Shake & Sundae Carpigiani Every 2 Weeks Maintenance

The Shake & Sundae Carpigiani Every 2 Weeks Maintenance Form helps you in performing inspections, minor repairs, cleaning, and upkeep, rather than waiting until something breaks down to take action. This will help you avoid unanticipated downtime due to equipment failure.

Shake & Sundae Carpigiani Every 2 Weeks Maintenance

The Shake & Sundae Carpigiani Every 2 Weeks Maintenance Form helps you in performing inspections, minor repairs, cleaning, and upkeep, rather than waiting until something breaks down to take action. This will help you avoid unanticipated downtime due to equipment failure.

After exactly 14 DAYS from the last brush cleaning, the machine must be thoroughly washed and restarted. It automatically locks out and must be disassembled, washed, sanitized and reassembled before operations can resume.

Every time product is dispensed the display indicates the number of days to the next brush cleaning.

THE FOLLOWING IS THE LIST OF OPERATIONS TO BE PERFORMED ON THE 14TH DAY IN ADDITION TO THE REGULAR DAILY AND WEEKLY CLEANING PROCEDURE.

NOTICE: MAKE SURE YOUR HANDS ARE CLEAN AND SANITIZED.

DISASSEMBLING AND CLEANING THE MILK SHAKE SIDE

NOTICE: ALL PARTS REMOVED FROM THE MACHINE SHOULD BE PLACED INTO A CONTAINER, AND TRANSPORTED TO THE SINK FOR CLEANING, RINSING AND SANITIZING.

CLEANING THE SHAKE SYRUP SYSTEM

Wiping pick up tubes:

Cleaning the syrup lines:

Rinsing the syrup lines:

DRAINING AND CLEANING THE MILK SHAKE SIDE

WARNING : Every time the display shows “WASH TODAY” alarm, you have to push once the button in order to reset the alarm message.

