2015 DOOSAN G20SC-5 Pneumatic Forklift 1000 Hours/6 Months

The 2015 DOOSAN G20SC-5 Pneumatic Forklift 1000 Hours/6 Months is a preventive maintenance form done semi-annually. It contributes to a safer working environment and prevent costly lift truck repairs. Maximize your forklifts capabilities by consistently performing maintenance.

2015 DOOSAN G20SC-5 Pneumatic Forklift 1000 Hours/6 Months

The 2015 DOOSAN G20SC-5 Pneumatic Forklift 1000 Hours/6 Months is a preventive maintenance form done semi-annually. It contributes to a safer working environment and prevent costly lift truck repairs. Maximize your forklifts capabilities by consistently performing maintenance.

You must read and understand the warnings and instructions contained in the Safety section of this manual, before performing any operation or maintenance procedures.

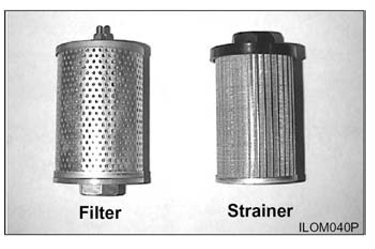

Hydraulic Return Filter, Breather & Strainer - Check, Change

WARNING: Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Park the lift truck level with the forks lowered, park- ing brake engaged, transmission in NEUTRAL and the engine stopped.

Engine Valve Lash (Diesel Engine Only) – Check, Adjust

Lift Chains - Test, Check, Adjust

Lift Chain Wear Test

Take the following steps to check chain wear.

*Chain wear rate (%)

Check for Equal Tension

WARNING: Personal injury can be caused by sudden movement of the mast and carriage. Keep hands and feet clear of any parts that can move.

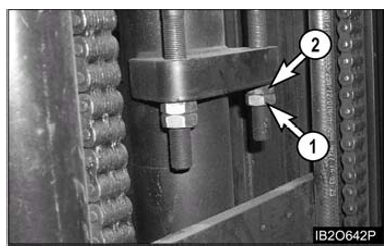

Lift Chain Adjustment

Typical example for carriage equal tension

If the tension is not the same on both chains, take the procedure as follows.

NOTE : If carriage height is not correct, make adjustments by following procedures.

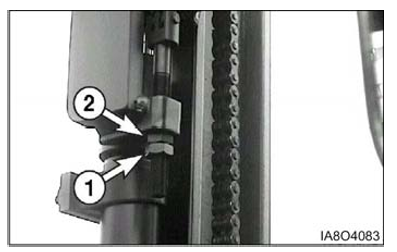

Carriage Chain Adjustment

Make sure that carriage height is correct. If correct, adjust the chain for equal tension. If not, adjust the chain for correct carriage height by adjusting anchor nuts(1),(2).

NOTE : See the previous section, “Carriage Roller Extrusion” in “When Required”. for proper height of carriage.

Mast Chain Adjustment - FF,FFT Mast

Typical example for FF mast

Typical example for FFT mast

NOTE : See the previous section, “Carriage Roller Extrusion” in “When Required”. for proper inner mast height.

Transmission Oil & Strainer- Clean, Change

See topic, “Transmission Oil & Strainer - Clean, Change” in “First 50-100 Service Hours”.

Air Intake System - Change

Changing Primary Element

Changing Secondary Element

Replace the secondary element after the primary element has been cleaned three times or 6 months.

NOTICE: Always replace the secondary element. Do not attempt to reuse it by cleaning.

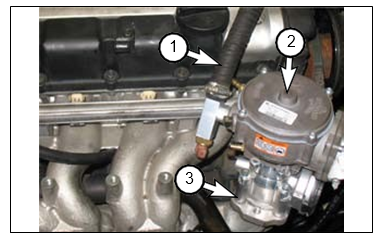

Inspect Coolant Hoses (LP, Dual Fuel Engines Only)

LP Regulator/Converter Inspection (LP, Dual Fuel Engine Only)

NOTE : For pressure testing and internal inspection of the pressure regulator/converter, refer to the pressure regulator/converter section of the service manual.

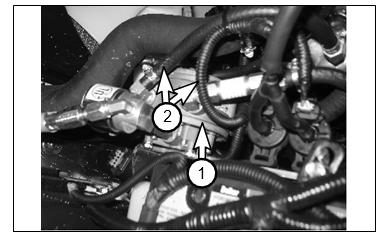

Fuel Lines & Fittings - Check

Inspect Mixer Assembly (G420F(E) Engine Only)

Inspect Throttle Assembly (G420F(E) Engine Only)

NOTE : Refer to the LP mixer and throttle section of the service manual for procedures on removing the mixer and inspecting the throttle plate.

Source: Doosan