Bi-Weekly Titan Maintenance - Titan #3 - #144

Follow this bi-weekly inspection, cleaning and maintenance of your equipment to ensure proper working condition and help prolong life span.

Bi-Weekly Titan Maintenance - Titan #3 - #144

Follow this bi-weekly inspection, cleaning and maintenance of your equipment to ensure proper working condition and help prolong life span.

INSTRUCTIONS

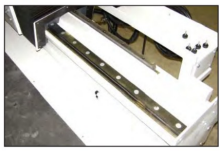

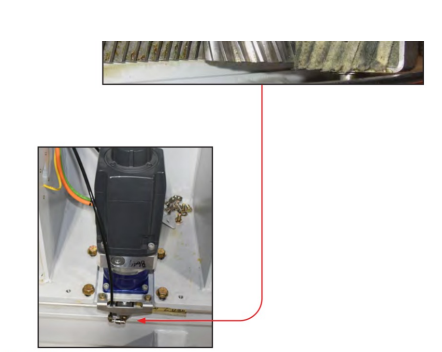

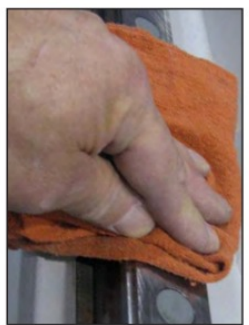

1. X Axis Linear Rails - inspect, clean and wipe (light film only) with Way Oil ISO VS Grade 68

Task 3.1 - X Axis Linear Rails: Inspect, clean, and lubricate the X axis rails

NOTE: The shroud does NOT have to be removed for this procedure.

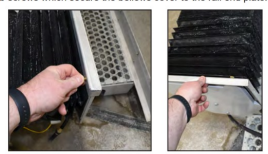

4. Inspect the rails and area around the rails. Excessive wear may indicate bearing failure and corrosion may indicate that the bellows cover is leaking.

TITAN CNC ROUTER

Service tip: A small amount of grease applied to the threads of each thumb screw will help prevent corrosion making the screw easier to remove the future.

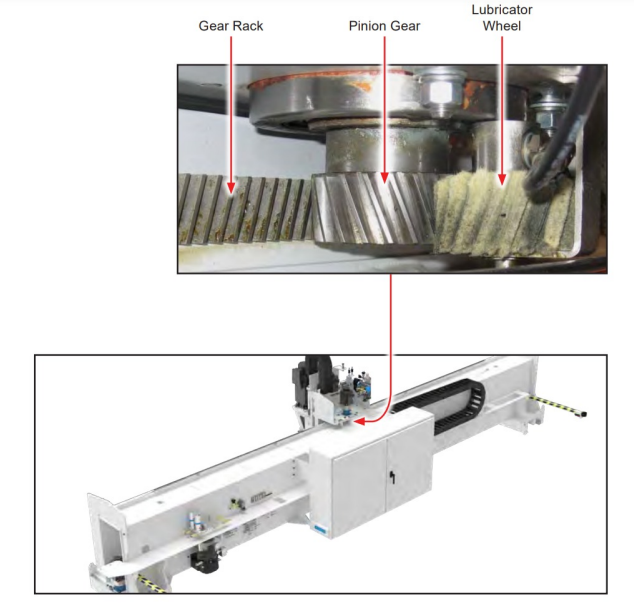

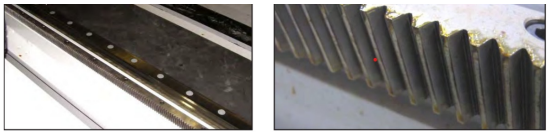

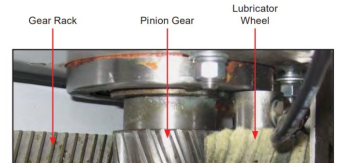

Inspect the rack and pinion for chipped or broken teeth and verify that the automatic lubrication system is functioning. X Axis

Inspect the gear rack and area around the gear rack. Excessive wear may indicate bearing failure and corrosion may indicate that the bellows cover is leaking. The X Axis gear rack and pinion are located on the back side of the bridge assembly. Inspect the rack and pinion for sharp or broken teeth. On both sides, verify that the pinion grease lubricator is supplying adequate but not excessive grease to both the pinion and gear rack. Only a thin film of grease is needed, not a gob of grease.

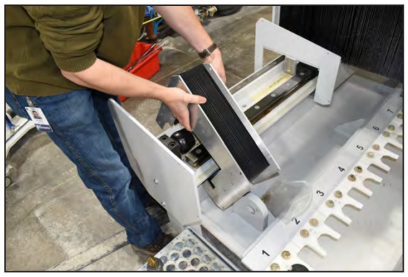

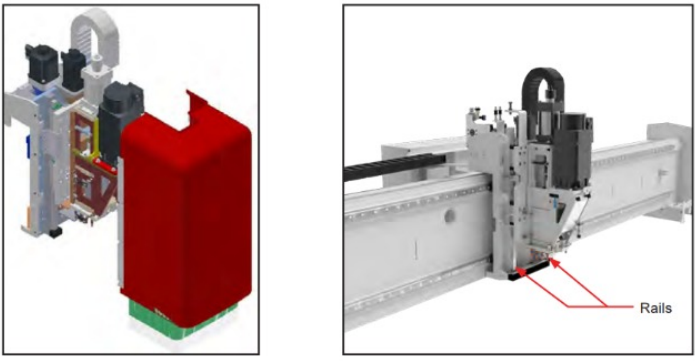

2. Y Axis Linear Rails - inspect, clean and wipe (light film only) with Way Oil ISO VS Grade 68

Task 3.2 - Y Axis Linear Rails: Inspect, clean, and lubricate the Y axis rails

TITAN CNC Router

5. Inspect the rails and area around the rails. Excessive wear may indicate bearing failure and corrosion may indicate that the bellows cover is leaking.

Service Tip: A small amount ofgrease applied to the threads of each thumb screw will help prevent corrosion making the screw easier to remove in the future.

Inspect the rack and pinion for chipped or broken teeth and verify that the automatic lubrication system is functioning. Y Axis

OPTIONAL: Lift out the collapsed bellows cover and set aside.

Inspect the exposed Y axis gear rack on both the away and toward side for chipped or broken teeth. Use the pendant to move the bridge as necessary to inspect the entire gear rack on both sides. Use the pendant to position the bridge at the Y- soft stop to gain access to the X+ side motor cover. Remove the access cover in the wall. At both ends of the bridge remove the four bolts which secure the protective cover to the bridge and then remove the cover.

Inspect the exposed Y axis gear rack on both the away and toward side for chipped or broken teeth.

Reassemble as follows:

3. Z Axis Linear Rails - inspect, clean and wipe (light film only) with Way Oil ISO VS Grade 68

Task 3.3 - Z Axis Linear Bearings: Inspect, clean, and lubricate the Z axis rails

Operator Name

Task completed Signature

Click here to sign

COMPLETION NOTES

Source: MaintainX (Community Member)