SP Pump PM

Disassembly, cleaning, and reassembly including torque of screw pump housing and screws, and cleaning material handling

SP Pump PM

Disassembly, cleaning, and reassembly including torque of screw pump housing and screws, and cleaning material handling

Ensure LOTO- All sources of power are disabled, disconnected, or locked out

remove (8x) 8mm allen head capscrews from front air plenum

remove (8x) 18mm nuts from housing to gearbox studs, being careful not to bend the studs or leave the housing unsupported

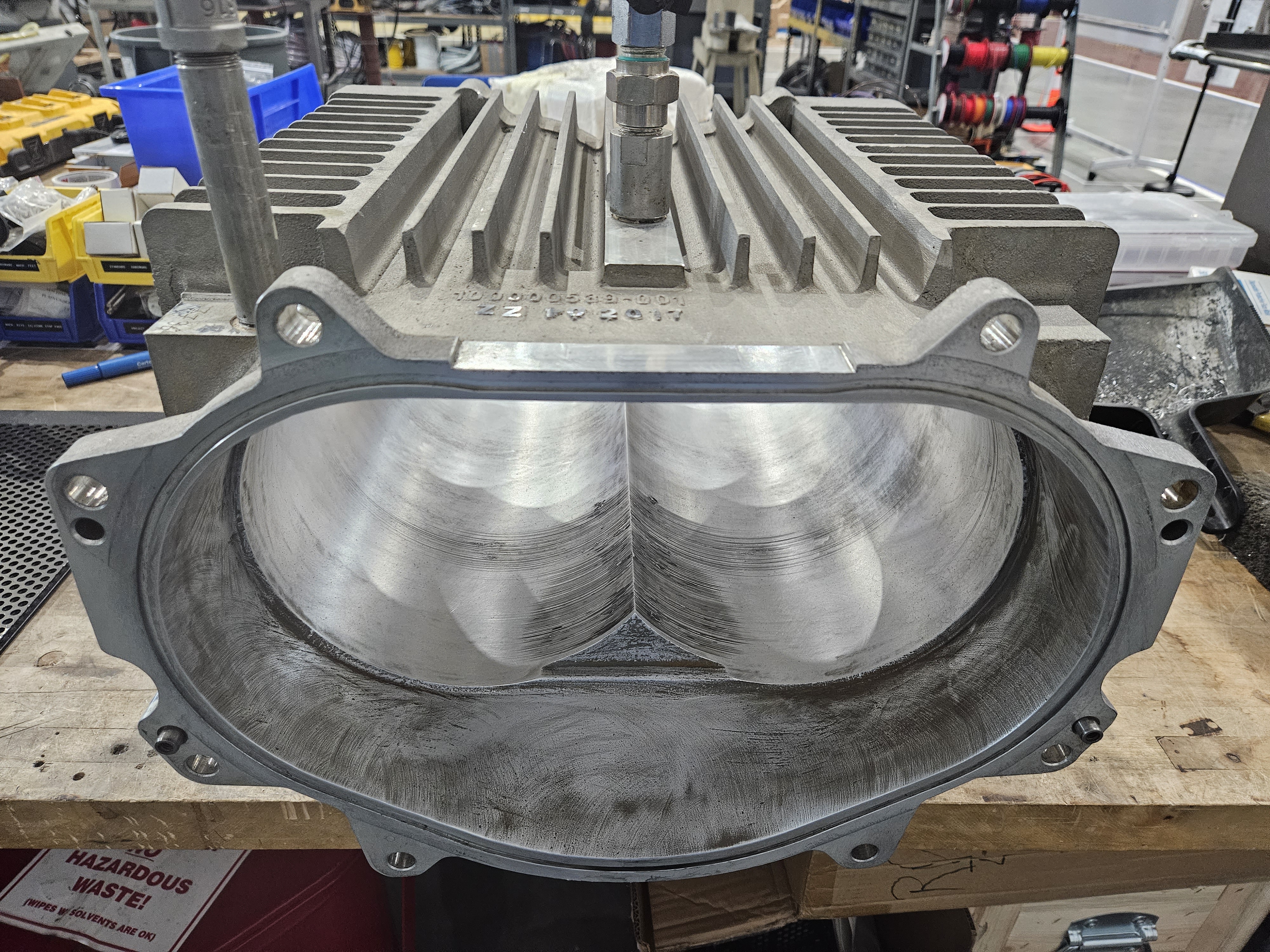

remove aluminum housing from screw pump, and place over absorbent pads

Using scouring pads (3m scotchbrite as example) and isopropyl, remove debris, remnants, and particles from housing, to include O-Ring seats, and housing flanges on both ends

