Doosan D33S-5 Pneumatic Forklift 250 Hours/ Weekly

The Doosan D33S-5 Pneumatic Forklift 250 Hours/ Weekly ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Doosan D33S-5 Pneumatic Forklift 250 Hours/ Weekly

The Doosan D33S-5 Pneumatic Forklift 250 Hours/ Weekly ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Hydraulic Return Filter – Change

WARNING: Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Park the lift truck level with the forks lowered, parking brake engaged, transmission in NEUTRAL and the engine stopped.

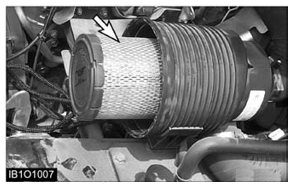

Air Intake System - Check, Clean

Precleaner (If Equipped)

NOTICE Never service cleaner with the engine running.

Servicing Filter Element

NOTICE: Never service filter with the engine running.

Service the air cleaner when the red target in the service indicator stays locked in the visible position with the engine stopped.

NOTICE : Do not allow dirty air to enter the intake hose when cleaning the inside of the air cleaner housing.

Cleaning Primary Filter Elements

WARNING: Pressure air can cause personal injury. When using pressure air for cleaning, wear a protective face shield, protective clothing and protective shoes. The maximum air pressure must be below 205 kPa (30 psi) for cleaning purposes.

NOTICE: Do not clean the elements by bumping or tapping them. Inspect filter elements after cleaning. Do not use a filter with damaged pleats, gaskets or seals.

When cleaning with pressure air, use 205 kPa (30 psi) maximum pressure to prevent filter element damage. When cleaning with pressure water, use 280 kPa (40 psi) maximum pressure to prevent filter element damage.

Have spare elements on hand to use while cleaning used elements. The primary element should be replaced after 6 months service or after cleaning no more than 3 times.

Air-205 kPa (30 psi) Maximum Pressure

Water-280kPa (40 psi) Maximum Pressure

Detergent

Checking Element

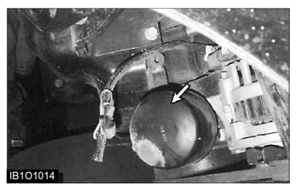

Brake Oil Level - Check

The brake reservoir is located on the left side of the steering column.

Hydraulic Oil Level – Check

WARNING: At operating temperature, the hydraulic tank is hot and under pressure. Hot oil can cause burns. Remove the filter cap only when the engine is stopped, and the cap is cool enough to touch with your bare hand. Remove the filter cap slowly to relie

Drive Axle Oil Level - Check

Park the lift truck on a level surface. Apply the parking brake. The engine at low idle. Place the directional control lever in NEUTRAL.

Mast, Carriage, Lift Chains & Attachments - Inspect, Lubricate

NOTICE: Lubricate chains more frequently than normal in applications where the lift truck is operating in an atmosphere which could cause corrosion of components or when lift truck must work in rapid lift cycles.

Steering Mechanism - Check, Lubricate

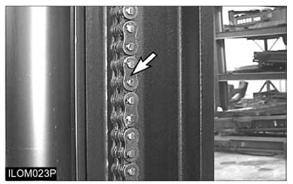

Battery Terminal - Clean, Inspect

WARNING: Batteries give off flammable fumes that can explode. Do not smoke when observing the battery electrolyte levels. Electrolyte is an acid and can cause personal injury if it contacts skin or eyes. Always wear protective glasses when working with ba

Engine Oil & Filter (LP & Gasoline Engine Only) - Change

Gasoline, LP Engine Crankcase

WARNING: Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

PCV Valve System - Inspect, Clean

G420F(E) Gasoline, LP and Dual Fuel Engines

G424F(E) LP and Duel Fuel Engines

G424I(E) LP and Duel Fuel Engines

G430FE LP Engine

Wheel Bolts & Nuts - Inspect

Inspect Tightness (D, G - Series)

Steer Wheels

Drive Wheels

Inspect Tightness (GC - Series)

Drive Wheels

Source: Doosan