Assembly

The dryer will generally be assembled under supervision of Geelen Counterflow. This manual contains

general instructions how to assemble and connect electrical devices. The sequence of assembly depends

strongly on the local situation.

The dryer and cooler should be unloaded from truck or container before the assembly supervisor from

Geelen arrives.

During the assembly, a forklift truck with a minimal lifting capability of 3 metric tons and long forks should

be available.

Often parts are lifted in the building via the roof by means of a crane with a maximum load of approximately

five metric tons. The dryer will be pre-assembled in modules on the ground, as close as possible to the

building in order to avoid transport damage.

Assembly

The dryer will generally be assembled under supervision of Geelen Counterflow. This manual contains

general instructions how to assemble and connect electrical devices. The sequence of assembly depends

strongly on the local situation.

The dryer and cooler should be unloaded from truck or container before the assembly supervisor from

Geelen arrives.

During the assembly, a forklift truck with a minimal lifting capability of 3 metric tons and long forks should

be available.

Often parts are lifted in the building via the roof by means of a crane with a maximum load of approximately

five metric tons. The dryer will be pre-assembled in modules on the ground, as close as possible to the

building in order to avoid transport damage.

Compress Air

Compress Air

Compressed air has to be dry with a minimal pressure of 6 bar and a maximum pressure of 8 bar. The use of lubricated air is advised. For compressed air supply every solenoid valve must be provided with a valve to make the system pressure less. Synthetic air ducts or connections must not be mounted against bin, hood and air ducting. In case of a fire these synthetic ducts can melt.

