Braun Washer Weekly PM

The benefits of maintaining your industrial washer can reduce breakdowns. Commercial washers and dryers are expensive pieces of equipment that can be prone to breaking down. This also improves efficiency and a longer machine life.

Braun Washer Weekly PM

The benefits of maintaining your industrial washer can reduce breakdowns. Commercial washers and dryers are expensive pieces of equipment that can be prone to breaking down. This also improves efficiency and a longer machine life.

*** LOTO Confirmation Statement - DO NOT EDIT/REMOVE ***

All hazardous energy has been isolated using LOTO procedures?

All potential stored or residual energy has been relieved, disconnected, restrained, lowered, and/or otherwise rendered safe?

Lock Out Tag Out

LOTO Performed

Utilize the Cintas ENERGY CONTROL PROGRAM Checklist when applying LOTO.

Check Air Leaks - Check for air leaks. Check air regulators and verify that set point is correct (set-point will vary by machine model; verify with machine manual). Walk around machine and listen for air leaks.

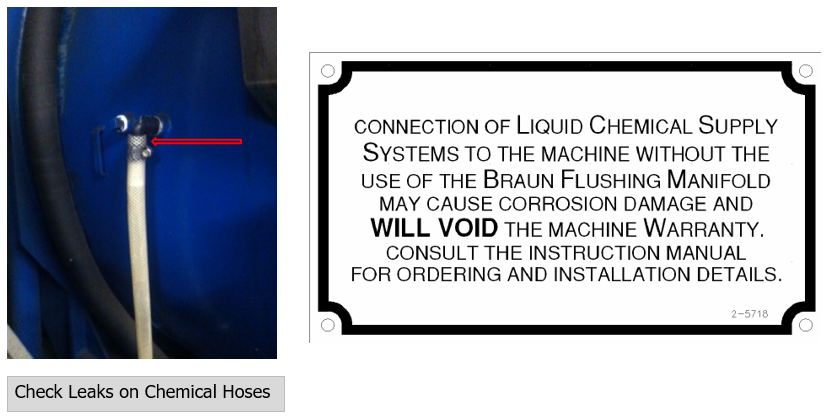

Check Chemical Leaks - Check for chemical leaks. Check chemical hoses; check chemical hose connectors to machine. See Appendix 1.

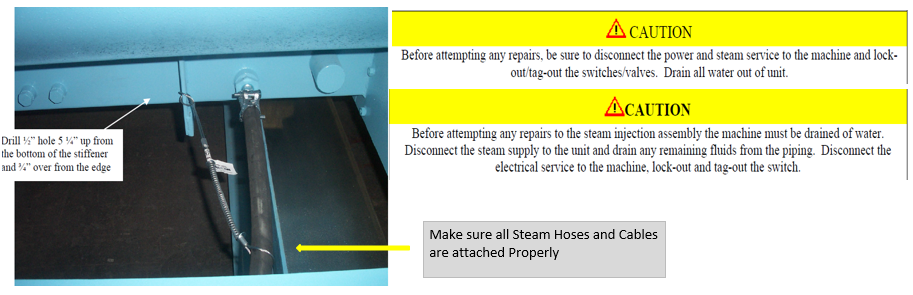

Check Steam Leaks - Check for steam leaks. Check shut-off valve from header to machine; check steam nozzle on bottom of washer; check steam operating valve; check all steam hoses. Check for steam hoses' retention cable to be present and not damaged. See Appendix 2.

Check Water Leaks - Check for water leaks. Check fill valves (hot, cold, tempered and/or reuse); check rubber fill hose for leaks. Check all pipe unions for leaks.

Check Hydraulic Leaks - Check hydraulic pump, hydraulic tilt cylinders and all hydraulic hoses for any Leaks. Repair all Leaks if found.

Check Drain Valves - Check drain valves for leaks; check while washer is running and during a typical wash cycle, verify that no water is leaking. During a drain step check that drain valve opens fully.

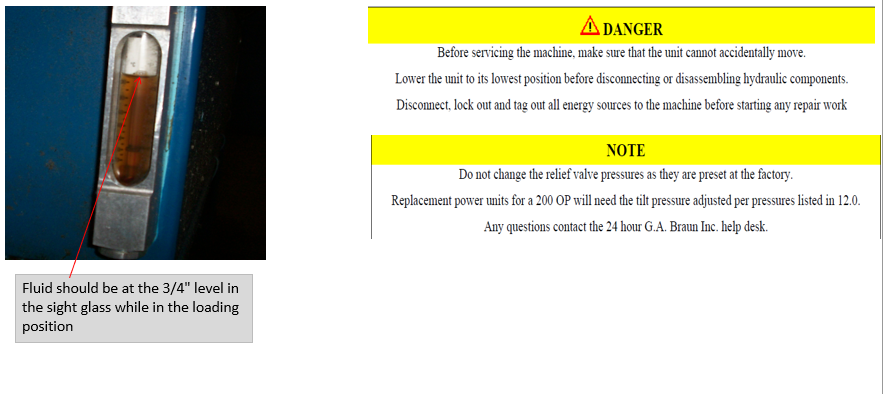

Check Hydraulic Oil Tank - Check hydraulic oil level in oil tank. Oil level should be 3/4" full when the machine is in the load position - if less than 3/4" level, refill. Verify that there are no oil leaks; if tank must be refilled more than once a month, there is a leak in the system. See Appendix 3.

