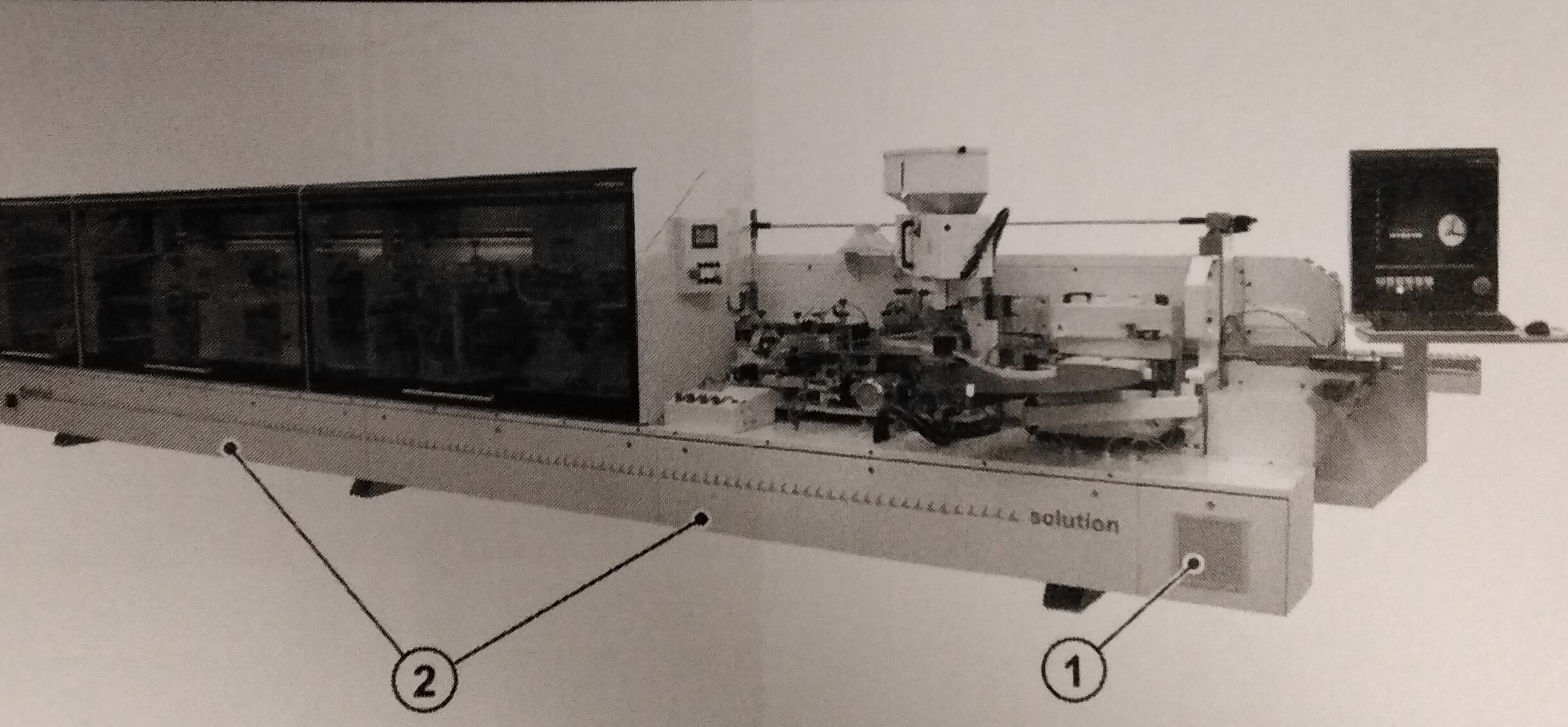

XD - SCM STEFANI SOLUTION

ACL/083/06 - Routine maintenance refers to those operations carried out to maintain operating conditions and proper machine functioning through adjustments, visual inspections, topping off oil levels, etc. Maintenance operations must be performed periodically by the assigned operators and by the maintenance personnel in function of the professional skills and qualifications required.

XD - SCM STEFANI SOLUTION

ACL/083/06 - Routine maintenance refers to those operations carried out to maintain operating conditions and proper machine functioning through adjustments, visual inspections, topping off oil levels, etc. Maintenance operations must be performed periodically by the assigned operators and by the maintenance personnel in function of the professional skills and qualifications required.