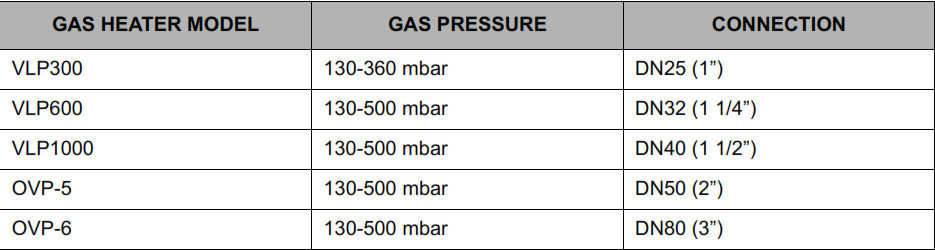

Gas Connection

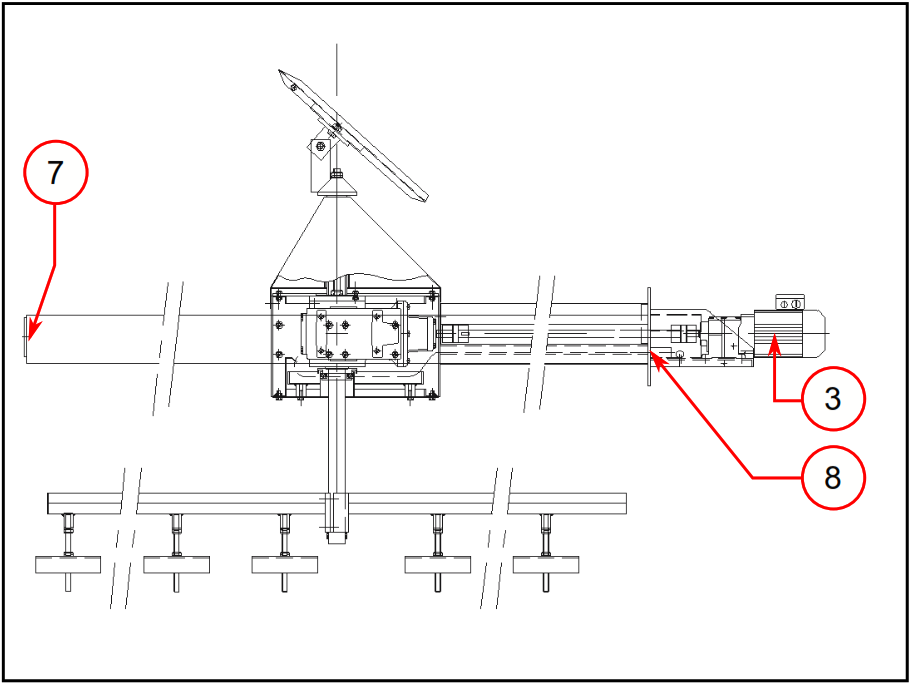

Rake with torque limiter

Rake with fixed height (option) The drive of the rotating product distributor/rake is supplied completely pre-assembled.

Assembly the fram

The drive of the rotating product distributor/rake is supplied completely pre-assembled.

Check by turning the drive shaft manually

Torque limiter

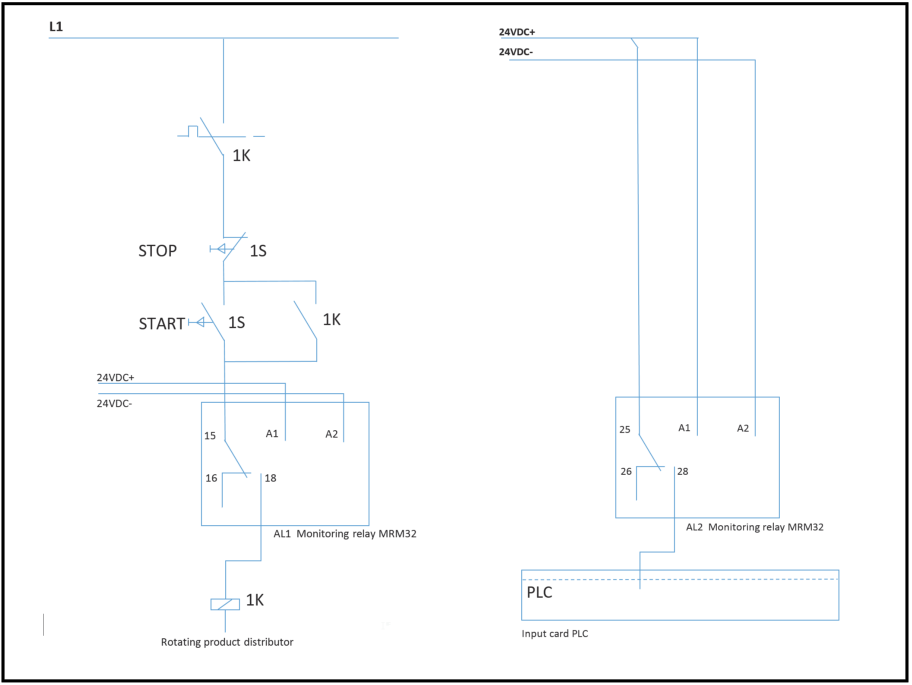

The torque limiter must be installed according to the diagram below; in case a PLC is used, the second output is used for an input of the PLC generating an alarm

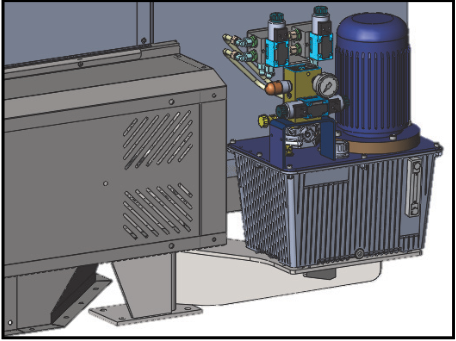

Hydraulic Unit

For transportation reasons the hydraulic unit is supplied separately.

Dryers

The support of the dryer’s discharger is fitted with a stationary support for the hydraulic unit. Place the hydraulic unit on the support and secure it with bolts.

