Steel Pallet Racking Inspection

This inspection procedure outlines the steps for assessing the condition of steel pallet racking to ensure structural integrity and safety in warehouse environments.

Steel Pallet Racking Inspection

This inspection procedure outlines the steps for assessing the condition of steel pallet racking to ensure structural integrity and safety in warehouse environments.

Warning: This inspection requires trained personnel!

Enter the date and time of the inspection

Upload a photo of the inspected racking

Add or drag pictures

Beams

Beams Are beams overloaded?

A large amount of deflection indicates overloading of the racking. Where two beams connect at an upright, the beam connectors should be parallel. If racking is or has been overloaded, the beam connectors may be deformed (form a ‘V’). There will also be evidence of ‘permanent set’ in unloaded beams. In this situation, the racking should be inspected by a competent person or engineer.

Are beams or welds damaged?

Check for obvious signs of beams being hit by a pallet or forklift. Damaged beams should be replaced. If a beam has been hit and is only showing minor damage, ensure welds are checked by a competent person for cracking.

Are beam connectors or safety clips missing?

Examine beams for damage and replace missing clips. Replacements must be of a design approved by the equipment manufacturer. If clips are regularly being dislodged, contact the manufacturer or installer to determine why and implement corrective action.

Has a beam popped out of its upright?

If a beam has popped out this will mean it is only suspended on one end connector and could collapse.

Working load limits

Are rack load signs posted?

Ensure bays display the SWL signs provided by the designer / installer and the rack configurations have not been altered.

Uprights and footplates

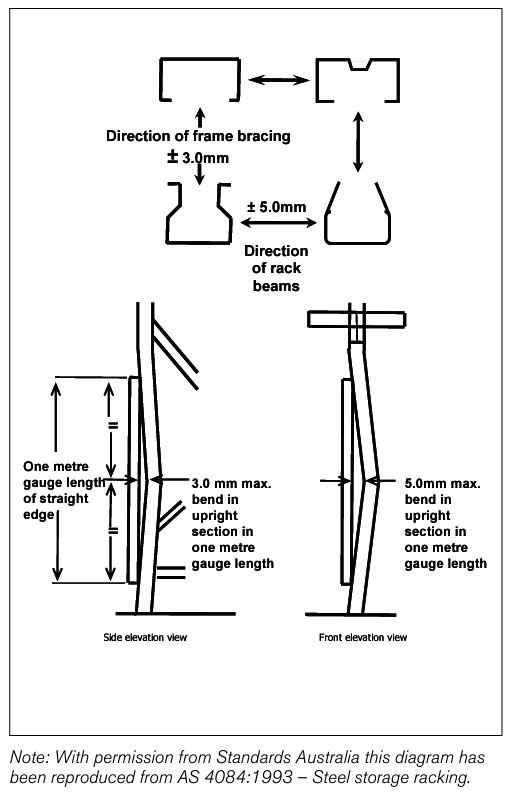

Are uprights damaged?

If an upright shows significant damage (see Figure 4), is twisted or contains splits or cracks, replace it or splice in a new section. Splices should be approved by the equipment manufacturer. If the upright is damaged, replace it and the footplate.

Are splices in good condition?

Check the condition of all splices. They should be above the first beam level, not below 1.5m, and no more than one splice should be between any two adjacent beam levels.

Out of plumb

Is the racking vertical?

Out of plumb racking is usually caused by incorrect installation but also as a result of impact, overloading, or settling of the floor slab. Contact the manufacturer or installer.

Braces

Are racking braces damaged?

Replace bent, horizontal or diagonal braces. For bracing, the member deviation from a 1m long straight edge in either plane should not exceed 10mm.

Floor fixings

Are floor fixings installed?

Check floor fixings are installed and undamaged. If damaged, replace it and the footplate. At least two anchors are required in each footplate. Note: To reduce the damage caused by pallets hitting the uprights, footplates and bracing while being lifted by forklifts, some workplaces install racking with beams, at knee height, in the bottom bay. This can also assist with manual picking activities as it raises the height of the items to be picked.

Any damages or deformations found?

Enter the number of damaged racks

Sign off on the inspection

Click here to sign

Source: Entegra Signature Structures (Community Member)