Drain the Milk Shake

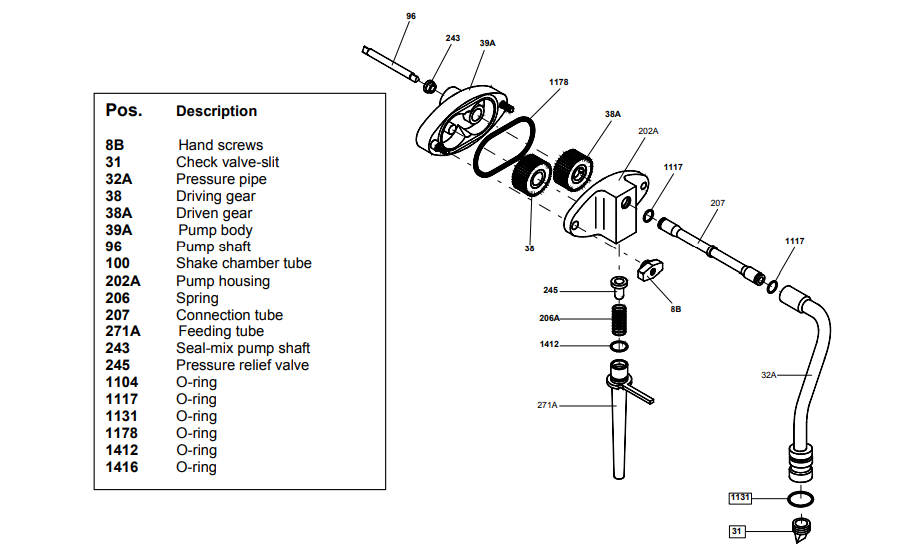

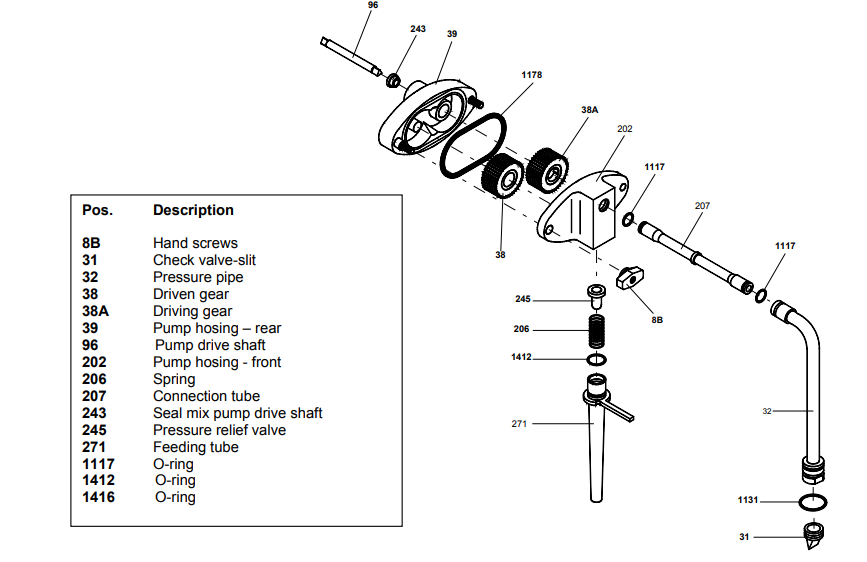

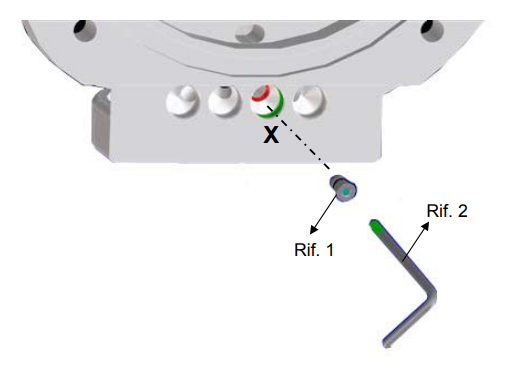

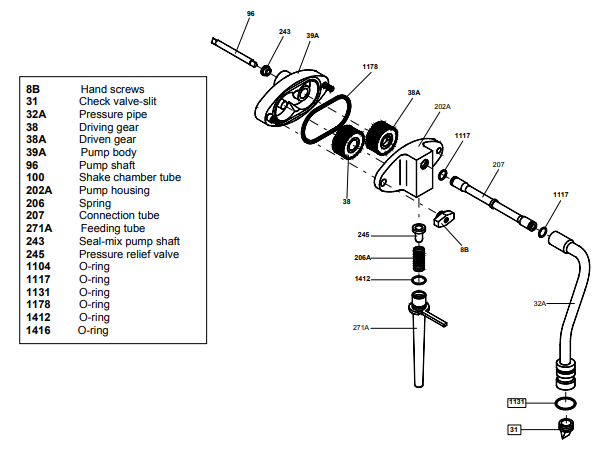

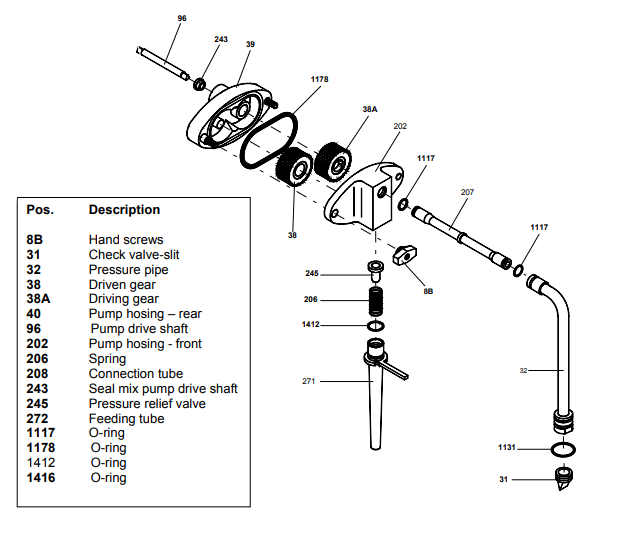

DISASSEMBLING OF THE SHAKE MIX PUMP

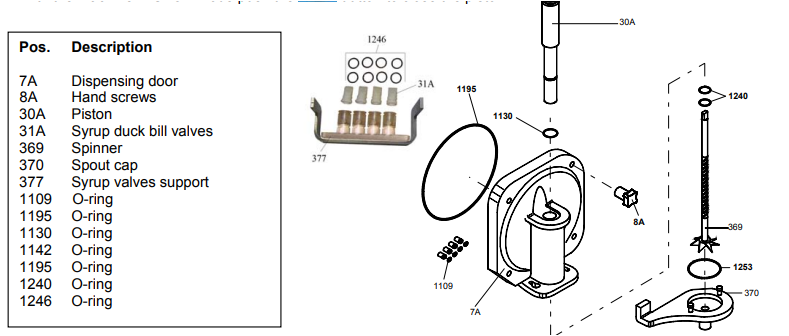

DISASSEMBLING OF THE SUNDAE DISPENSING DOOR

CAUTION: Before disassembling the dispensing head, make sure that the hopper and the cylinder are completely drained.

Using the o-ring extractor, remove:

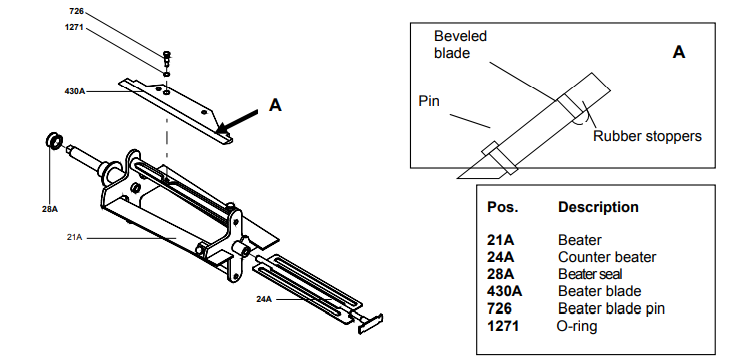

DISASSEMBLING OF THE SUNDAE BEATER

CAUTION : The beater seal is very important. It must be checked regularly for wear and tear. It must always be on the beater shaft and properly lubricated, during operation, otherwise mix will leak in the drip tray.