Connections can be made

Rotating Sensor

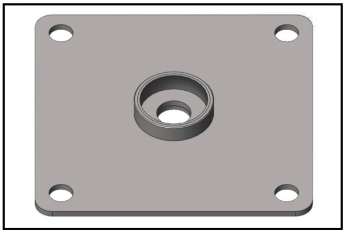

Fixed Position

In the fixed position the sensor is screwed in a base plate and detects the product level at that particular location.

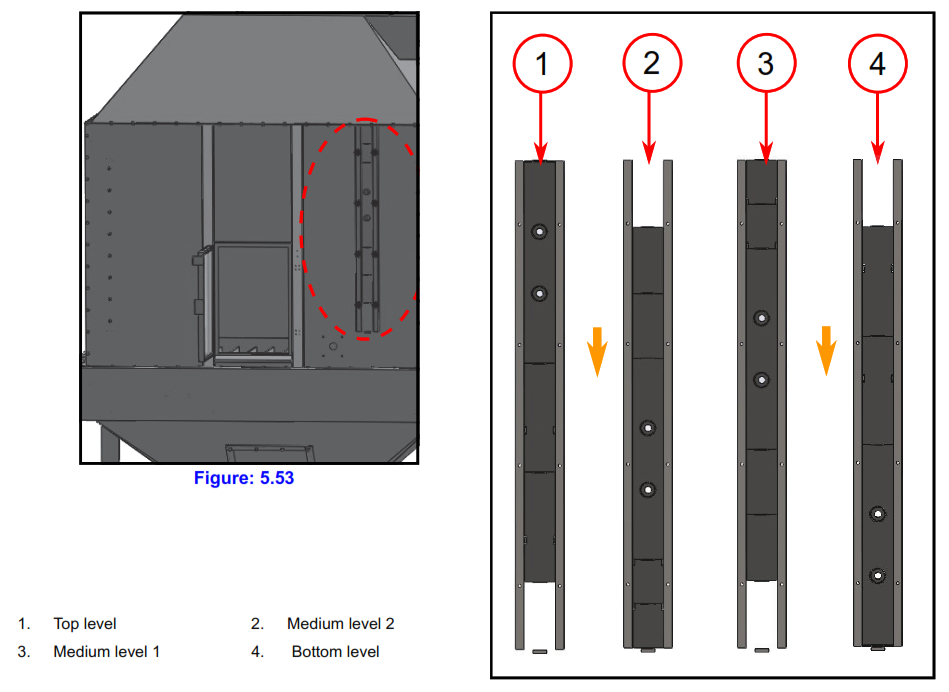

Movable Position

In case of a movable position, different cover plates are used in order to set the height for the level sensor. The plates can be mounted in 4 different ways, every height can be reached:

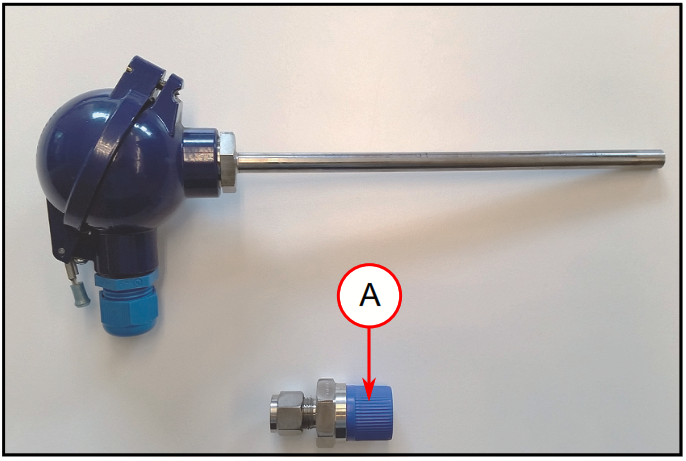

Temperature Probe

For measuring air temperatures in order to control and monitor the process during product cooling/drying, temperature probes can be installed in the machine and air system.

PT100 Installation

Source: Geelen Counterflow (Community Member)