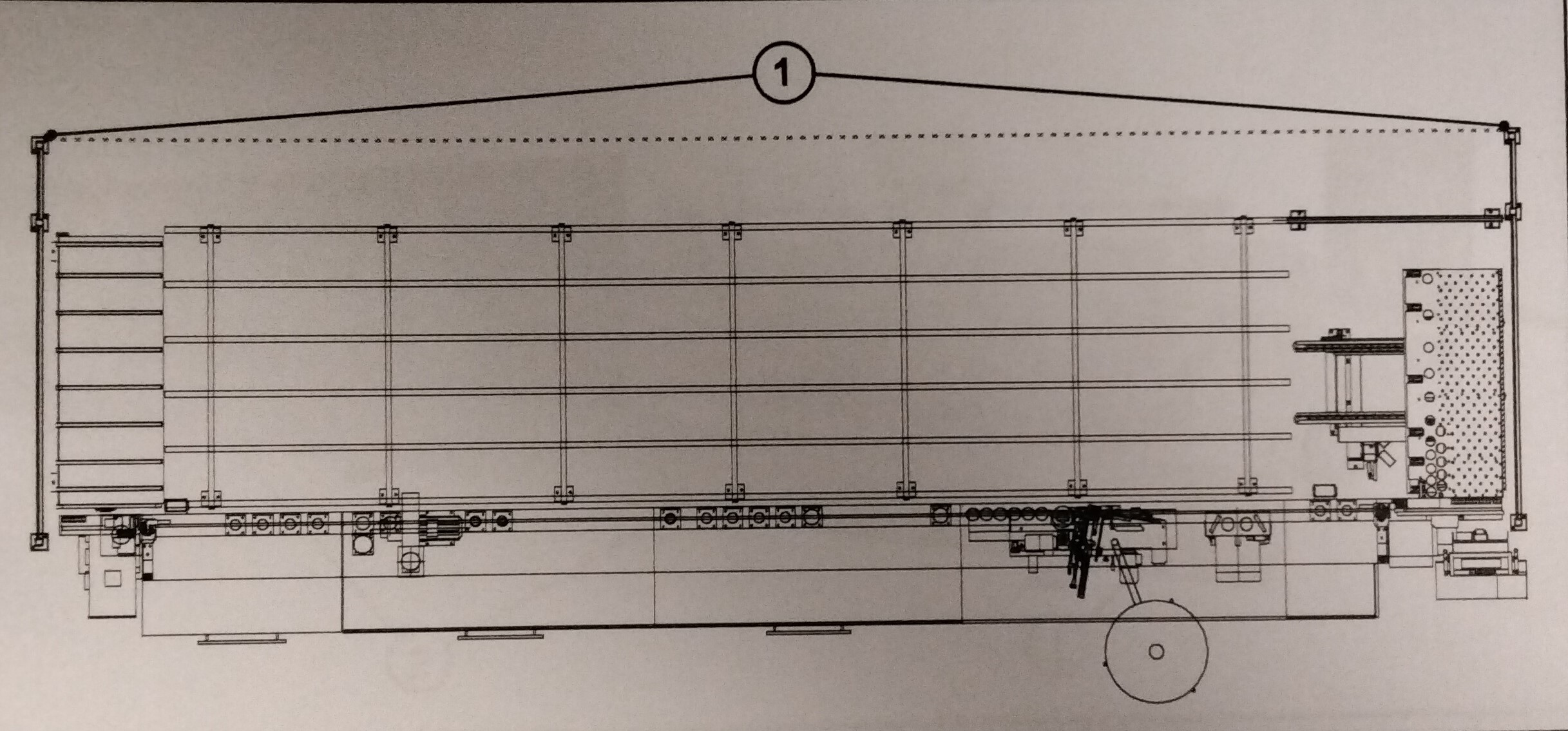

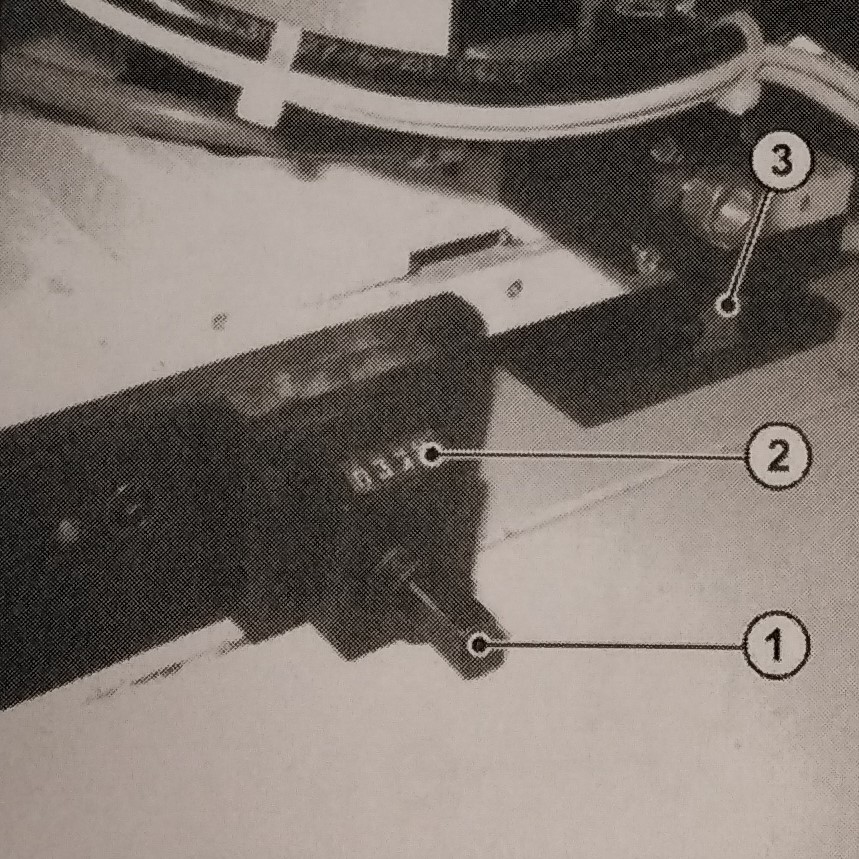

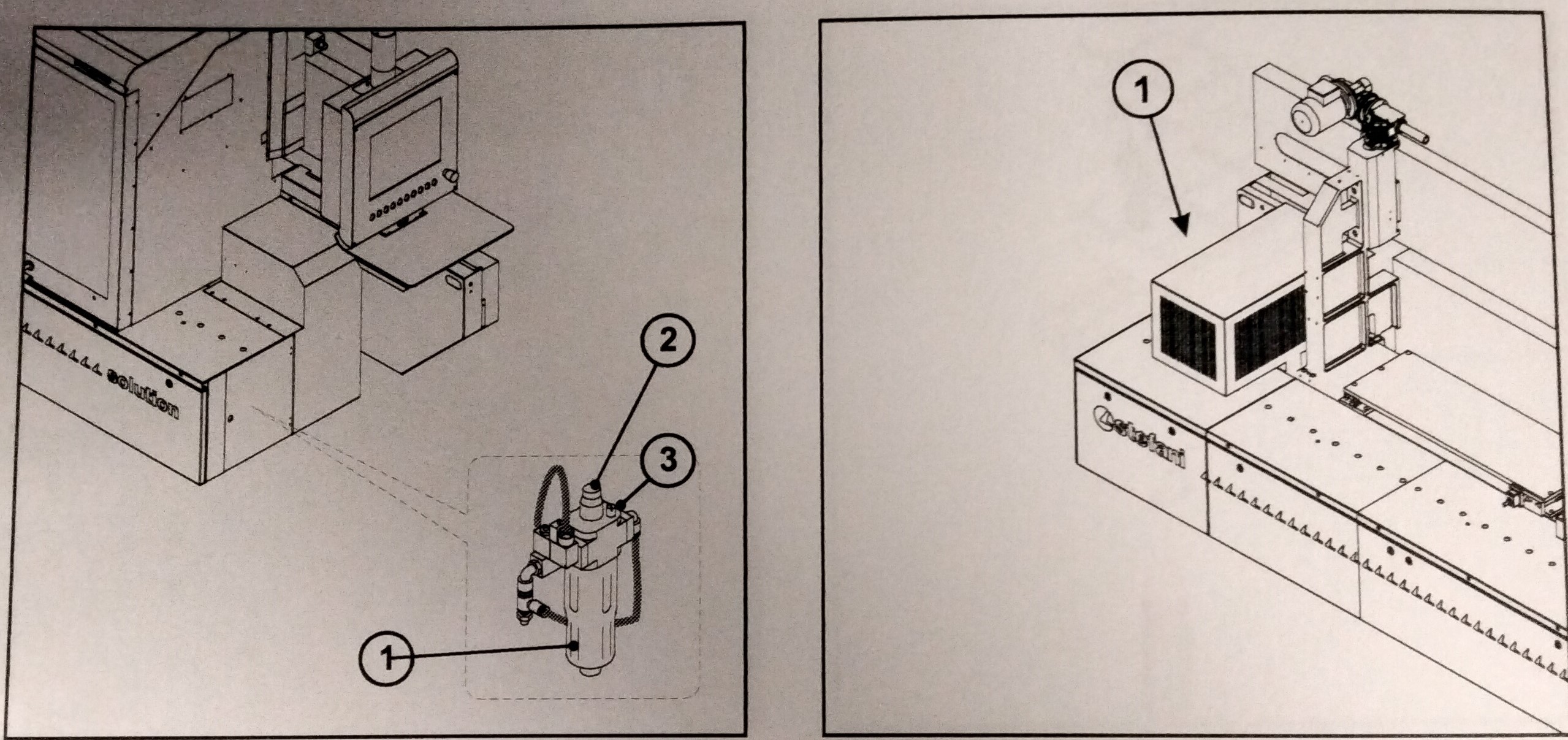

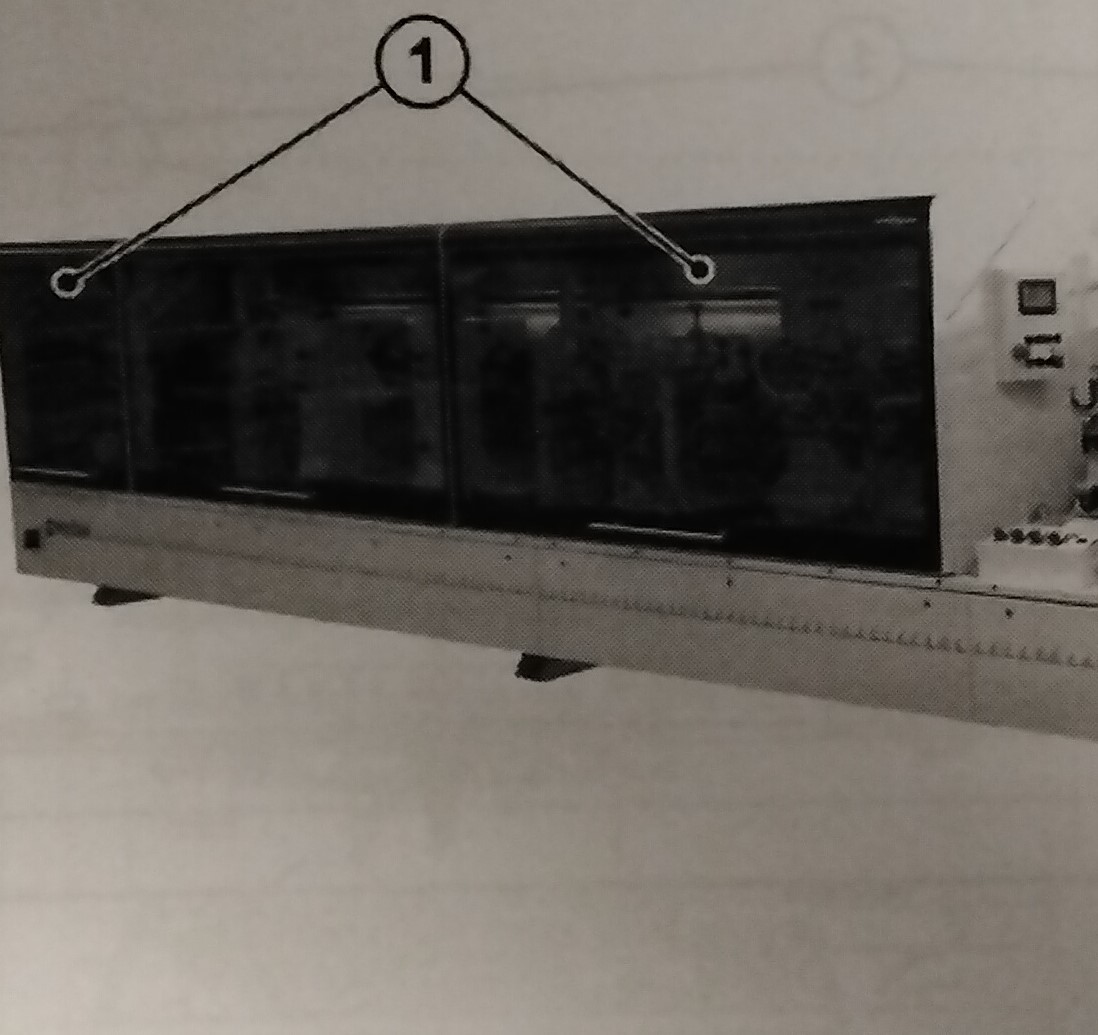

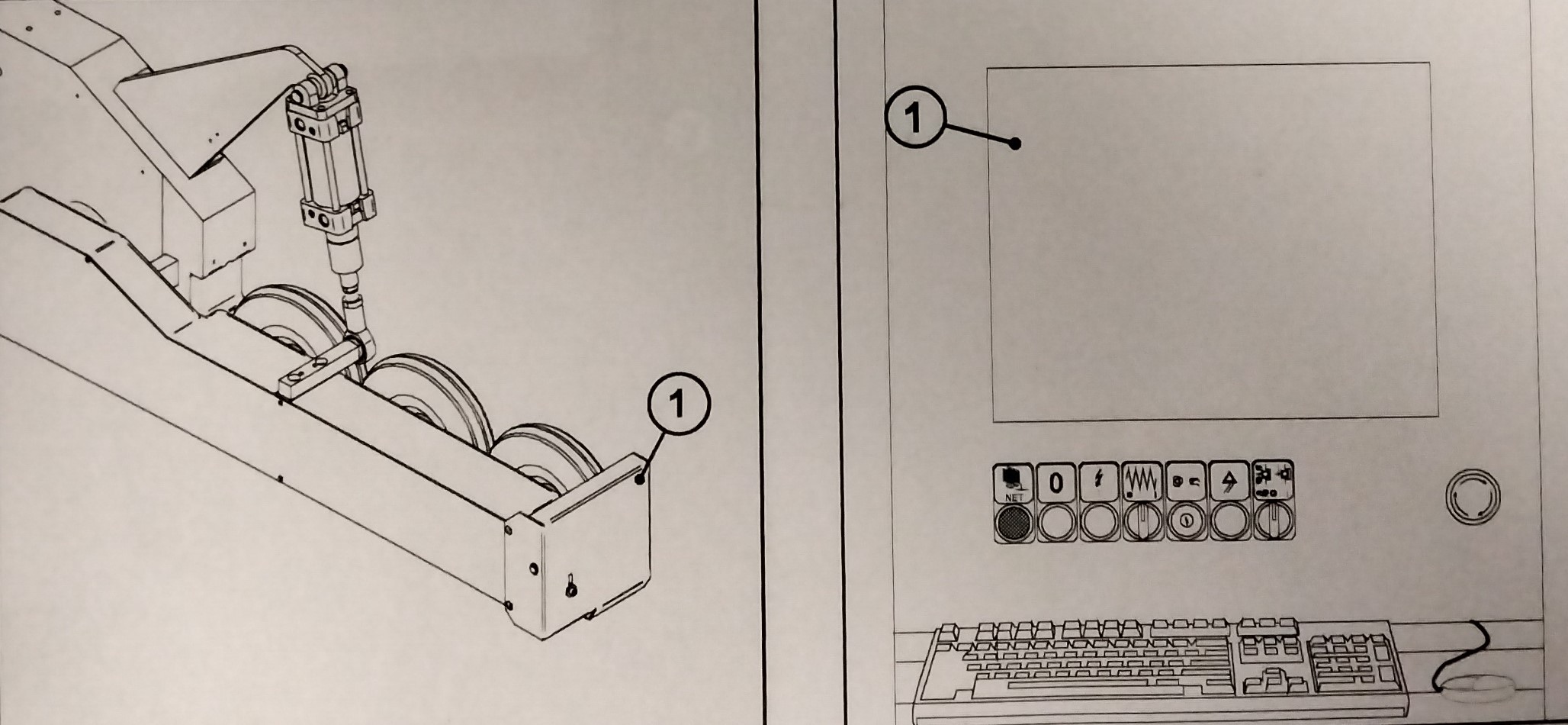

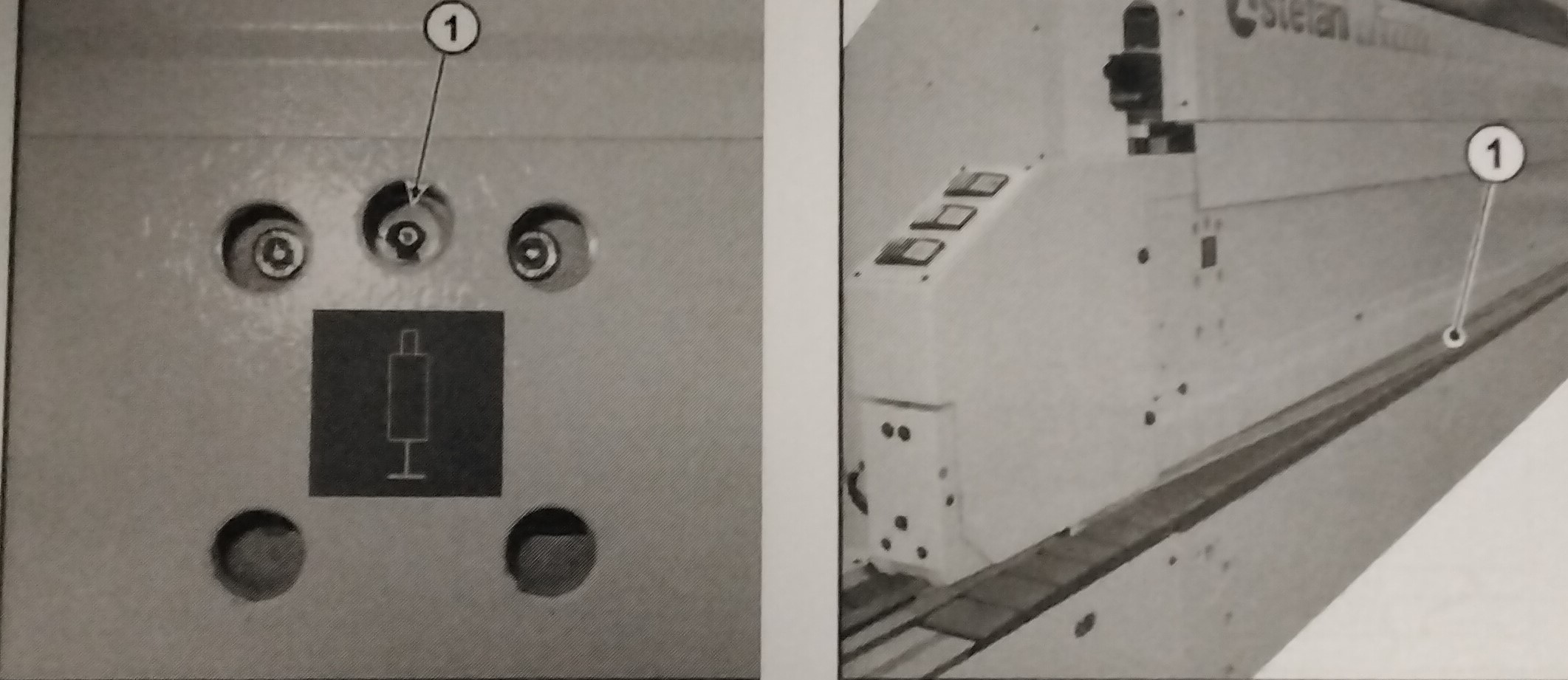

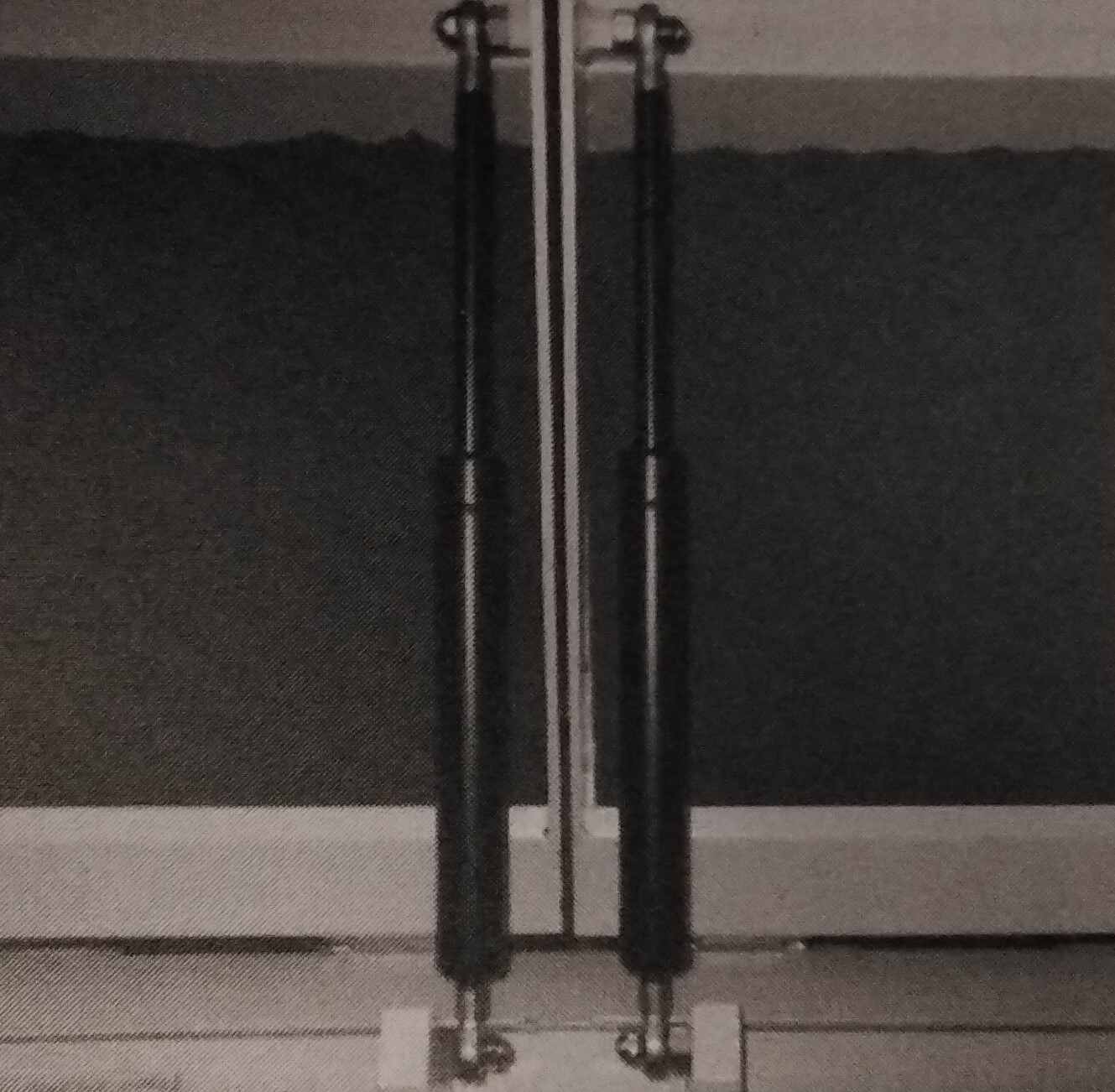

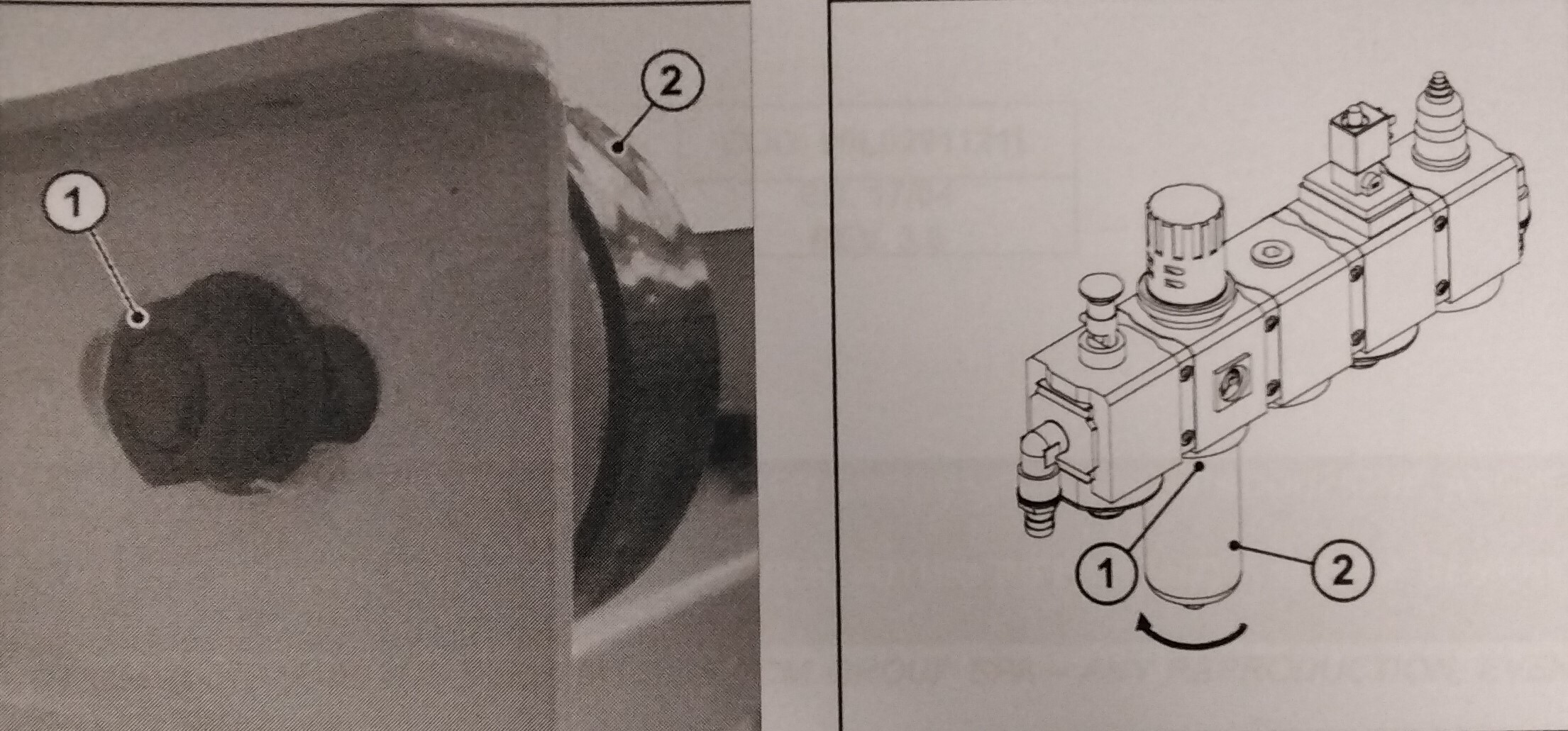

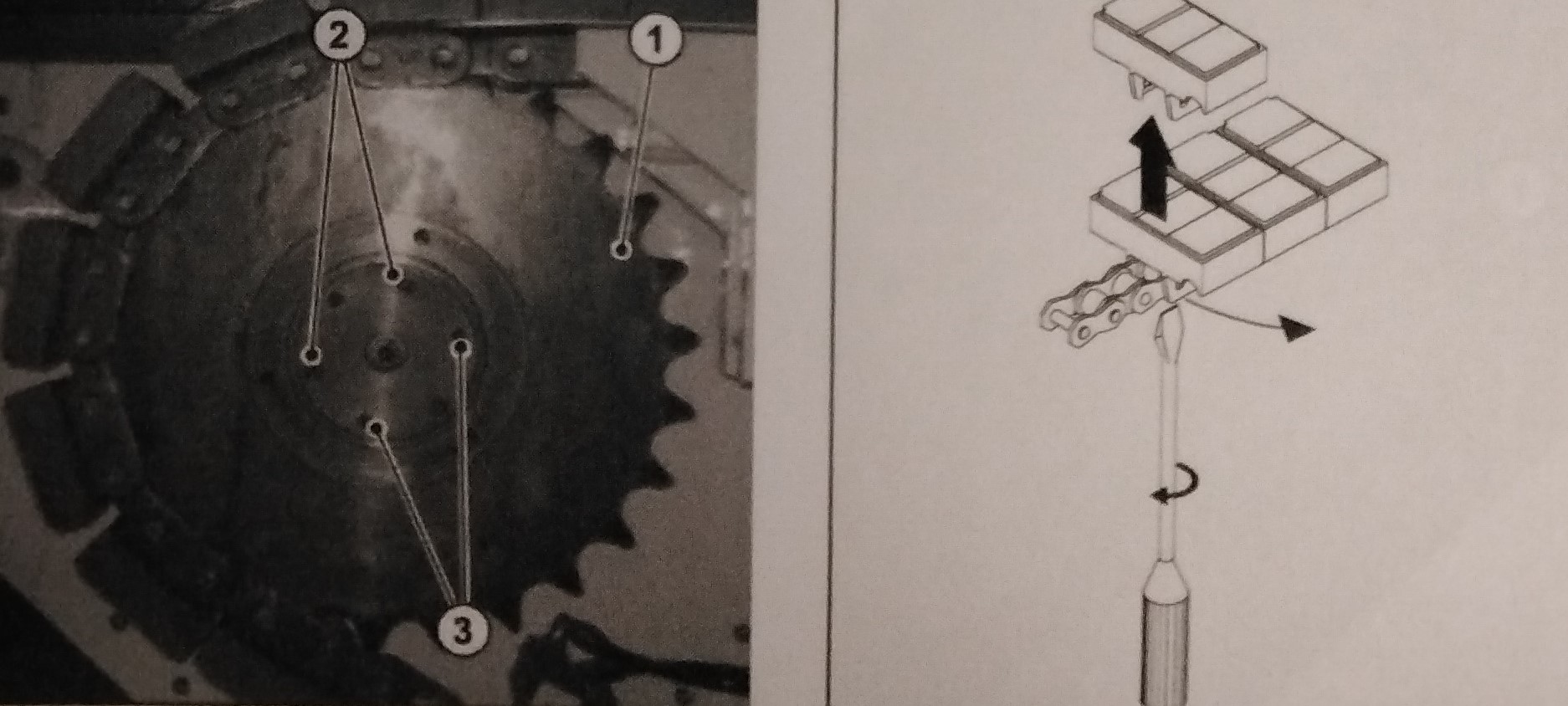

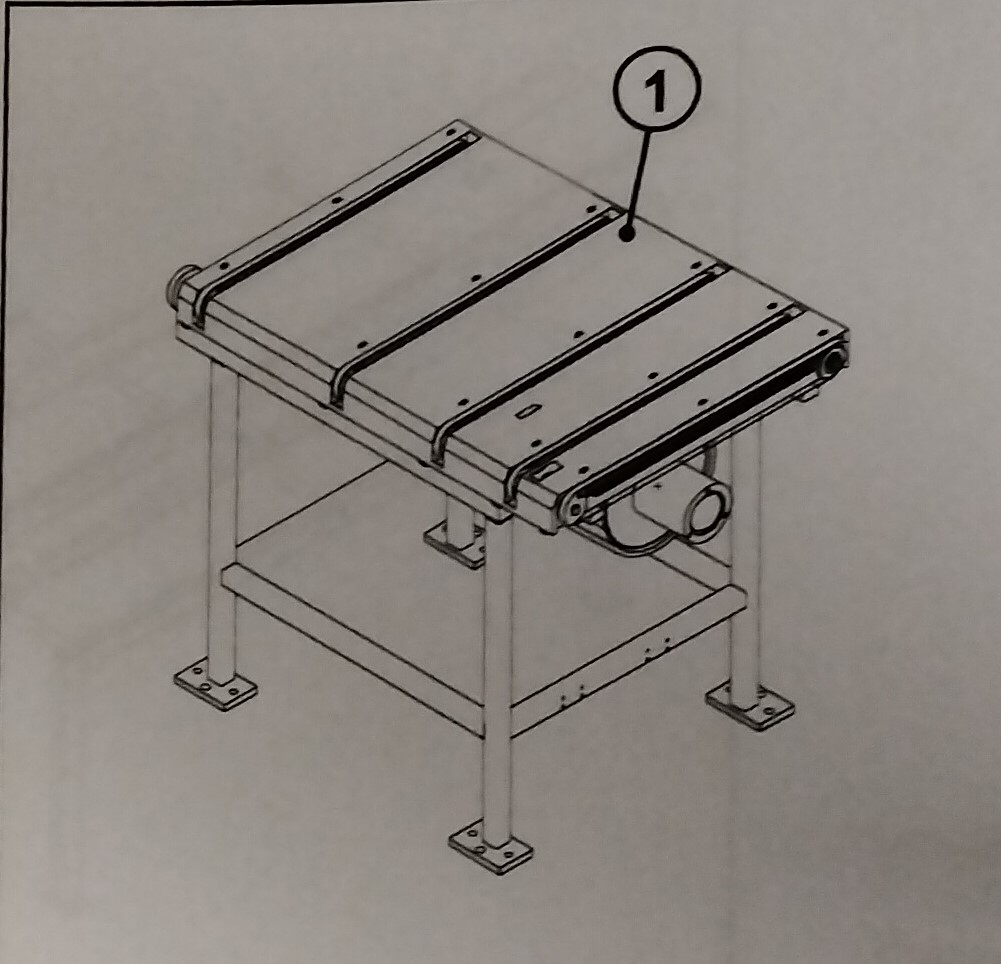

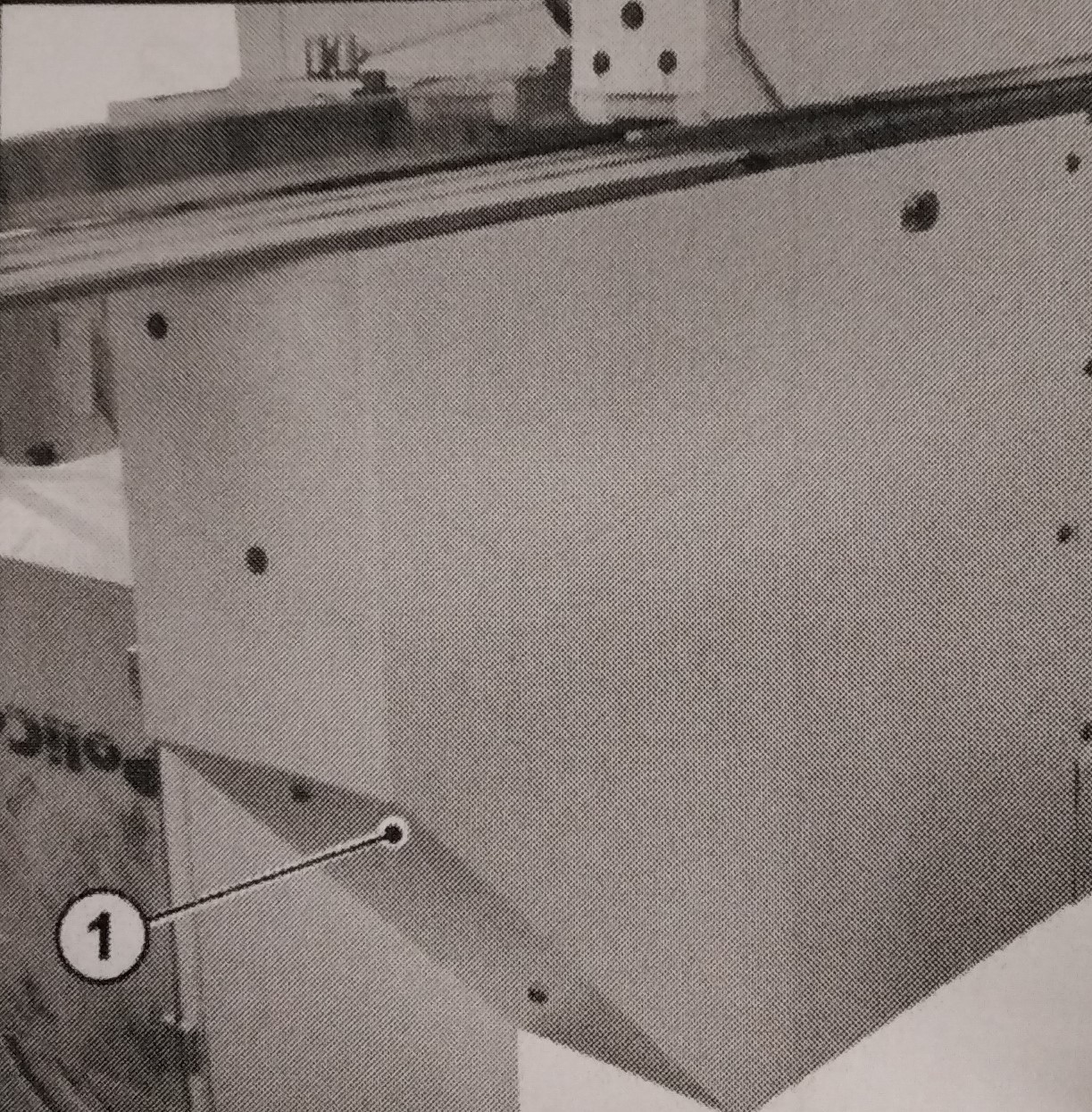

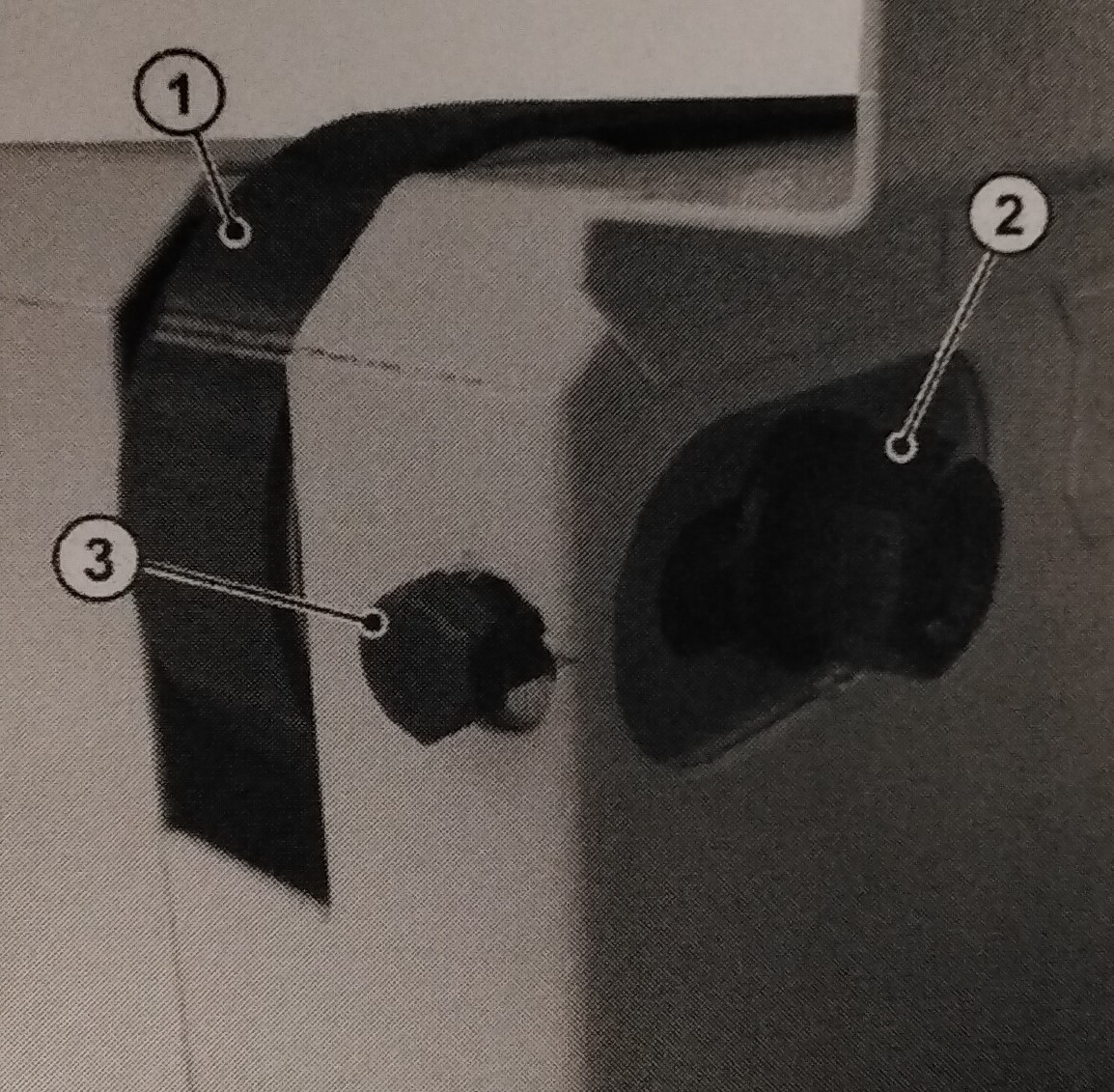

Routine maintenance refers to those operations carried out to maintain operating conditions and