Doosan G15S-5 Pneumatic Forklift 2000 Hours / 1 Year

The Doosan G15S-5 Pneumatic Forklift 2000 Hours / 1 Year completely covers all parts of the forklift. Ensure that the quality of the forklift is maintained by performing yearly maintenance.

Doosan G15S-5 Pneumatic Forklift 2000 Hours / 1 Year

The Doosan G15S-5 Pneumatic Forklift 2000 Hours / 1 Year completely covers all parts of the forklift. Ensure that the quality of the forklift is maintained by performing yearly maintenance.

You must read and understand the warnings and instructions contained in the Safety section of this manual, before performing any operation or maintenance procedures.

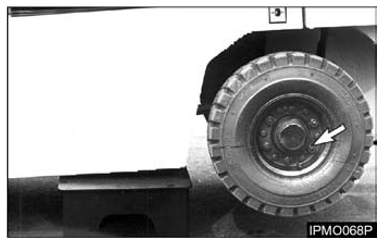

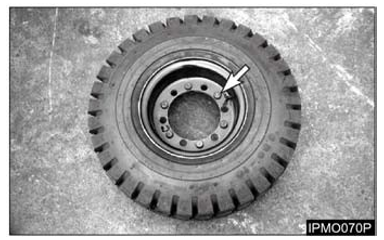

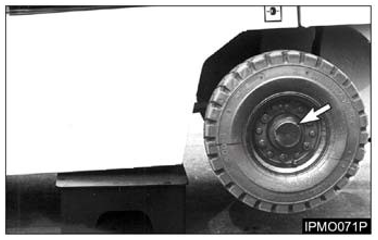

Steer Wheel Bearings – Reassemble

Park the lift truck level with the forks lowered, park- ing brake engaged, transmission in NEUTRAL and the engine stopped.

NOTE : Deflate tire before removing wheel nuts from the truck.

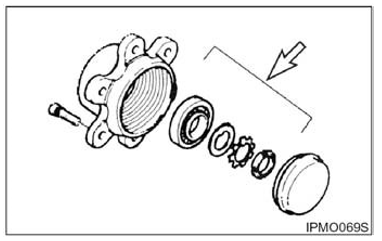

Drive Wheel Bearing - Reassemble

Consult your DOOSAN lift truck dealer for the proper wheel bearing reassembling procedure.

Reassembling of bearings and adjustment procedure must be made by a trained mechanic or deal- er personnel.

Cooling System – Clean, Change

WARNING: At operating temperature, the engine coolant is hot and under pressure. Steam can cause personal injury.

Check the coolant level only after the engine has been stopped and the filler cap is cool enough to touch with your bare hand. Remove the filler cap slowly to relieve pressure.

Coolant is included antifreeze for forbidding corrosion. Avoid contact with the skin and eyes to prevent personal injury. Use all cleaning solution with care.

The Lift truck must be level, the forks lowered, the parking brake engaged, the transmission in NEUTRAL and the engine stopped and cool.

V2403 Diesel Engine

G420F(E) 2.0L LPG/Gasoline Engine

NOTICE: Hold the drain port when the radiator drain valve is turned because the tank and the drain port are separated.

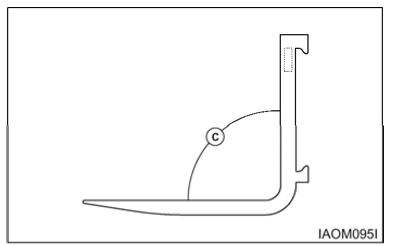

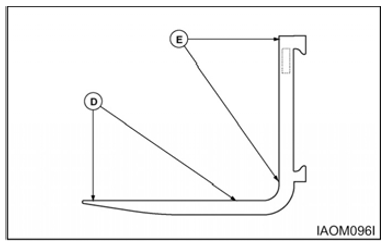

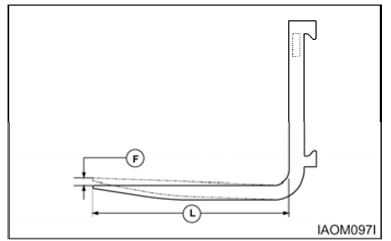

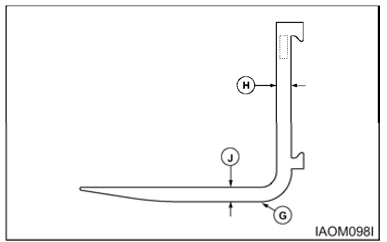

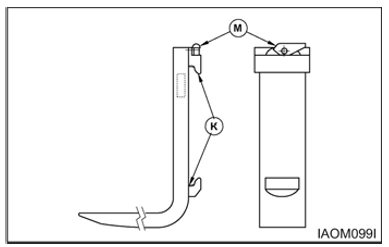

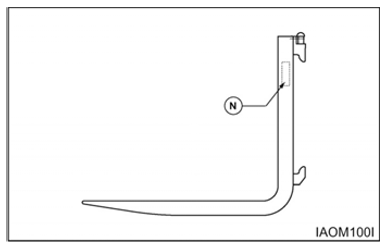

Fork - Inspect

Forks should be inspected, at a minimum, every 12 months. If the truck is being used in a multi-shift or heavy duty operation, they should be checked every six months.

Source: Doosan