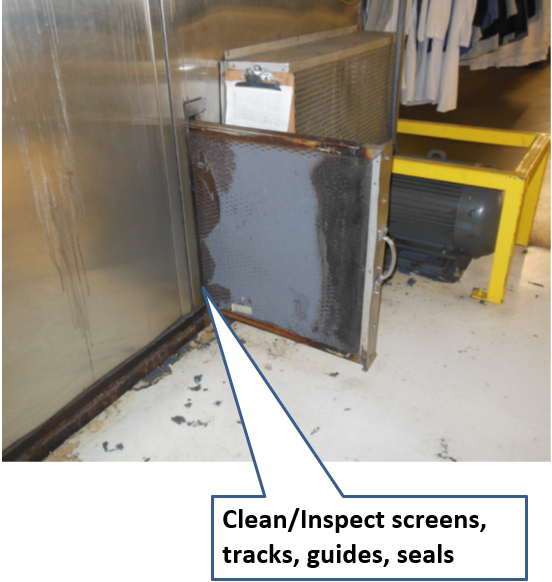

Clean Lint Screen Area

Picture Before Cleaning

Add or drag pictures

Clean all areas of lint collection system. Check lint screen guides and seals.

Picture After Cleaning

Add or drag pictures

Check lint screen

Check lint screen for rips and tears. Replace lint screen if damaged. Inspect the lint screen for ‘clogging’, melted material, or build up

Pressure wash lint screen to remove all build-up if applicable.

If it can be cleaned adequately then no replacement necessary. If it cannot be cleaned adequately it must be replaced.

Clean Lint from Inside Tunnel (garment side)

Picture Before Cleaning

Add or drag pictures

Clean lint from inside tunnel including floor, walls, ceiling, louvers, etc..

Picture After Cleaning

Add or drag pictures

Clean Lint from Inside Tunnel (burner side)

Picture Before Cleaning

Add or drag pictures

Clean lint from inside tunnel including floor, walls, ceiling, louvers, etc..

Picture After Cleaning

Add or drag pictures

Clean Lint on Outside Tunnel

Picture Before Cleaning

Add or drag pictures

Clean lint/residue from outside tunnel including top, sides, ends, etc..

Picture After Cleaning

Add or drag pictures

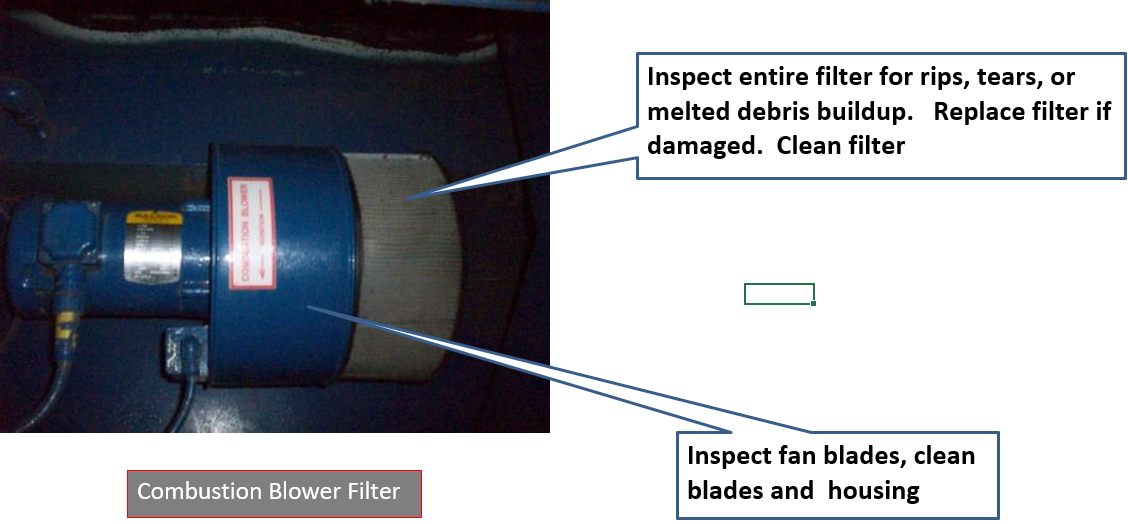

Check/Clean Combustion Blower and Filter

Picture Before Cleaning

Add or drag pictures

Remove any accumulated lint. Inspect wheel and housing integrity. Clean pre filter if equipped and change as necessary.

Picture After Cleaning

Add or drag pictures

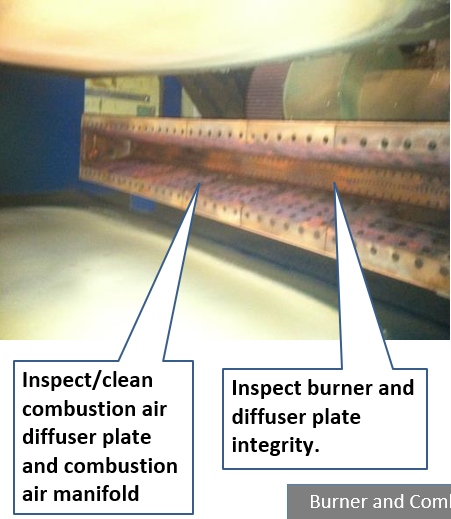

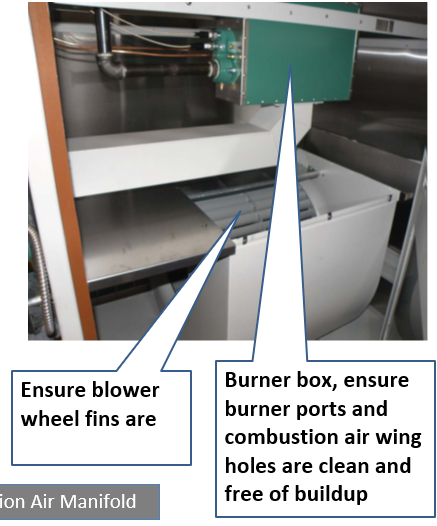

Check/Clean Burner and Combustion Air Manifold

Picture Before Cleaning

Add or drag pictures

Remove any accumulated lint from Manifold and diffuser plate. Inspect burner and diffuser plate integrity.

Picture After Cleaning

Add or drag pictures

Vacuum out Control Panel

Picture Before Cleaning

Add or drag pictures

*ENSURE ALL POWER IS OFF TO Tunnel*

Vacuum out any lint or debris from electrical control panel.

Picture After Cleaning

Add or drag pictures

Seals

Check to ensure all internal wall panels are sealed and no steam is escaping.

Food Safety Post-Check

Source: 23K Justice IL - Cintas (Community Member)