proper machine functioning through adjustments, visual inspections, topping off oil levels, etc. Maintenance operations must be performed periodically by the assigned operators and by the maintenance personnel in function of the professional skills and qualifications required. -MACHINE STATUS: Off, with the main switch in the "0" position and padlocked, and the compressed air stop cock closed and padlocked. -OPERATORS: Refer to the chapter and example given in the table. -ONLY USE OIL AND GREASE RECOMMENDED BY THE MANUFACTURER (OR COMPARATIVE PRODUCTS, IF SPECIFIED). -THE USE, FILLING, RECOVERY AND REMOVAL OF EXHAUSTED OIL AND GREASE USED DURING MAINTENANCE MUST BE CARRIED OUT IN STRICT OBSERVANCE OF THE RELATIVE ENVIRONMENTAL STANDARDS IN FORCE. FREQUENCY OPERATION TYPE OF AREA OPERATION ------------------------------------------------------------------------------ 8 hours Machine base Cleaning Extractor tubes drawer Emptying Multibeam barrier Cleaning safety photocells Upper boards Cleaning of the guides with recirculating ball bearing pads Contrast abutment with Cleaning and lubricating the guides panel support (heavy panels) 40 Hours Filters on the electric Cleaning panel Feed track Pads cleaning Feed track Check and top up oil level in lubricator if needed 160 Hours Mobile upper boards Distribution of grease in the guides with recirculating ball bearing pads Upper presser Lubrication of the lifting device 1000 Inside of the electrical Cleaning Hours panel Sound proof cabin doors Gas springs visual inspection Adhesive safety warning Visual inspection labels Emergency stop push Perform a functional test buttons Cord activated emergency Perform a functional test stop devices Sound-proof cabin doors Perform a functional test of the interlocking devices Multibeam barrier safety Perform a functional test. photocells Feeder with wheels Perform a functional test of the protection device Upper pressure Perform a functional test on the guard located at the presser input.

FREQUENCY OPERATION TYPE OF AREA OPERATION ------------------------------------------------------------------------------ 2000 Pneumatic module Replace the filter in cartridge Hours 4000 Feed track Check and top up oil in level Hours gear motor if needed 20000 Feed track Change oil in gear motor Hours 20 Years Machine Integrity check of the safety circuits EXTRAORDINARY MAINTENANCE -Only use original parts (s. spare parts catalogue and electrical diagram) -Arbitrary operations and modifications (or, in any case, other than routine or extraordinary maintenance) are prohibited. Such operations may void any compliance declaration provided by the manufacturer in accordance with the regulations in force. -The machine has been designed and constructed in compliance with state of the art technology and with the laws and standards in force at the time of sale. In the future, if it should become necessary to adapt the machine to comply with new laws and standards, please contact the manufacturer.

