Caterpillar D3K, D4K and D5K: Maintenance (Initial 500 Service Hours)

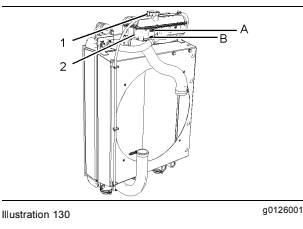

This procedure that is done for the 1st initial 500 Service Hours focuses on your equpment's cooling system coolant sample. It also provides the complete list of guidelines for proper sampling of the coolant.

Caterpillar D3K, D4K and D5K: Maintenance (Initial 500 Service Hours)

This procedure that is done for the 1st initial 500 Service Hours focuses on your equpment's cooling system coolant sample. It also provides the complete list of guidelines for proper sampling of the coolant.