Manitowoc Blend-In-Cup® (BIC) Manual Fill Beverage System Monthly Maintenance

The Manitowoc Blend-In-Cup® (BIC) Manual Fill Beverage System Monthly Maintenance helps you in several ways: avoid expensive repairs, reduce downtime, keep beverage quality high, and extend the life of your equipment meaning you get to enjoy your investment for more years to come. This monthly maintenance form will help your equipment working in optimal conditions, leading to fewer failures, better productivity, higher profitability, and improved safety.

Manitowoc Blend-In-Cup® (BIC) Manual Fill Beverage System Monthly Maintenance

The Manitowoc Blend-In-Cup® (BIC) Manual Fill Beverage System Monthly Maintenance helps you in several ways: avoid expensive repairs, reduce downtime, keep beverage quality high, and extend the life of your equipment meaning you get to enjoy your investment for more years to come. This monthly maintenance form will help your equipment working in optimal conditions, leading to fewer failures, better productivity, higher profitability, and improved safety.

Air Filters

For units equipped with an air filter. Each month check the air filter to be sure it is clean and allows proper airflow.

Air Filter Location

Cleaning the Condenser Coil

Caution: Never use a high-pressure water wash for this cleaning procedure as water can damage the electrical components located near or at the condenser coil.

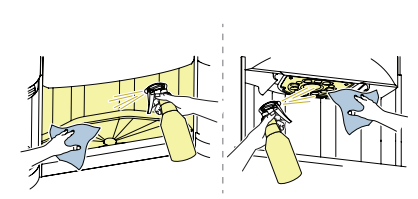

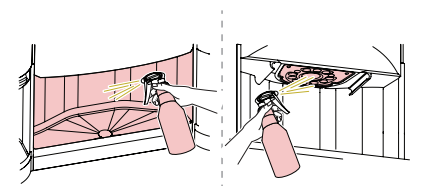

Exterior Cleaning

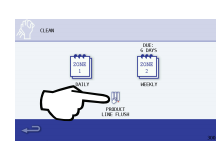

Product Line Flush

NOTE: The following procedures are the basic product line flushing instructions. On-screen instructions can vary depending on the recipe that was created with the MenuConnect program or options chosen in the Managers Menu.

The Product Line Flush procedure allows a user to choose which lines to flush instead of being forced to flush every product line in the unit.

These items are optional and may not be displayed on all easyToUCH screens during the Product Line Flush procedure

NOTE: Performing the product line flush through this interface procedure will not reset the Zone 2 cleaning countdown timer, Zone 2 cleaning will need to be performed in its entirety in order to reset the counter.

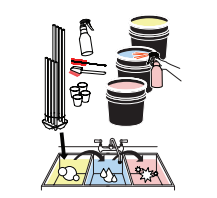

GATHER THE FOLLOWING SUPPLIES

Follow the on screen instructions and gather the following supplies:

If other cleaners are used, it is possible they will not clean or sanitize your machine to NSF standards.

At Back Room Sink

Prepare Cleaning Solutions

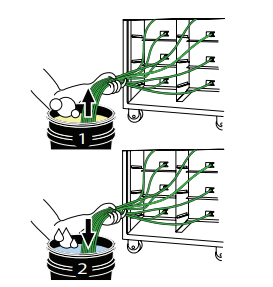

Follow the on screen instructions and fill each labeled bucket to the fill line with the appropriate solution and bring to machine.

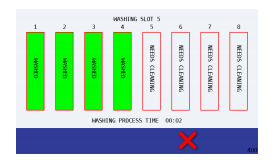

Washing Instructions

Spray and wipe refrigerator surfaces with new sanitized

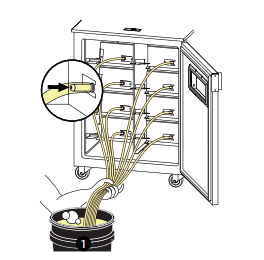

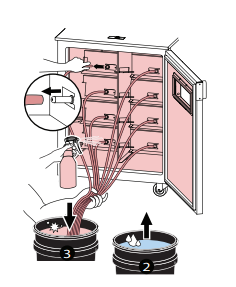

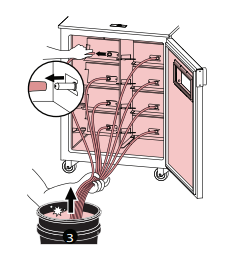

Connect Cleaning Tubes

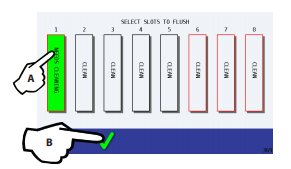

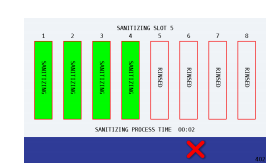

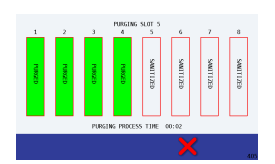

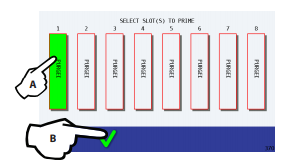

Select Slots to Flush

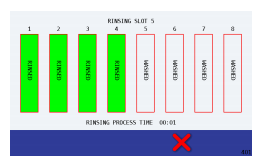

Rinse Lines

Sanitize Lines

Purging Lines

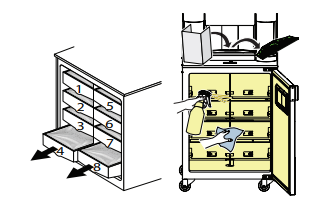

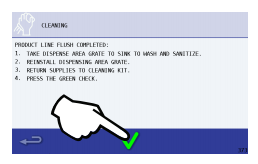

Reinstall Inventory

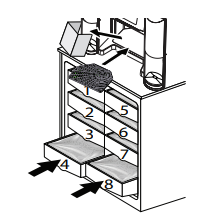

Select Slots to Prime

NOTE: If a line that does not have product assigned was cleaned, it will not need priming.

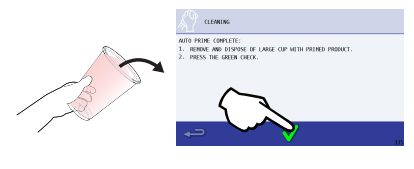

Auto Prime Complete

Importan: Do Not pour down the drain on the BIC unit!

Dispensing Area Cleaning

Important: Do Not Insert a brush or sharp object into the red dispense nozzles.

Dispensing Area Sanitizing

Product Line Flush Completed

Source: Manitowoc (www.partstown.com)