JUNGHEINRICH EFG 113 Forklift Trucks Every 50 service Hours/ Weekly

The JUNGHEINRICH EFG 113 Forklift Trucks Every 50 service Hours/ Weekly keeps your forklift in prime working condition. This procedure allows quick identification of parts that need repair or replacement.

JUNGHEINRICH EFG 113 Forklift Trucks Every 50 service Hours/ Weekly

The JUNGHEINRICH EFG 113 Forklift Trucks Every 50 service Hours/ Weekly keeps your forklift in prime working condition. This procedure allows quick identification of parts that need repair or replacement.

Chassis/ superstructure

1.5 Check safety belt for damages and function

Daily inspections of the condition and operatability of the safety belt should be carried out by the driver before using the industrial truck. . A malfunction can only be detected at an early stage by regular inspection.

Automatic blocking system test:

The automatic system must block the belt.

Do not operate industrial truck with defective safety belt but have it replaced immediately!

1.6 Check retaining system (option)

Wheels:

3.1 Check for wear and damage

Electric System

7.1 Check the instrument and indicators for correct functioning

Electric fuses of the base machine

Electric fuses o

Battery

9.1 Check the battery cables for damage and replace, if necessary

Safety regulations governing the handling of lead-acid batteries

Servicing staff: Recharging, servicing and replacing of batteries must only be per- formed by qualified personnel. The instructions contained in this operating manual, and the instructions of the manufacturer of the battery and of the battery recharging s

Fire protection measures

Servicing of batteries

Disposal of the battery

9.2 Check

Hoist frame

Apply grease to running paths and side run areas of idler pApply grease to running paths and side run areas of idler pulleys in the hoist frame profiles.ulleys in the hoist frame profiles.

10.3 Lubricate lifting chains and chain guides.

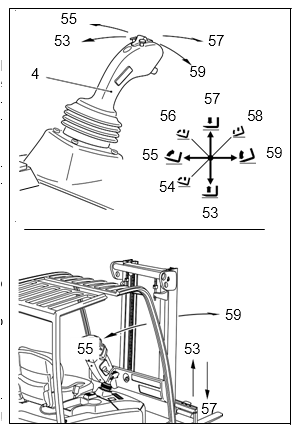

Lifting/lowering fork carrier

Combined function

Source: Jungheinrich