WASHING AND SANITIZING OF COMPONENT PARTS

Repeat steps 8 , 9 and 10 several times.

IMPORTANT!! We recommend not to wash the sundae and shake components together.

REASSEMBLY OF WASHED AND SANITIZED COMPONENT PARTS

REASSEMBLY OF THE SHAKE CYLINDER BEATER

CAUTION! Check the rubber stoppers onto the blade for integrity. Replace if worn or damaged. Carpigiani suggests to replace the blade once a year (please see the tune-up kit card).

WARNING Like all moving parts, the complete beater is also subject to wear and tear. For this reason, we recommend checking the amount of wear to parts in direct contact with one an-other (beater/beater idler and beater/cylinder walls) on a regular basis

In particular, make sure that the wear on the bushing on the beater idler is no more than 2 mm, as indicated by the marking on the bushing itself. If there is more than 2 mm wear, it is necessary to replace the beater idler.

CAUTION! The beater seal is very important. It must be checked regularly for wear and tear. It must always be on the beater shaft and properly lubricated, during operation, otherwise mix will leak in the drip tray.

REASSEMBLY OF THE SHAKE DISPENSING DOOR

Lubricate the O-rings and replace them in their respective position i.e.:

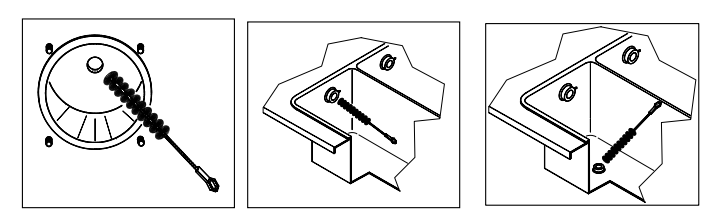

REASSEMBLY OF THE SHAKE MIX PUMP

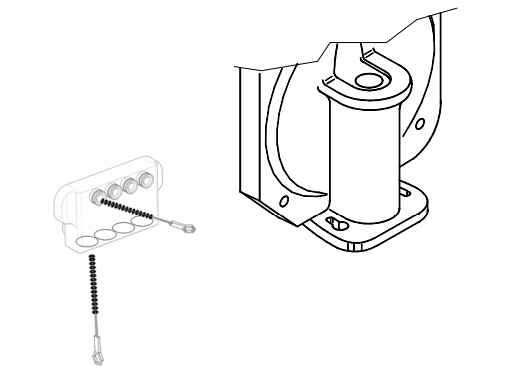

REASSEMBLY OF THE MIX HOPPER AGITATOR

REASSEMBLY OF WASHED AND SANITIZED COMPONENT PARTS

REASSEMBLY OF THE SUNDAE BEATER

IMPORTANT : Check the beater seal for integrity. Replace if worn or damaged. It should be replaced rather frequently.

REASSEMBLY OF THE SUNDAE DISPENSING DOOR

REASSEMBLING OF THE SUNDAE MIX PUMP

REASSEMBLING OF THE MIX TANK AGITATOR

SANITIZING OF THE ENTIRE MACHINE

Carry out the following operations for both shake side and sundae side of the machine.

NOTE: After the machine’s brush cleaning, and more precisely from the moment you close the front door (lid) of the machine, it is necessary to run the machine in production (by pushing PROD. button) within 60 minutes

After the 60 minutes, the machine does not accept the PROD. button any more and it sets to pasteurisation function automatically. In other words, you should make the “Sanitization of the whole machine“ and the “Mix Priming“ within 60 minutes, then push PR

SANITIZE THE HOPPER

SANITIZE THE PUMP AND FREEZING CYLINDER

DRAIN THE SANITIZER

SYRUP SANITIZING, PRIMING AND CALIBRATION (SHAKE SIDE)

Sanitizing the syrup lines:

Drain the sanitizer from the syrup lines

Priming the syrup lines with syrup:

WARNING: TO AVOID POTENTIAL BACTERIA GROWTH IN THE SYRUP SYSTEM DURING OPERATIONS, ALL THE SYRUP LINES MUST ALWAYS BE FILLED WITH SYRUP

Calibrate syrups as follows:

REPEAT THE CALIBRATION FOR EACH FLAVOUR.

MIX PRIMING

Reminder

After the machine’s brush cleaning, and more precisely from the moment you close the front door (lid) of the machine, it is necessary to run the machine in production (by pushing PROD. button) within 60 minutes.

After the 60 minutes, the machine does not accept the PROD. button any more and it sets to pasteurisation function automatically. In other words, you should make the “Sanitization of the whole machine“ and the “Mix Priming“ within 60 minutes, then push PR

Prime Hopper:

Connect the mix pressure pipe:

Source: Carpigiani (www.manualslib.com)