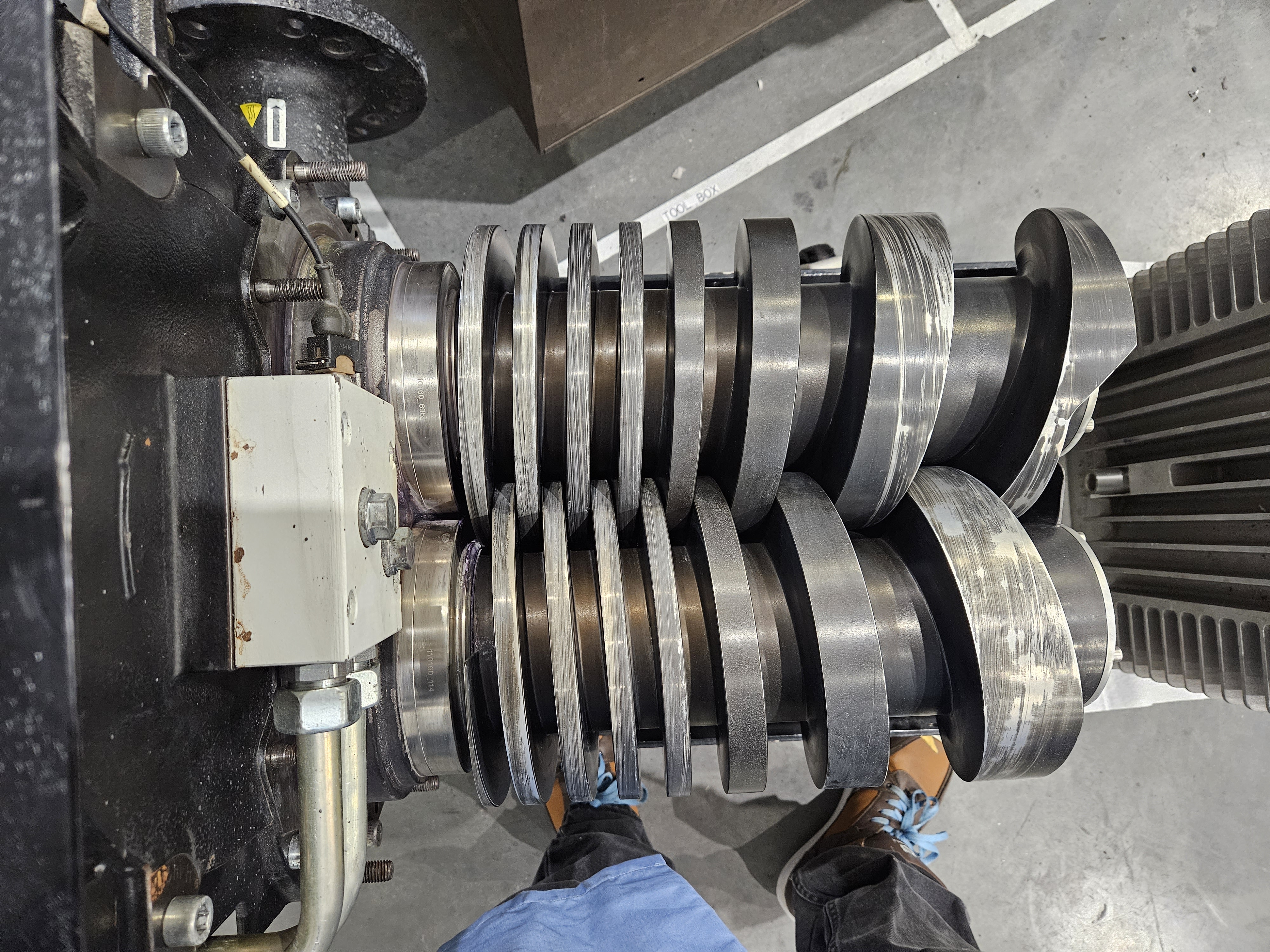

Place absorbent pads beneath pump screws. Using Scouring pads (3m scotchbrite as example) and isopropyl, remove debris, remnants, and particles from the screws

Inspect both O-Ring seals for damage, tears, splits, or dry rotting

With both O-Ring seals in good condition, lubricate with high-vacuum grease (dow corning)

Reinstall housing, installing nuts until hand tight, then following a double-star pattern, torque nuts to 25'-lbs initial, 45'-lbs final torque

reinstall, and retorque front air plenum using the same double-star torquing pattern, and the same 25#-45# torque

Check for proper function,and rotation by reinstalling power cable if necessary, and tag as cleaned/PM performed, noting your name, the date, and torque of bolts

Source: Superpower-inc. (Community Member)