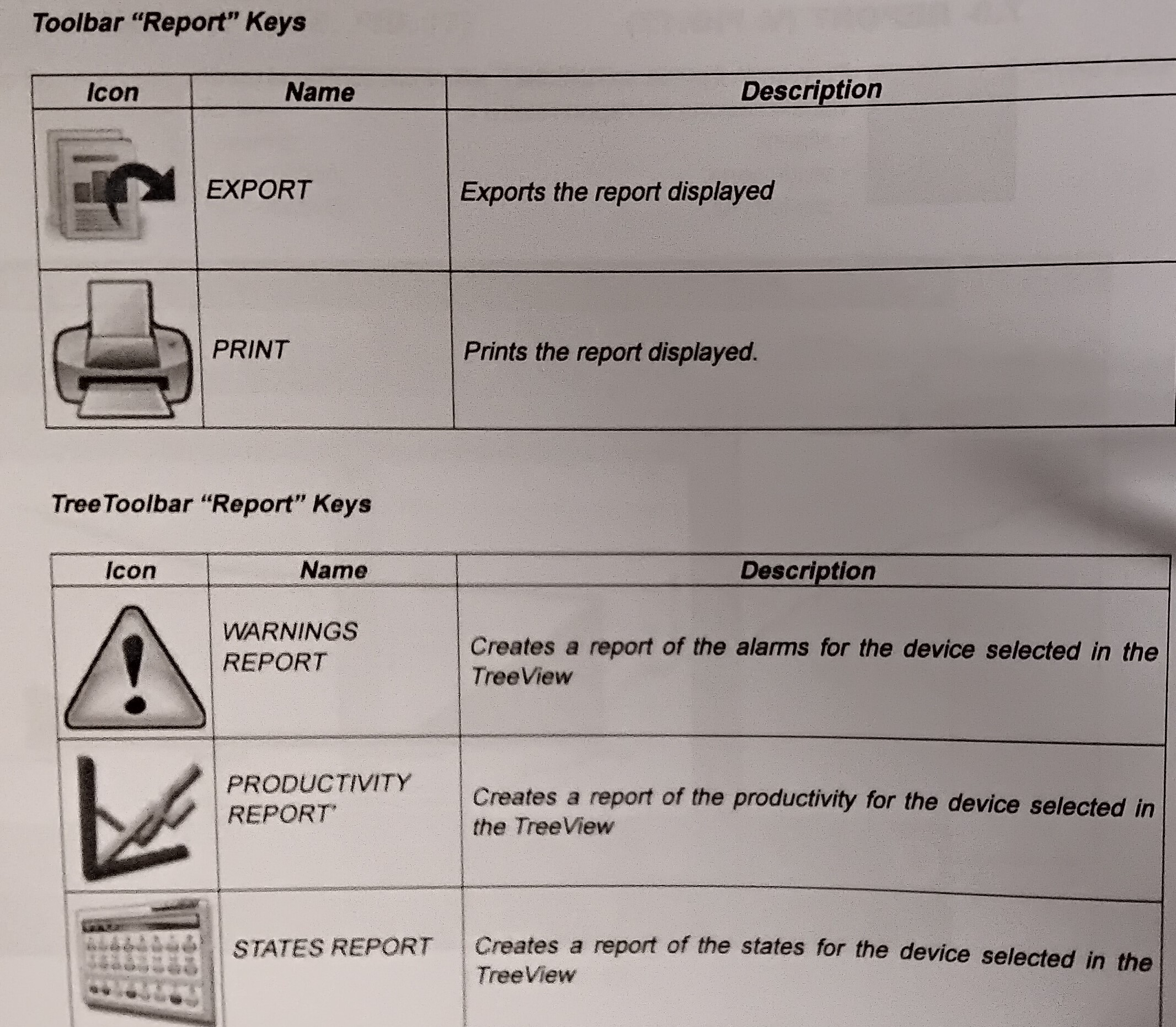

TROUBLESHOOTING

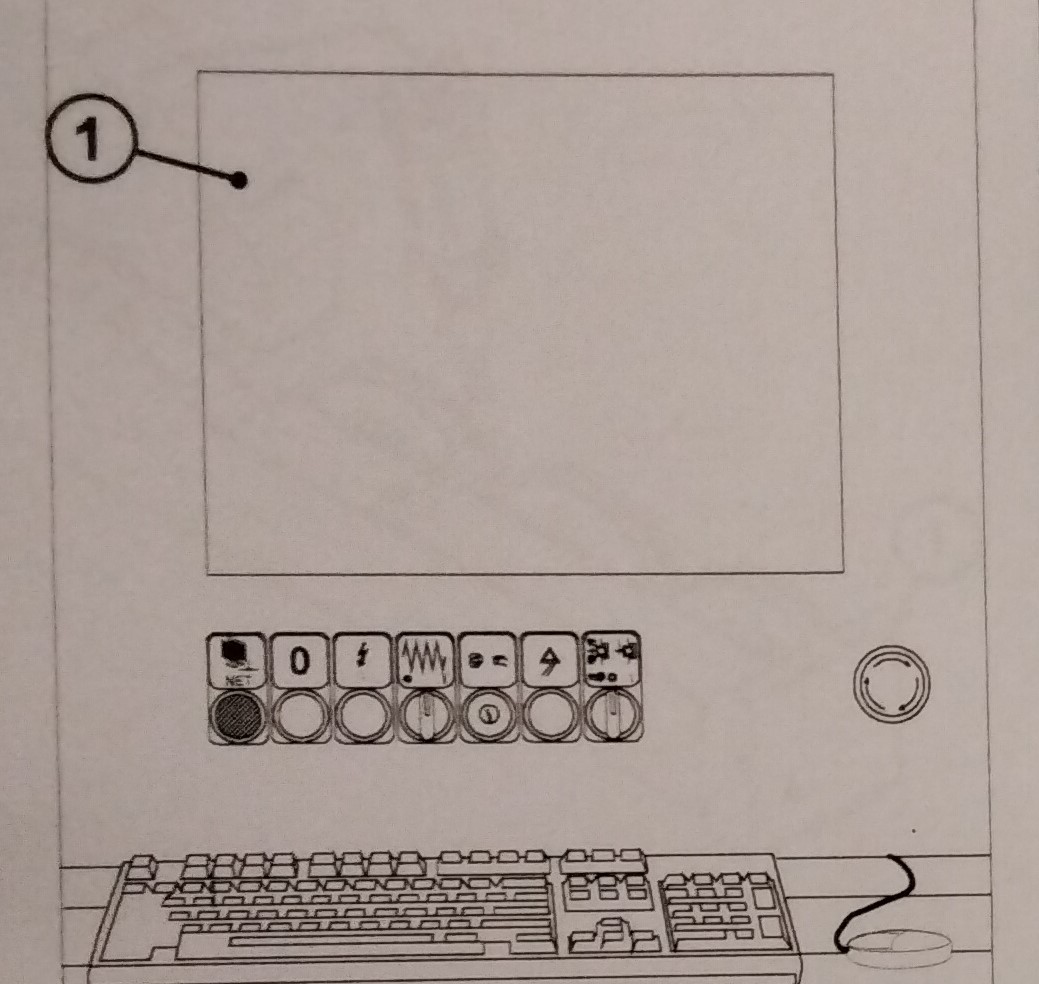

ANOMALIES CAUSE REMEDY -------------------------------------------------------------------------------- No glue on the rear Wrong introduction of Maintain the introduced part or the panel the panel in the machine panel in contact with the entry guide. Auxiliary power -No compressed air -Open the section valve does not start up -Compressed air pressure -Check the compressed air insufficient feeding line on the upper part of the machine. Emergency triggered Reset the emergency mushroom button or emergency cord micro- switch The motors do - The motors have not -Update the program not start been selected by the program -Motors are disconnected -Make connection. from power supply The drive track -Machine in alarm -Read alarm message on does not start conditions graphic terminal display and remove the problem -Gluing working temp- -Wait erature has not been reached. -The glue tank is in pre- -Activate the glue tank heating phase. Feed track and -The operating selector -Proceed as follows: motors do not has remained in the -close, if necessary, the stop (For reasons ADJUSTMENT position door not linked to the for more than 3 minutes -press the auxiliary machining op- erations Power supply button -press the reset alarms button -rotate the operating selector to "Production" mode

Source: Ideal Cabinetry (Community Member)