Walinga Ultra- Veyors (AG) 100 Hours Maintenance

Walinga Ultra- Veyors (AG) 100 Hours Maintenance

MAINTENANCE SAFETY

Follow good shop practices:

5.1.1 FLUIDS AND LUBRICANTS

5.1.2 GREASING

Refer to Section 5.1.1 for recommended grease. Use the Service Record checklist provided to keep a record of all scheduled servicing.

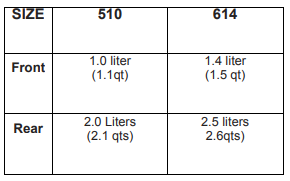

Fig. 5.5 BLOWER RESERVOIRS

Fig. 5.6 PRESSURE RELIEF VALVE

5.2.3 AIRLOCK

The airlock acts as a seal between the vacuum and atmosphere sides of the machine and is located at the bottom of the collector cyclone tank.

As the airlock rotor turns, a pocket is filled with material when it points upward. As the pocket rotates, it is moved to the bottom where the material drops out of the pocket into the discharge pipe.

Efficient operation of the airlock requires a close fit between the tips of the rotor and the case to maintain a seal between vacuum and atmosphere sides.

When checking or maintaining the airlock, follow this procedure:

Fig. 5.15

Fig. 5.16 AIRLOCK

Source: Walinga