Emergency Eye Wash Station Weekly Inspection

Use this procedure for weekly inspection to ensure proper working condition of equipment and safety.

Emergency Eye Wash Station Weekly Inspection

Use this procedure for weekly inspection to ensure proper working condition of equipment and safety.

Eye wash easily identifiable

Clear pathway around eye wash station

Dust covers clean and disinfected

Eye wash bowls without cracks, dents or damages

Eye wash bowls clean from dirt/debris

Eye wash begins flow within one second of activation

Eye wash must have a continuous water flow

Water pressure removes dust cover

Check water pressure to be certain water height is accessible, but 8 inches of height or less

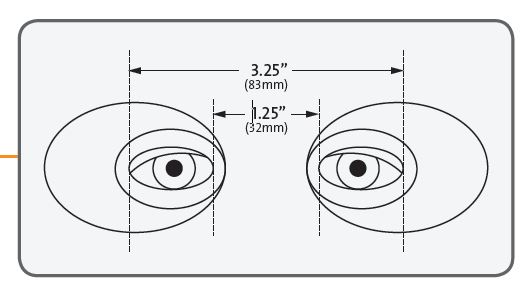

Ensure enough water flow to cover width of eyes

Water flow a steady even stream from both eye pieces

Flush station for one minute or until water is clean

Dry eye wash with clean cloth after testing

Source: True Blue Surfaces (Community Member)