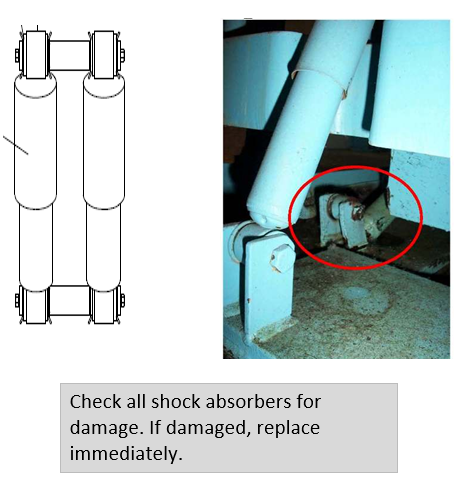

Check Shock Absorber - Check shock absorbers. Check shock bracket connections to machine. Repair brackets if needed. Check shocks for any damage. If damaged, replace. Check that shock is not leaking oil. Check shock temperature during extract with IR temp gun. You are looking for a temperature differential. See Appendix 4.

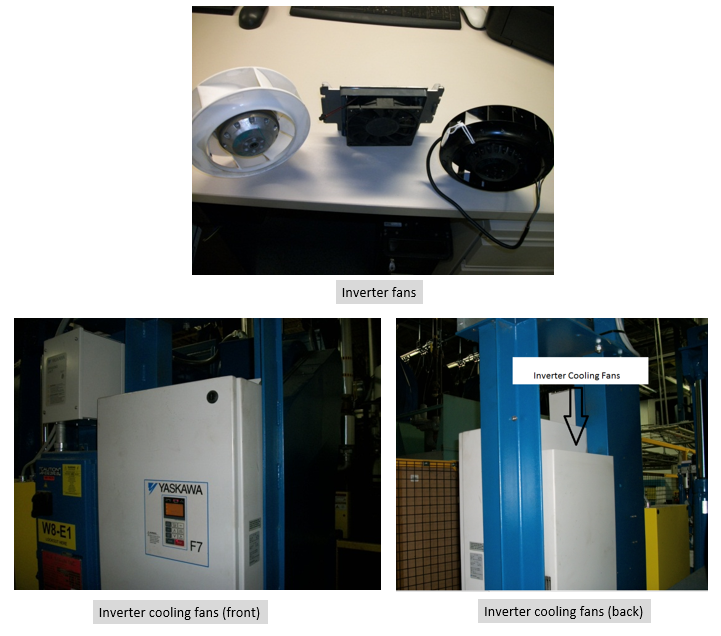

Clean Inverter Cooling Fan - Clean inverter cooling fan; blow out with compressed air. Remove any lint or debris. Machine power should be off when performing this task. See Appendix 5.

Clean Machine - Clean lint and visable debris from motor housings. Check mounting bolts and tighten where necessary. DO NOT OVERTIGHTEN. Throughly clean all stainless steel surfaces as recommended in sec.13 of the manual.

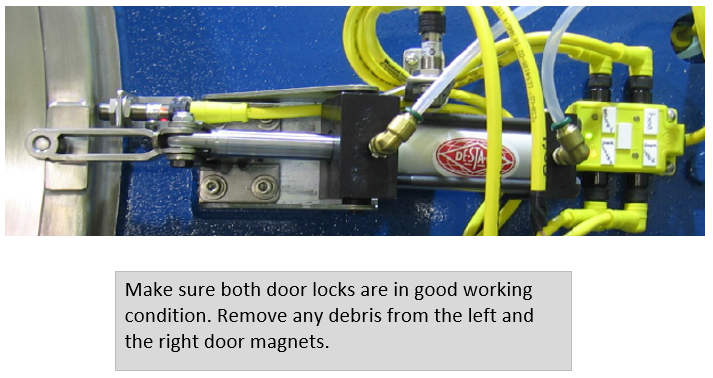

Check Door Locks - Repair or replace faulty door locks. Check both the left and right side door magnets for debris. Remove if necessary. See Appendix 6.

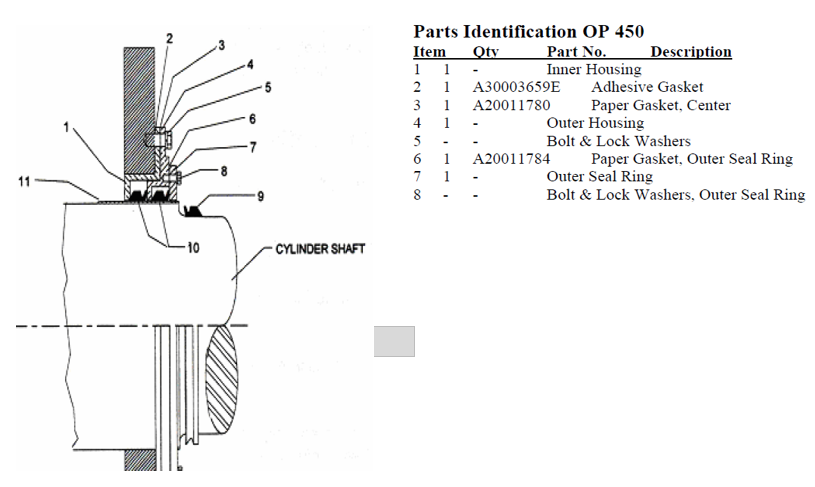

Shaft Seal Leaks - Visually inspect the main shaft seal for leaks. Note any leaks on PM. See Appendix 7.

Source: 24P DC Columbus - Cintas (Community Member)